A flexible and configurable guide wire and a manufacturing method thereof

A flexible and guide wire technology, applied in the field of medical devices, can solve the problems of high production cost, complex production process, poor solder biocompatibility, etc., and achieve the effect of reduced manufacturing cost, simple processing technology and better compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

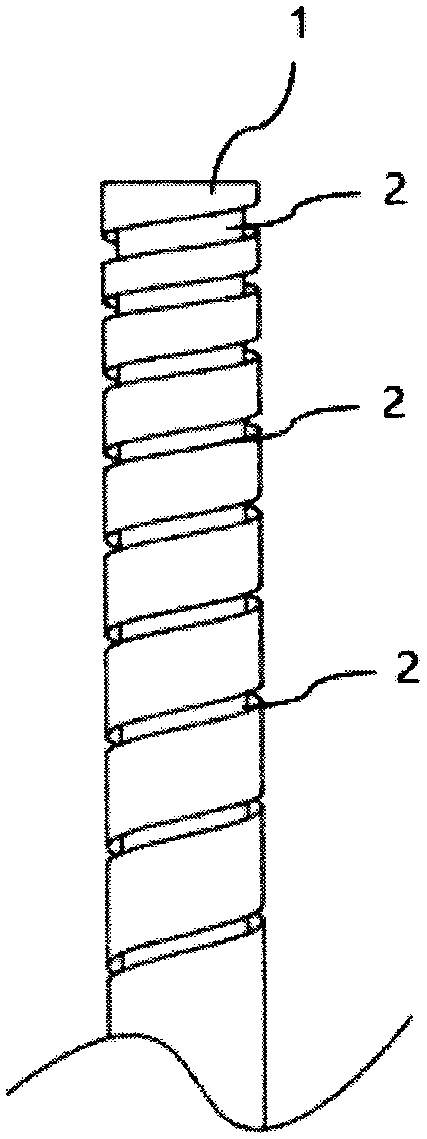

[0038] Such as figure 1 As shown, a plurality of groove units 2 are arranged in a spiral structure, and the shape of the groove units 2 is straight. The plurality of groove units 2 are connected end to end, and finally the plurality of groove units 2 form a helix on the outer surface of the metal wire 1 . In order to make the flexibility of the guide wire meet the required requirements, the pitch of the helix can be adjusted, and the smaller the pitch, the better the flexibility.

