Elevator safety performance parameter measuring device and method and application

A technology of safety performance parameter and measuring device, applied in the field of elevator safety performance parameter measuring device, can solve the problems of offset of elevator weighing device, large artificial deviation of measuring method, no data support, etc. The process is simple and fast, and the data is accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A method for measuring elevator safety performance parameters, using an elevator safety performance parameter measuring device to measure the balance coefficient of the elevator, comprising the steps of:

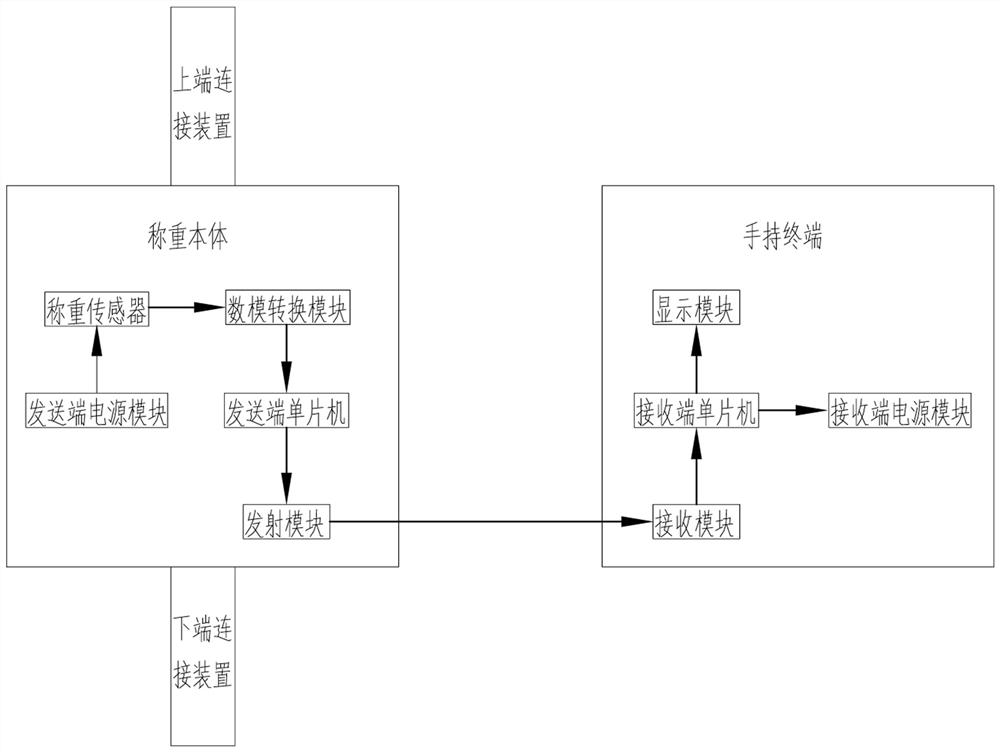

[0078] The elevator car 1 is empty, and the inspection operation makes the elevator car 1 and the counterweight 2 reach the same height. The traction rope on the side of the car between the upper connecting device and the lower connecting device is loose. At this time, the load cell measures the weight of car 1, and the load cell transmits the measured data to the digital-to-analog conversion module. The digital-to-analog conversion module The data is converted into a digital signal and transmitted to the MCU at the sending end, encoded by the MCU at the sending end, transmitted by the transmitting module, received by the receiving module on the handheld terminal, processed by the MCU at the receiving end, displayed by the display module, and recorded. Value, recorded...

Embodiment 2

[0090] A method for measuring elevator parameters, using an elevator safety performance parameter measuring device to measure the traction capacity of the elevator, comprising the following steps:

