RFID technology based concrete quality monitoring system and working method thereof

A technology of quality monitoring and working methods, which is applied in the field of concrete quality monitoring system based on RFID technology, can solve the problems of large cost, finished product management, loose transportation and construction, and inability to monitor concrete quality in real time, so as to achieve easy remote access, data Fast processing speed and the effect of ensuring the quality of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

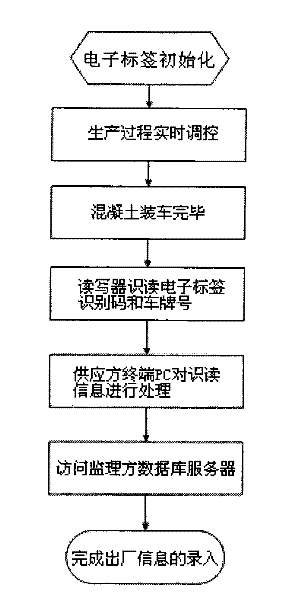

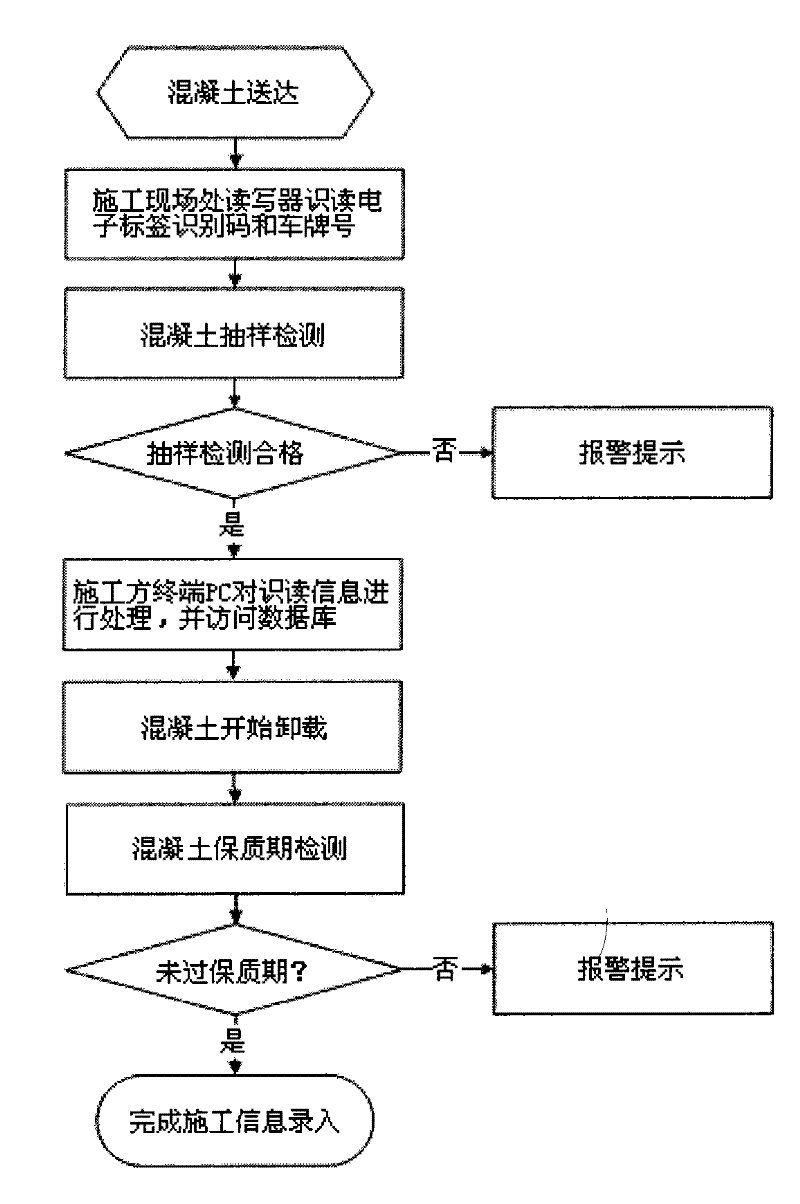

[0030] The invention applies the RFID technology combined with the Internet of Things technology to concrete quality monitoring, and realizes the intelligent monitoring of the quality in the process of concrete production, transportation, construction and maintenance. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

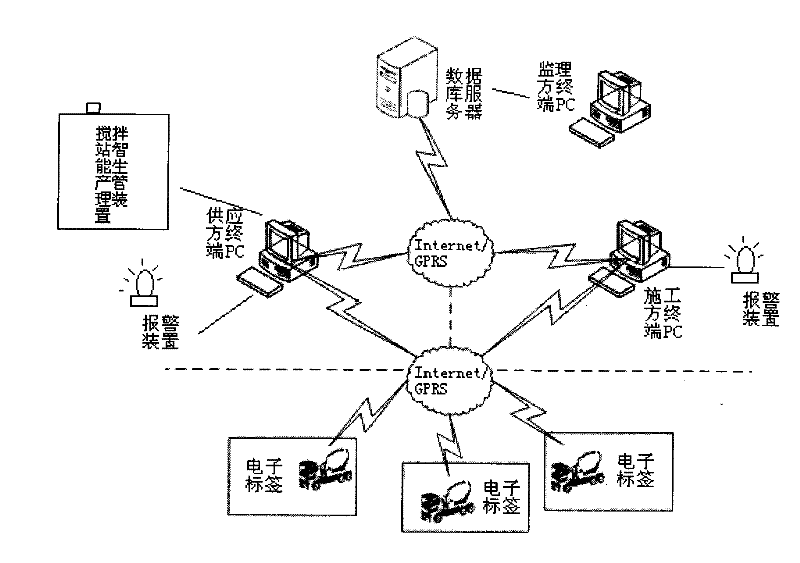

[0031] like figure 1 Shown is a schematic diagram of the concrete quality monitoring system based on RFID technology of the present invention. A uniquely identifiable RFID electronic tag is fixed on the body of each transport vehicle. Both the supplier and the construction party are equipped with RFID readers. It is located at the vehicle exit, and the RFID reader of the construction party is located at the construction site. The RFID reader completes the reading of the RFID electronic tag, and uploads the reading information to the respective terminal PCs, and the terminal PCs encode and impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com