Embodiment 2

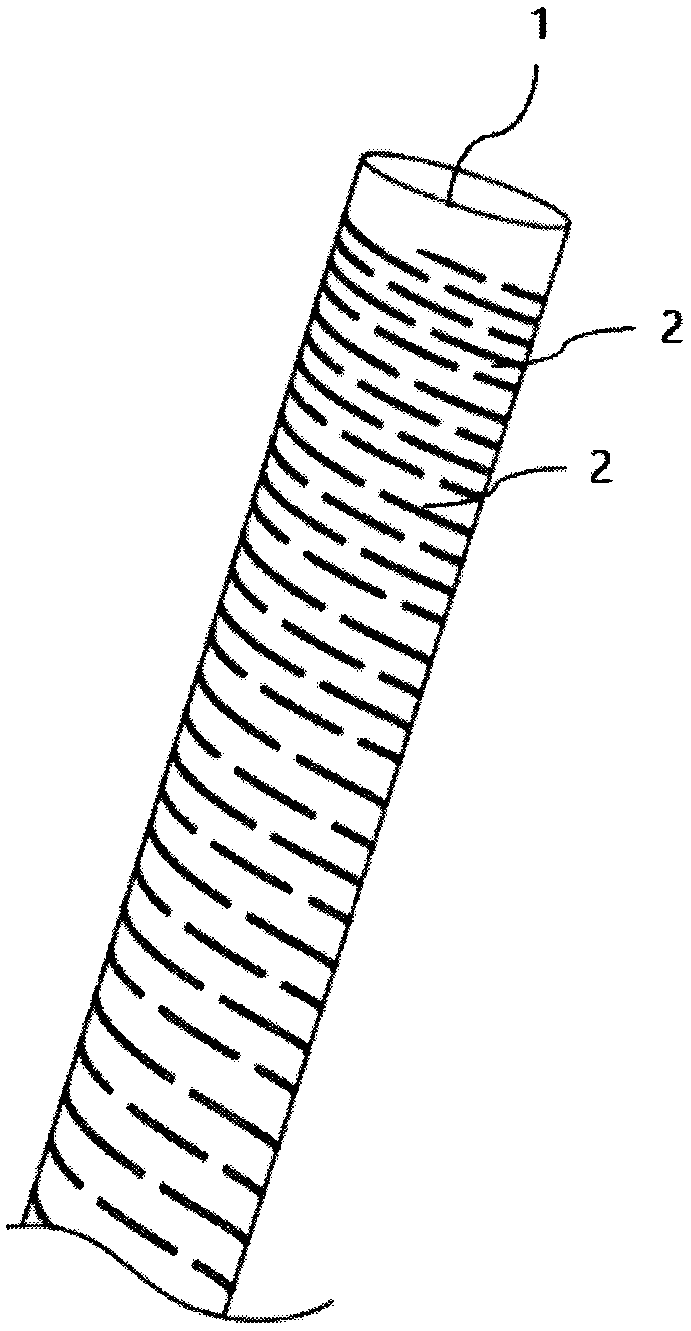

[0040] Such as figure 2 As shown, a plurality of the groove units 2 are arranged in a double-start thread-like structure, the shape of the groove units 2 is linear, and a plurality of the groove units 2 are arranged at intervals from each other, and the groove units The groove depth of 2 is greater than the radius of the metal wire 1 and smaller than the diameter of the metal wire 1 . The double-threaded structure is mirror-symmetrically arranged with respect to the axial section of the metal wire 1. When there are groove units at the same axial position of the metal wire 1 at a distance of 180 degrees, the opposite groove unit is The slits are interconnected to form slits; in this way, there are three states in the axial direction of the metal wire 1: uncut, a single groove unit, and slits formed by opposite groove units. By changing the proportions of these three states on the wire 1, the flexibility of the guide wire can be set.

Embodiment 3

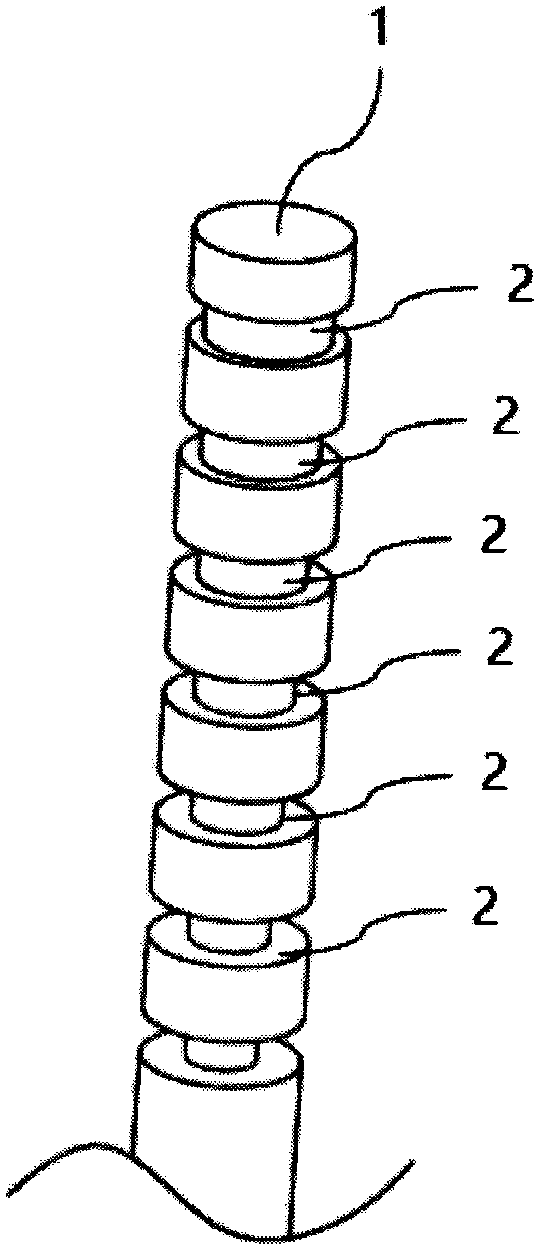

[0042] Such as image 3 As shown, a plurality of the groove units 2 are arranged into a plurality of ring structures, the shape of the groove units 2 is straight, and the plurality of groove units in the same ring structure are connected end to end , and finally form a plurality of annular grooves on the outer peripheral surface of the wire. The surfaces formed by the ring structures are planes parallel to each other, and the distances between them are equal. The groove width of the groove unit is fixed and smaller than the diameter of the metal wire 1 . The groove depths of the groove unit 2 are different and smaller than the radius of the wire. The deeper the groove depth is, the better the flexibility of the metal wire is, and the flexibility of the guide wire can be set by adjusting the depth of the groove unit 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com