Foaming die with dermatoglyph on surface

A foaming mold and skin texture technology, applied in the field of foaming molds with skin texture on the surface, can solve the problems of high technical requirements, increased manufacturing cost, high product scrap rate, and achieve beautiful appearance, low manufacturing cost and uniform pattern of products. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

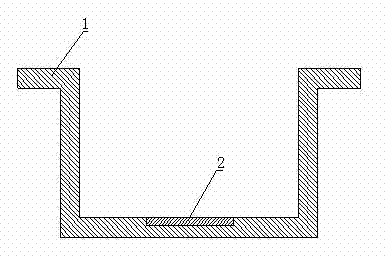

[0007] Such as figure 1 As shown, the mold in the present invention is an aluminum mold 1. According to requirements, the profile of the aluminum mold 1 is divided into a leather-grained area and a non-skinned area. A copper block 2 is inlaid in the leather-grained area of the aluminum mold 1. The copper block 2 and the Aluminum mold 1 interference fit.

[0008] Working principle: Directly inlay copper blocks in the leather pattern area of the aluminum mold, using the difference in heat conduction between the copper block and the aluminum mold, the degree of curing is different, so that the surface of the product forms different patterns, which is compared with the leather pattern formed by acid corrosion , low manufacturing cost, easy to realize, high pattern uniformity, and beautiful appearance of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com