Clean energy electric saw with functions of energy conservation and emission reduction

A clean energy, energy saving and emission reduction technology, applied in circular saws, sawing equipment, wood processing appliances, etc., can solve the problems of large investment losses, serious pollution, huge investment in power transmission facilities, etc., and achieve the effect of frictionless work and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

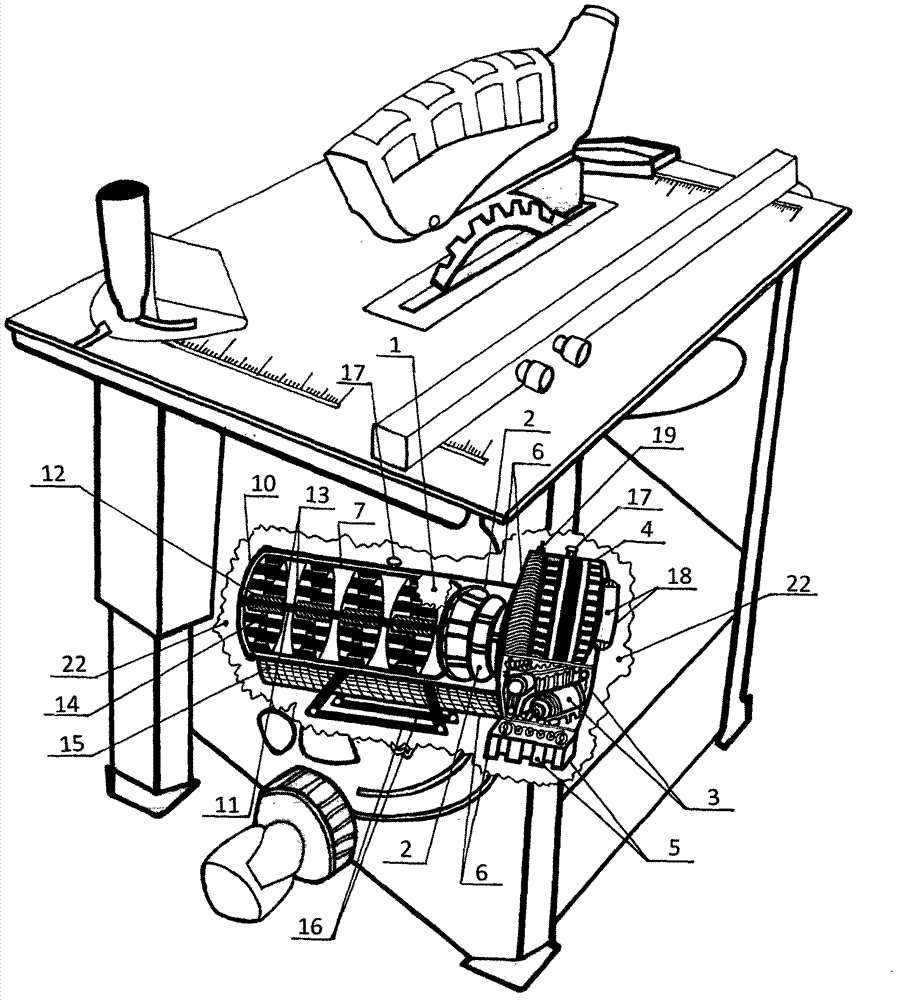

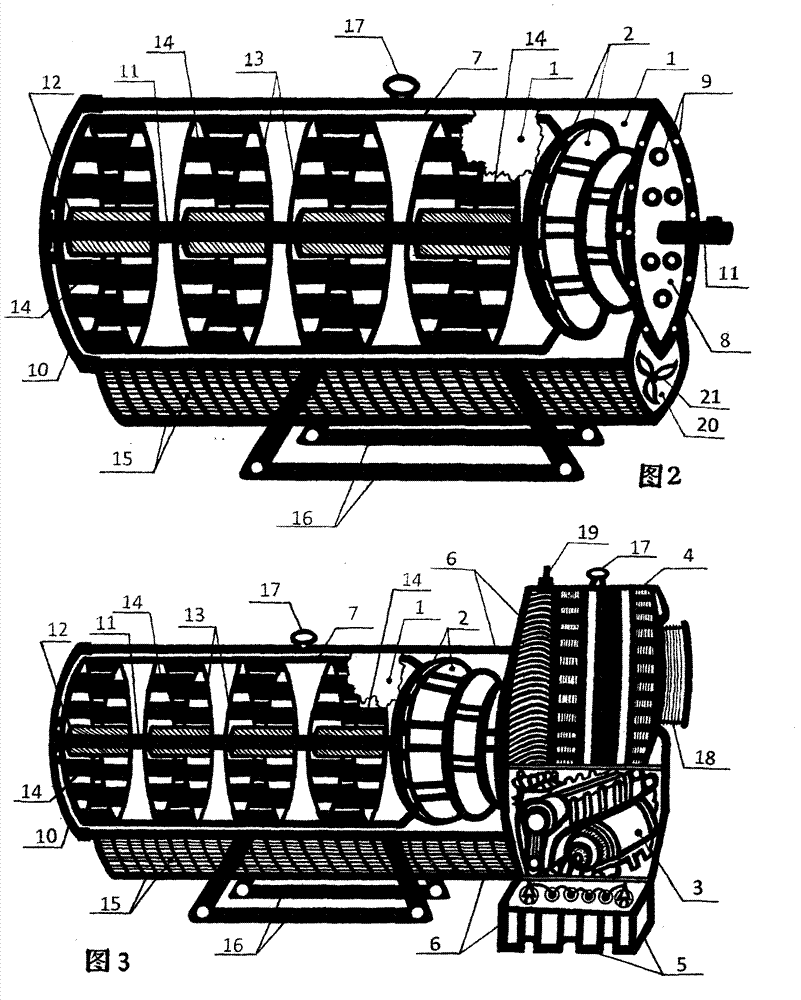

[0033] Here is a detailed description of the structure of an energy-saving, emission-reducing clean energy power chainsaw in conjunction with the attached drawings:

[0034] See figure 1 , 2 , First of all, install a force-by-force and constant-motion system (6) in the constant-motion cabin (22) of the chainsaw; the energy-saving and emission-reduction clean energy electric chainsaw is composed of the constant-motion cabin (1) and the deceleration control power machine (2) , Engine (3), generator (4), super-capacity battery (5) and fan (21).

[0035] The force-by-force and constant-motion cabin (1) consists of the inner sleeve of the constant-movement power unit (7), the front plate of the constant-movement body shell (8), the flange (9), the rear cover of the constant-motion body shell (10), and the constant-movement body Connecting shaft (11), high temperature resistant type axial rare earth strong magnet (12), gradual magnetic power and multi-stage power source device discs (13)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com