Centrifugal rotary cutting mechanism for thermal shrinkage pipe

A heat-shrinkable tube and cutting technology, which is applied in metal processing and other directions, can solve the problems of oblique cutting and uneven cutting, and achieve the effect of improving cutting production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

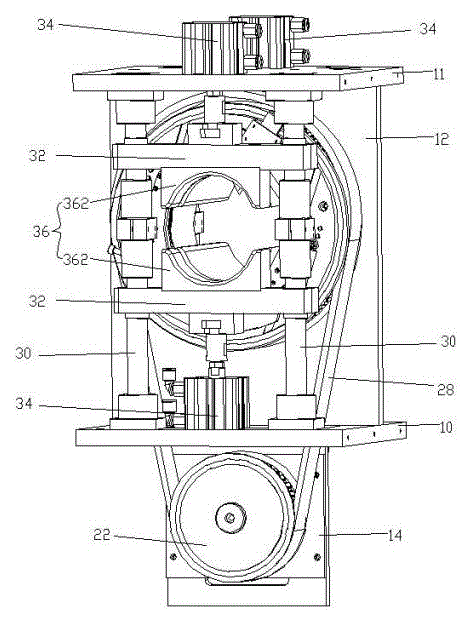

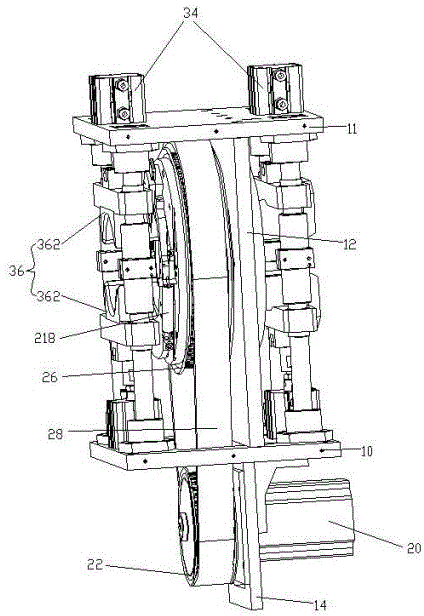

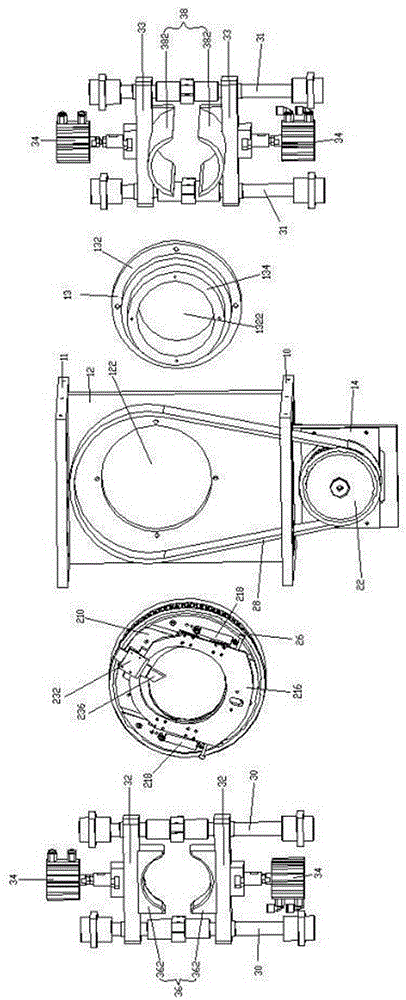

[0031] see Figure 1 to Figure 11 , a centrifugal rotary cutting machine for heat-shrinkable tubes, which includes a frame (not labeled), a clamp mechanism (not labeled), and a centrifugal rotary cutting mechanism (not labeled).

[0032] The frame (not labeled) includes a support plate 12 , a support seat 13 , and a motor mounting plate 14 .

[0033] The support plate 12 is installed vertically. A circular through hole 122 is defined on the support plate 12 .

[0034] The support seat 13 includes a circular seat body 132, a circular through hole 1322 is opened in the center of the seat body 132, and a circular bearing mounting seat protrudes along the edge of the through hole 1322 on the seat body 132. 134. The supporting seat 13 is fixed on the supporting plate 12 , and the bearing mounting seat 134 passes through the through hole 122 .

[0035] This fixture mechanism (unlabeled) comprises a bottom plate 10, a top plate 11, two front guide pillars 30, two rear guide pilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com