Mold injection molding method used for processing special plastic materials

An injection molding and injection mold technology, which is applied in the field of mold injection molding for processing special plastic materials, can solve the problems of long processing cycle, low efficiency and high cost, and achieve the effects of high dimensional accuracy of products, reduction of technological processes, and improvement of production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

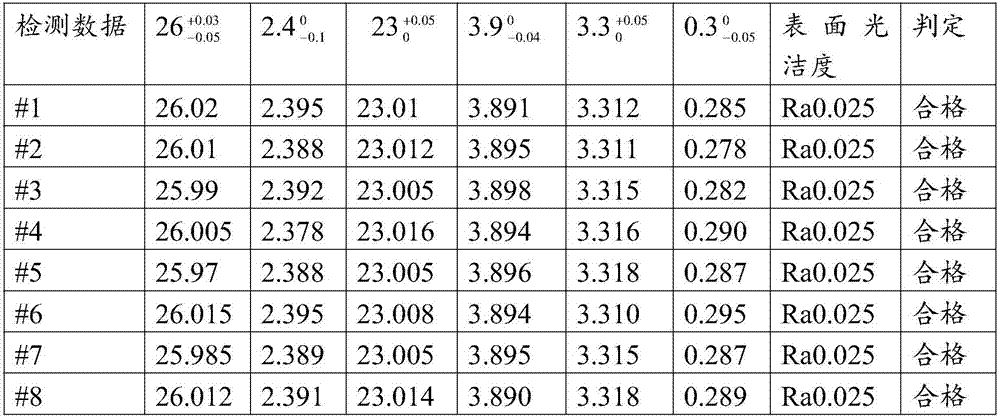

Embodiment 1

[0026] The preprocessed product in this embodiment is an insulating strip.

[0027] A mold injection molding method for processing special plastic materials, comprising the following steps:

[0028] a), according to the structure and size of the insulating strip, make an injection mold for forming the product;

[0029] b), put the special plastic raw material into the baking machine, and bake it at a certain temperature for a period of time to remove the moisture in the special plastic raw material; in this embodiment, the internal temperature of the baking machine is controlled at 200 ° C, and the baking time for 4 hours;

[0030] c) Since the heating temperature of the high-temperature heating ring in a conventional injection molding machine is generally 270-300°C, while the heating temperature of a ceramic heating ring is 450-500°C, the special plastic raw material can only be completely dissolved at 360-380°C; The molding crystallization can only meet the requirements of...

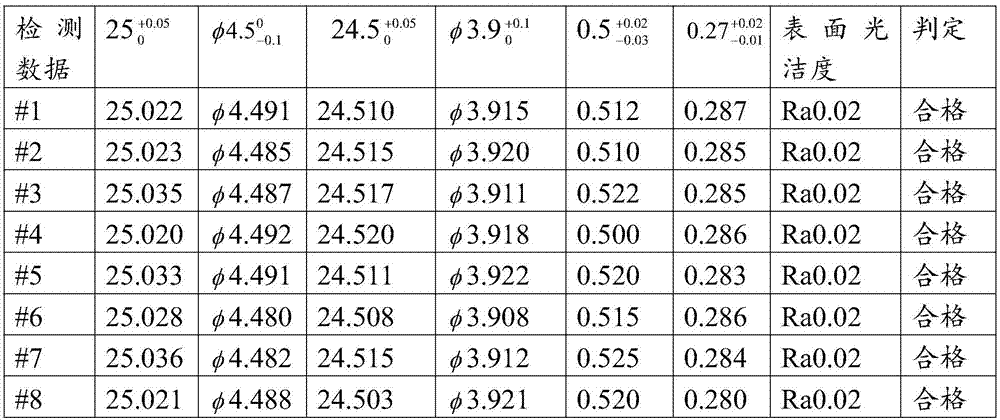

Embodiment 2

[0041] The preprocessed product in this embodiment is an insulating tube.

[0042] A mold injection molding method for processing special plastic materials, comprising the following steps:

[0043] a), according to the structure and size of the insulating tube, make an injection mold for forming the product;

[0044] b), put the special plastic raw material into the baking machine, and bake it at a certain temperature for a period of time to remove the moisture in the special plastic raw material; in this embodiment, the internal temperature of the baking machine is controlled at 180°C, and the baking time for 4 hours;

[0045] c) Since the heating temperature of the high-temperature heating ring in a conventional injection molding machine is generally 270-300°C, while the heating temperature of a ceramic heating ring is 450-500°C, the special plastic raw material can only be completely dissolved at 360-380°C; The molding crystallization can only meet the requirements of use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com