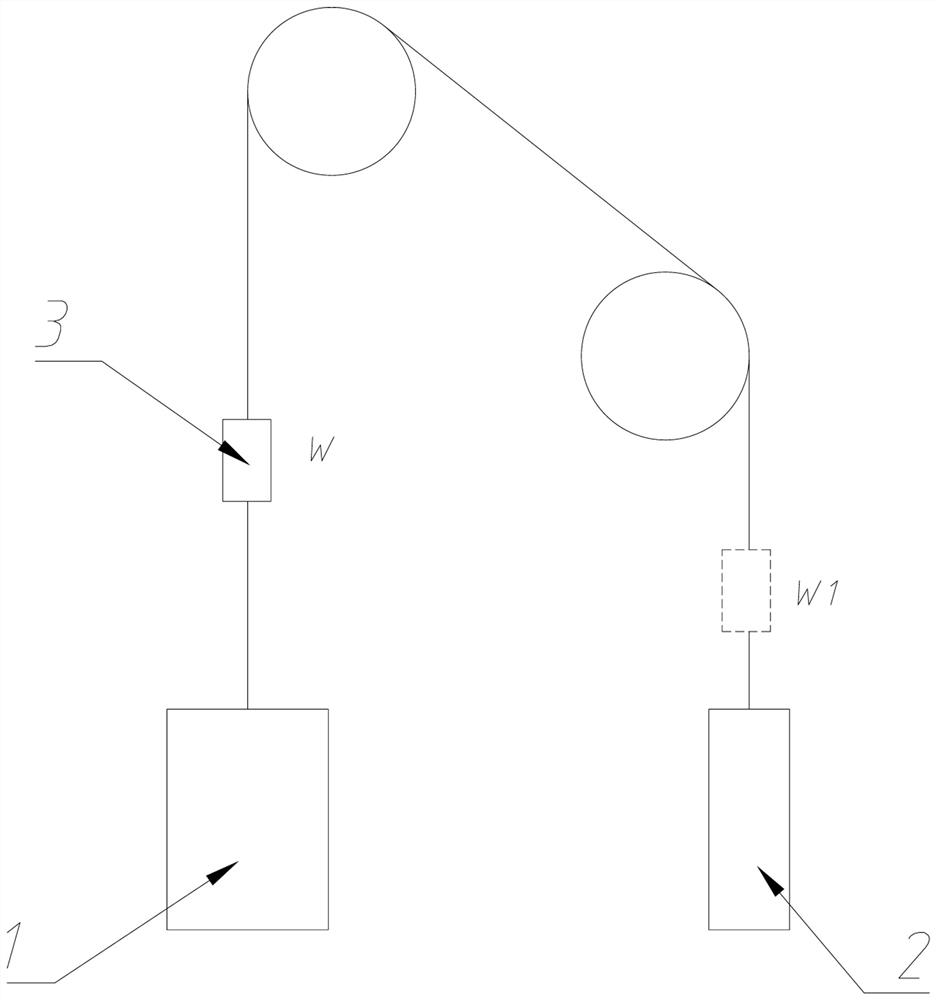

[0091] Elevator car 1 is empty, make the elevator maintenance run to the top floor, and ensure that the distance between the bottom of the counterweight 2 and the floor of the elevator pit is 1-1.8m, connect the upper end connecting device with the bottom beam at the bottom of the counterweight 2, and connect the lower end The device is connected with the ground anchor preset on the floor of the elevator pit under the counterweight 2 through the pulling device, and the pulling device acts to shorten the distance between the counterweight 2 and the elevator pit. The pulling device includes a hydraulic pull rod and a hydraulic pump. The lower connection device is connected to the ground anchor preset on the floor of the elevator pit below the counterweight 2 through a hydraulic tie ro...

Embodiment 3

[0095] A method for measuring elevator safety performance parameters, using an elevator safety performance parameter measuring device to measure the load capacity of the elevator, comprising the steps of:

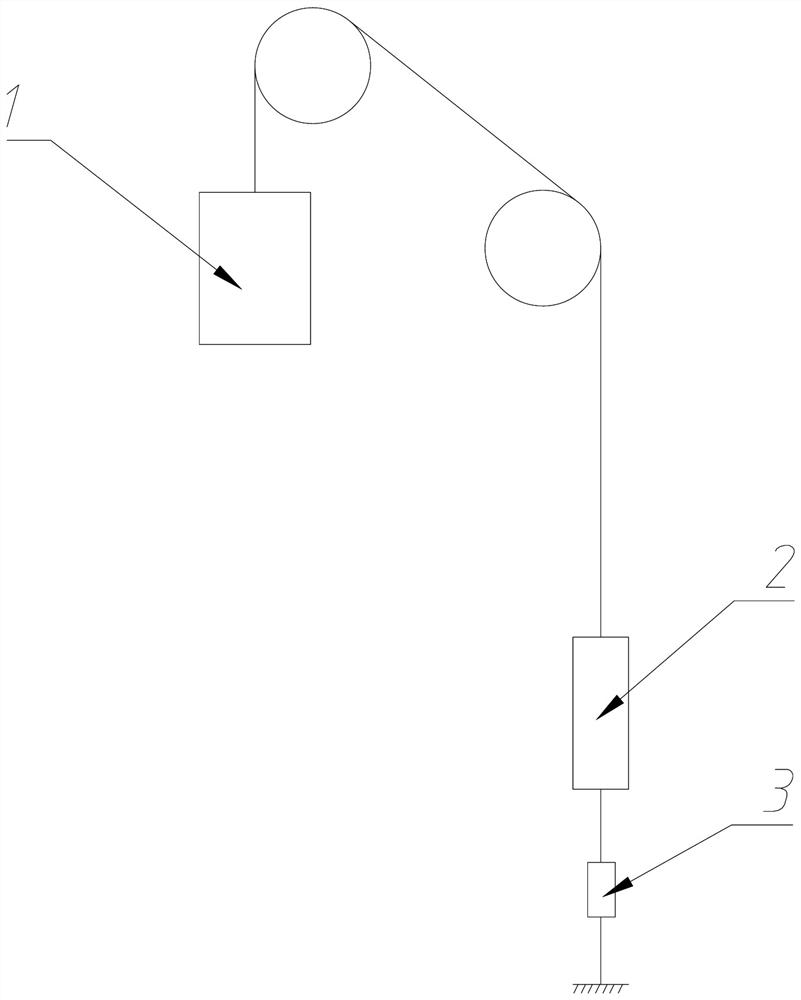

[0096] Elevator car 1 is empty, so that the elevator runs to the bottom floor for maintenance, and ensure that the distance between the bottom beam on car 1 and the floor of the elevator pit is 1-1.8m, and the upper end connecting device is passed through the preset position of the car through rigging. 1. After the pulley at the lower part of the bottom beam, connect the other end of the sling to the ground anchor on the floor of the elevator pit, and connect the lower end connecting device to the ground anchor preset on the ground of the elevator pit through a pulling device. The pulling device operates, and the car The distance between compartment 1 and the elevator pit is shortened. The pulling device includes a hydraulic pull rod and a hydraulic pump, that is, the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com