Automobile flexible pipe cutting machine

A technology for cutting machines and hoses, applied in the direction of pipe shearing devices, shearing devices, and accessories of shearing machines, etc., can solve the problems of poor product consistency, low cutting precision, and high labor intensity, and achieve good consistency, High cutting precision and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

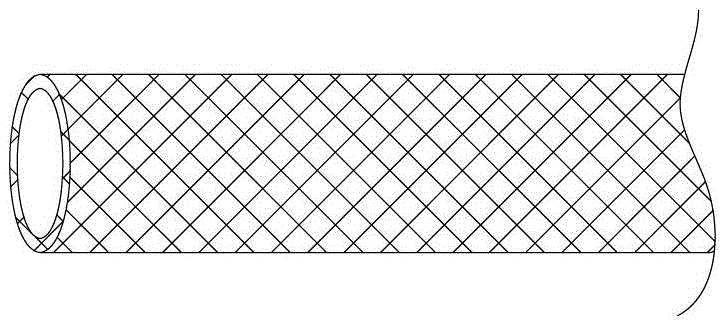

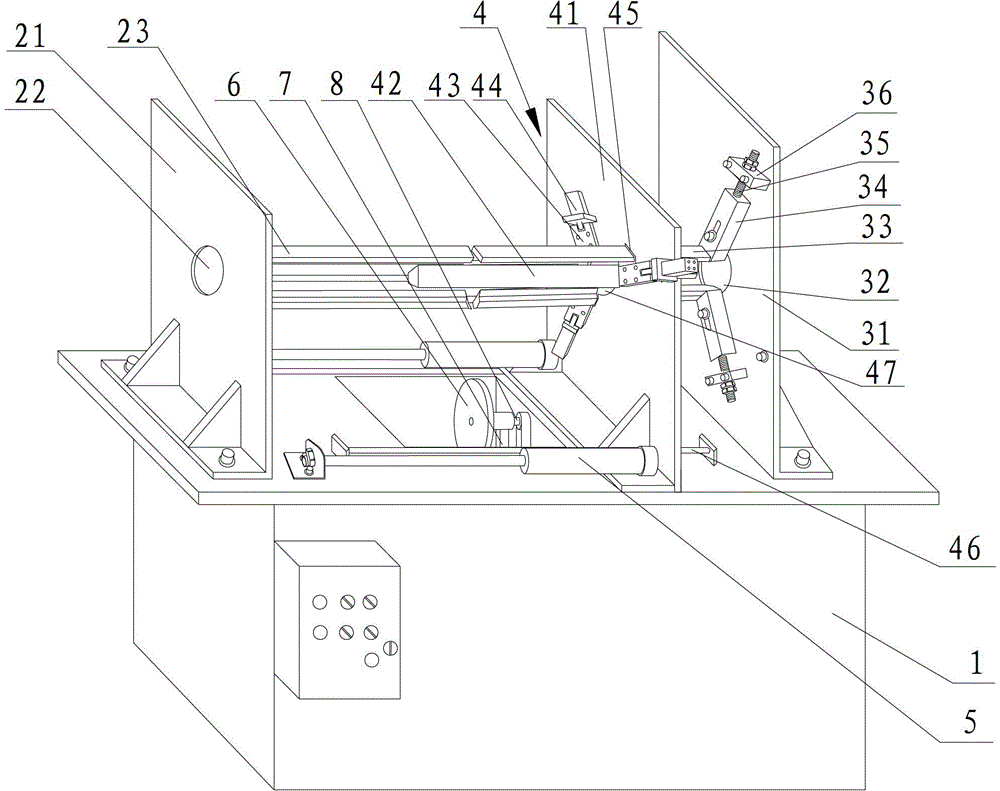

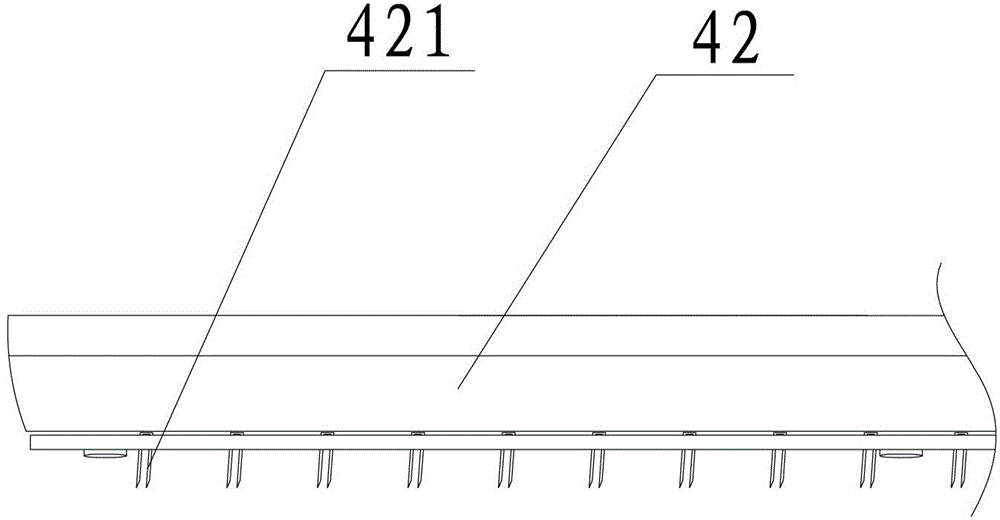

[0018] see figure 1 Shown is a schematic diagram of the structure of an automotive hose to be cut, which is a mesh structure woven by countless filaments. Figure 2~3 Shown is an automobile hose cutting machine for cutting this type of hose, which includes a support base 1, a first material guide base 21 and a second material guide base 31 fixedly arranged at both ends of the support base 1 , the first material guide seat 21 is provided with a first through hole 22, the second material guide seat 31 is provided with a second through hole 32, and the center lines of the first through hole 22 and the second through hole 32 are all along the horizontal left and right directions Extending, the hose can be threaded axially into the first through hole 22 and the second through hole 32 . The horizontal left-right direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com