Porous perforating device

A technology of punching device and mounting plate, applied in metal processing and other directions, can solve the problems of inability to implement design and lack of multi-hole punching equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] In this embodiment, two water outlet holes are punched on each dripper of the drip irrigation pipe as an example for illustration, but the multi-hole punching device of the present invention is not limited thereto, and the multi-hole punching device of the present invention is suitable for high-speed continuous The production line can punch out multiple orifices in a specific area according to the set distribution for long items.

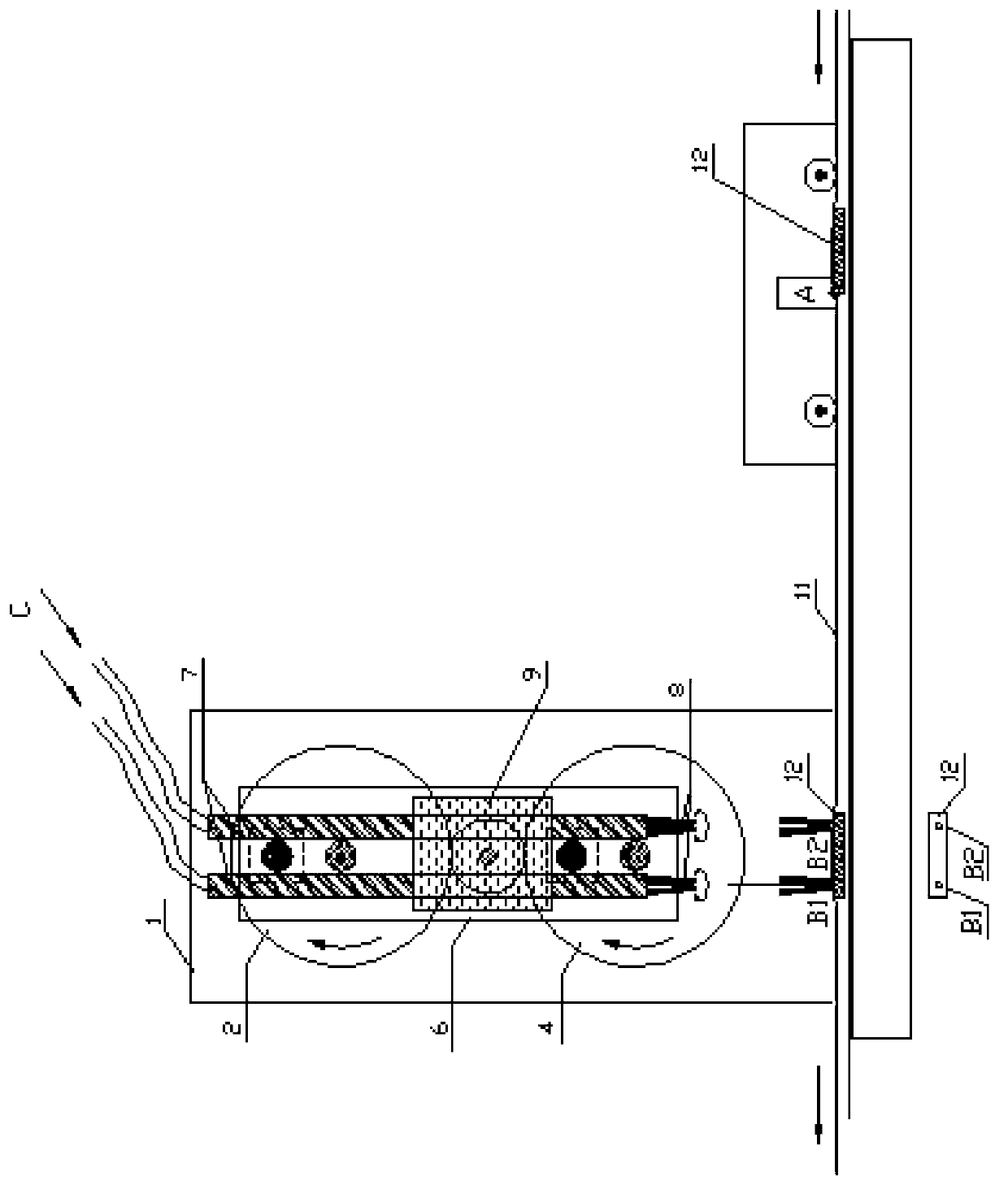

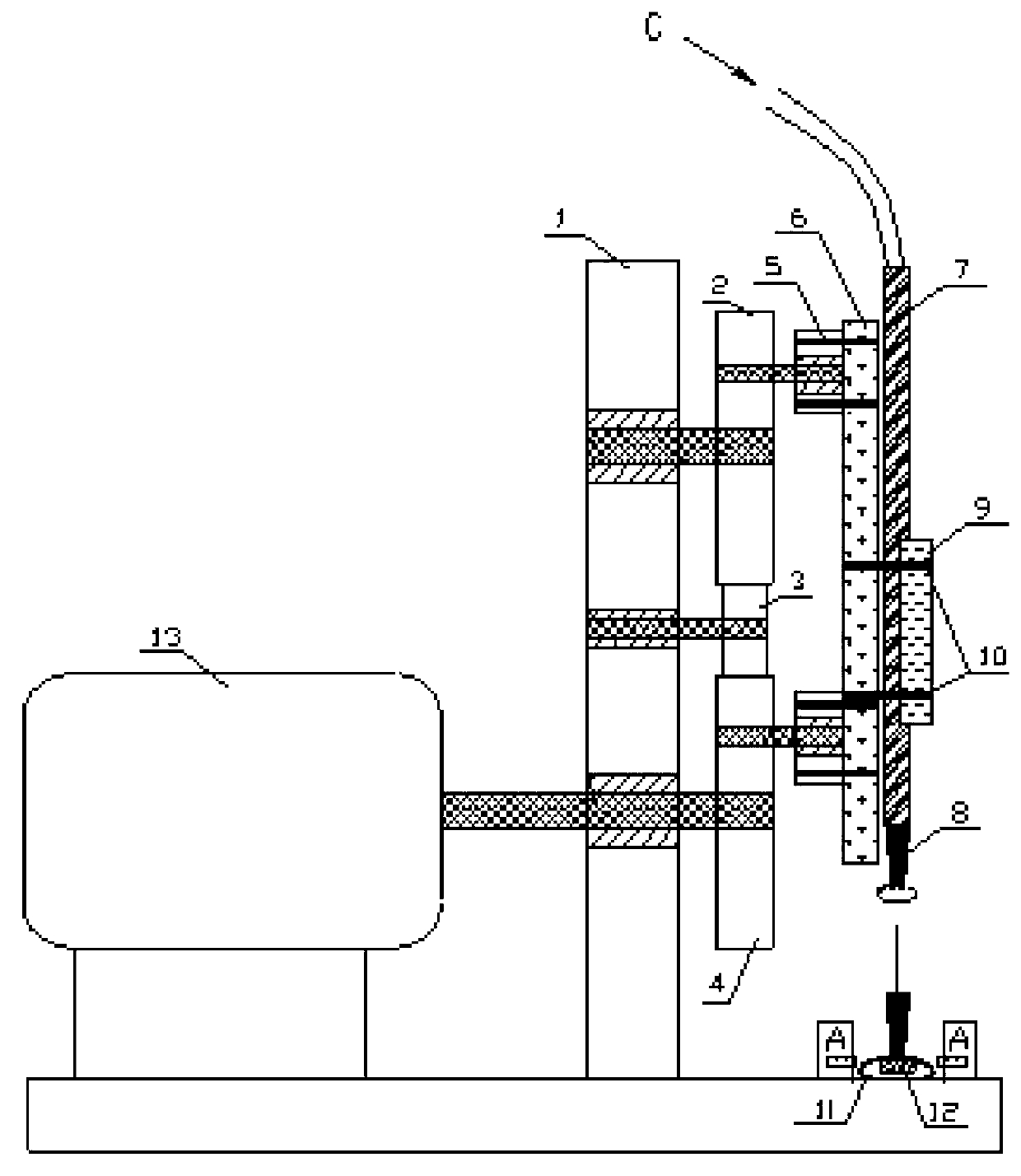

[0027] Such as figure 1 As shown, a multi-hole punching device provided in an embodiment of the present invention is used to punch holes for articles, and the multi-hole punching device includes a motor 13, a transmission mechanism, an actuator and a track connected in sequence;

[0028] The transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com