Processing technology for drilling holes without drill jig with accurate pitch

A processing technology and precise technology, applied in the field of processing holes, can solve the problems of inconvenient clamping, high distance between small holes, large consumption, etc., and achieve the effects of reducing production costs, ensuring product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

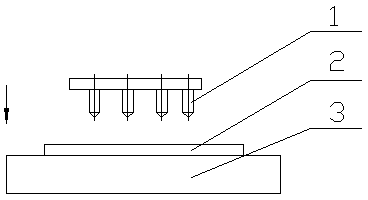

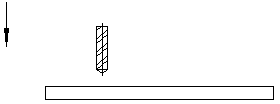

[0014] Referring to the accompanying drawings, a drilling process without a drilling die with precise hole spacing, 1) Process the stamping die according to the drawing requirements; 2) First punch a conical pit at the position required by the drawing drawing that needs to be drilled; 3) Then drill holes directly against the tapered pit position. During the specific implementation, first process the stamping die according to the requirements of the drawing, place the workpiece 2 on the lower template 3 of the stamping die, after positioning and installing, adjust the size of the punching conical pit, punch the pit punch 1 and then punch it, and punch it Finally, the workpiece is removed, and then the workpiece is placed on the drill press and drilled directly against the conical pit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com