Comprehensive operation vehicle of railway contact system

A catenary and operating vehicle technology, which is applied to railway car body components, transport passenger cars, transmission devices with reciprocating piston internal combustion engines, etc., can solve problems such as unsafe factors, high energy consumption, and difficulty in adapting to the needs of railways, etc. Achieve the effects of improving economy, reducing energy consumption, and large operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

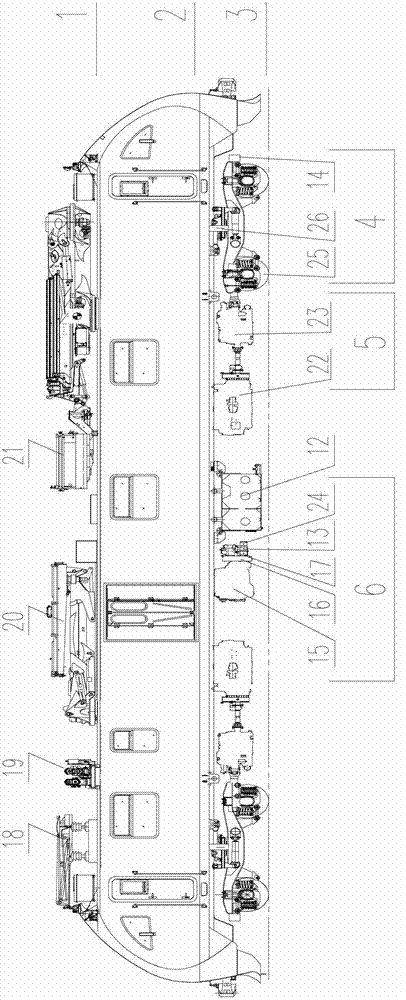

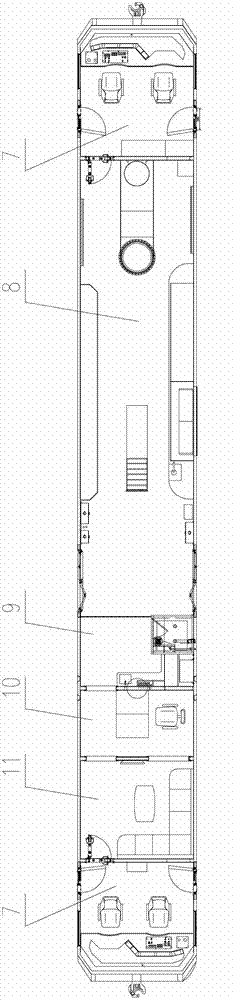

[0016] Attached below figure 1 , 2 An embodiment of the present invention is described.

[0017] The railway catenary comprehensive operation vehicle includes an operation system 1, a car body 2 and a power transmission system 3. The operation system 1 is composed of a catenary detection device 18, a wire lifting device 19, an operation platform 20 and an aerial work bucket 21, and It is arranged on the upper part of the vehicle body 2 , and the power transmission system 3 includes a power transmission device 5 and a working power system 6 , both of which are arranged on the lower part of the vehicle body 2 . The car body 2 is provided with a front and rear driver's cab 7, a working room 8, a testing room 10, a rest area 11 and a living area 9, providing perfect living facilities for the staff.

[0018] The above-mentioned power transmission device 5 includes an engine 22 and a hydraulic transmission box 23, the output end of the engine 22 is connected to the input end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com