Automatic sealing device with code-spraying and printing mechanism

A printing mechanism and coding technology, used in typewriters, printing, stamping and other directions, can solve the problems of single stamping function, unable to meet the personalized needs of customers, and the specific information of stamping cannot be traced, so as to meet the personalized needs, Has the effect of traceability and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

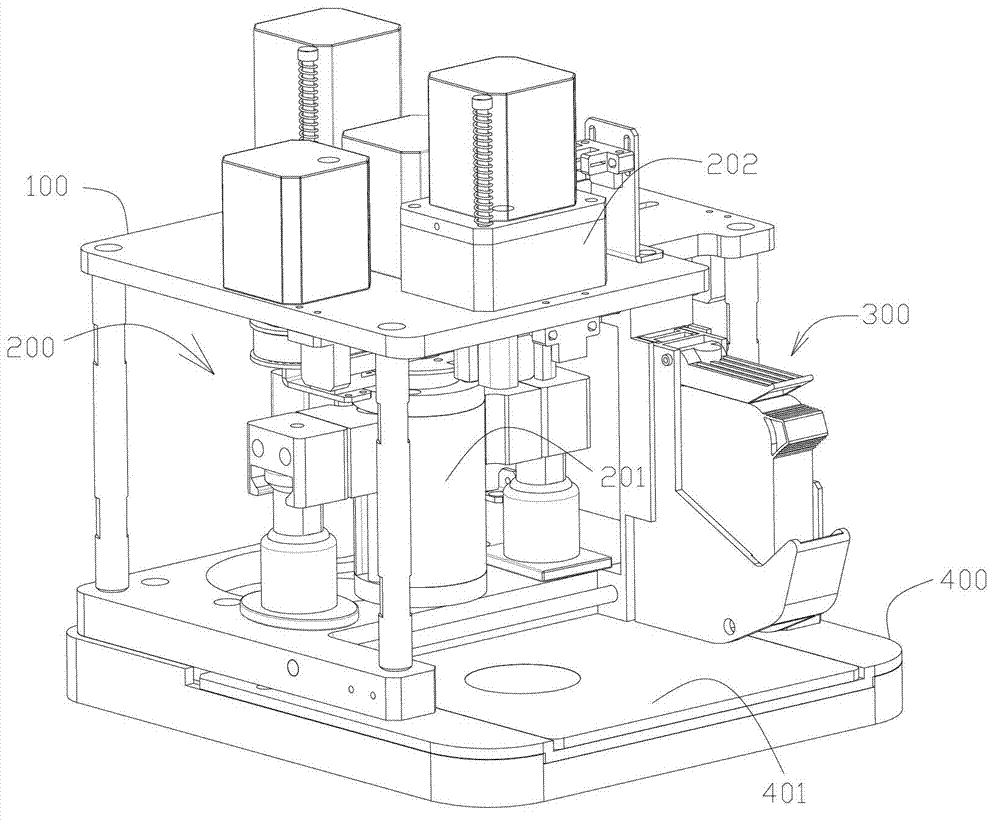

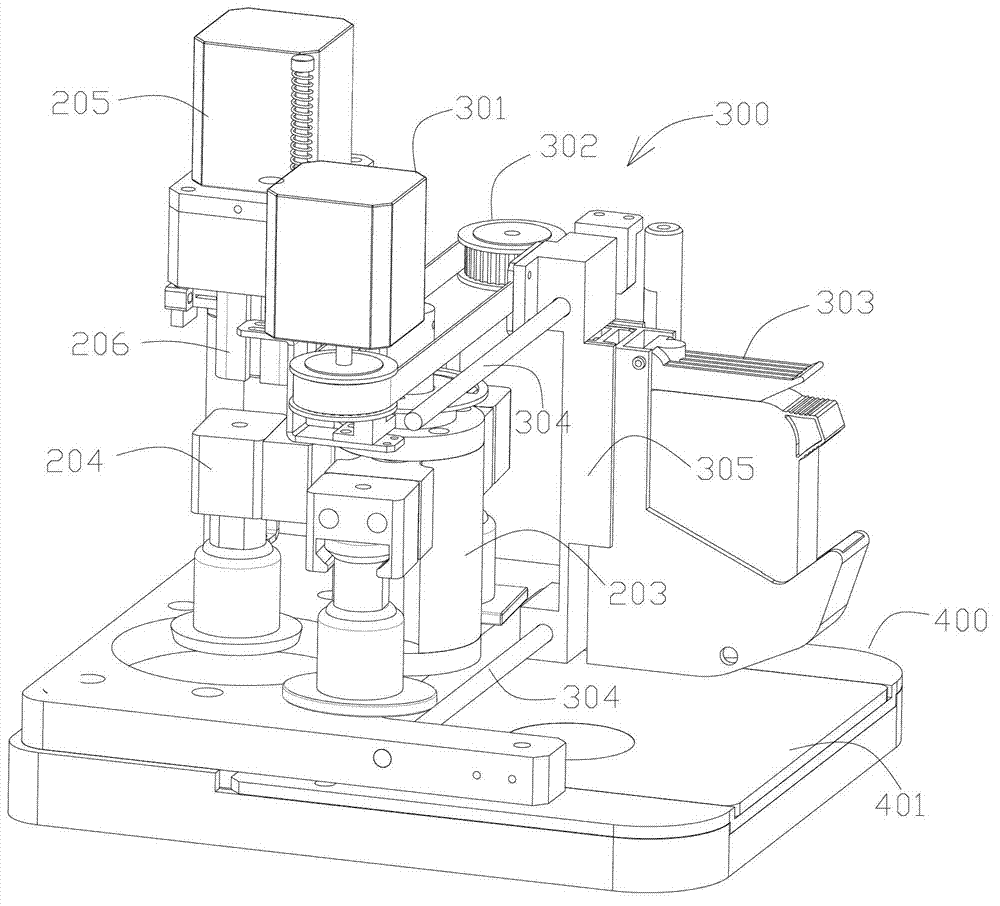

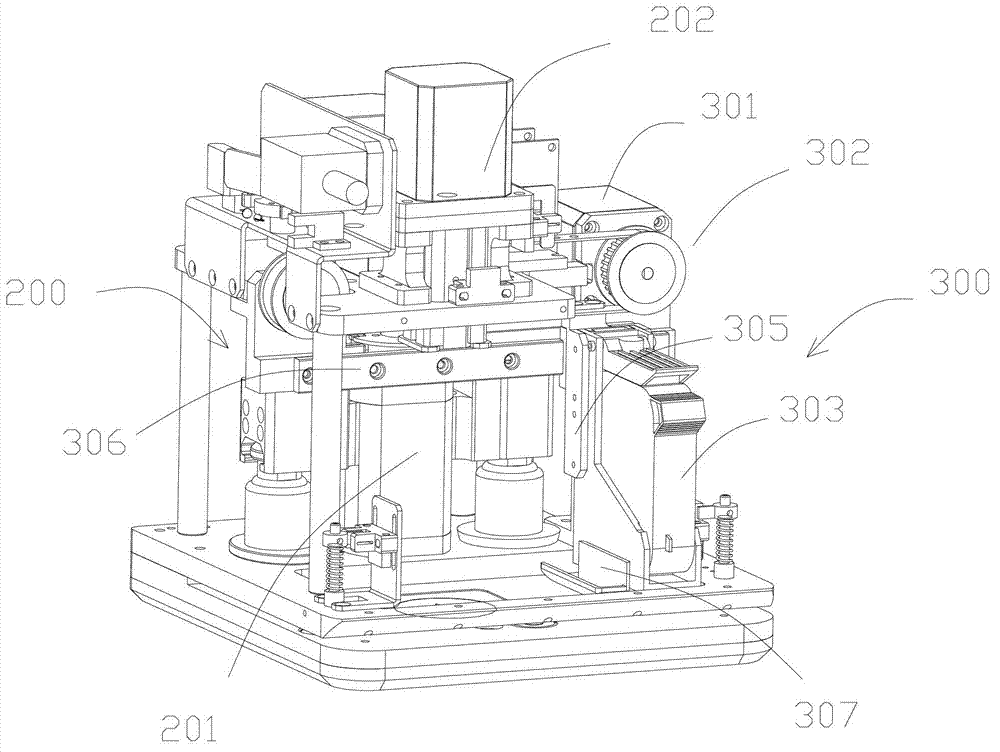

[0023] Such as figure 1 As shown, in the first embodiment of the present invention, the automatic stamping device with a code printing mechanism includes a support frame 100, an automatic stamping mechanism 200 arranged in the support frame 100, and a A coding printing mechanism 300 capable of translational movement. The automatic stamping mechanism 200 further includes a stamp rotating mechanism 201 and a stamping mechanism 202 arranged on the support frame 100 and used to push the stamp downward for stamping. When in use, the stamp rotation mechanism 201 rotates the stamp to a predetermined position, the stamp affixing mechanism 202 pushes the stamp down to the limit position to complete the stamp affixing, and the inkjet printing mechanism 300 translates to the position with the stamp to complete the inkjet and returns to the initial position . The code printing mechanism 300 can spray information such as the date, stamper or even anti-counterfeiting mark on the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com