Novel adjustable window bucket for ship

A new type of marine technology, applied in the direction of porthole doors, ship parts, ship construction, etc., can solve the problem of unequal bottom frame, achieve high aesthetics, high product adaptability, and shorten the installation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

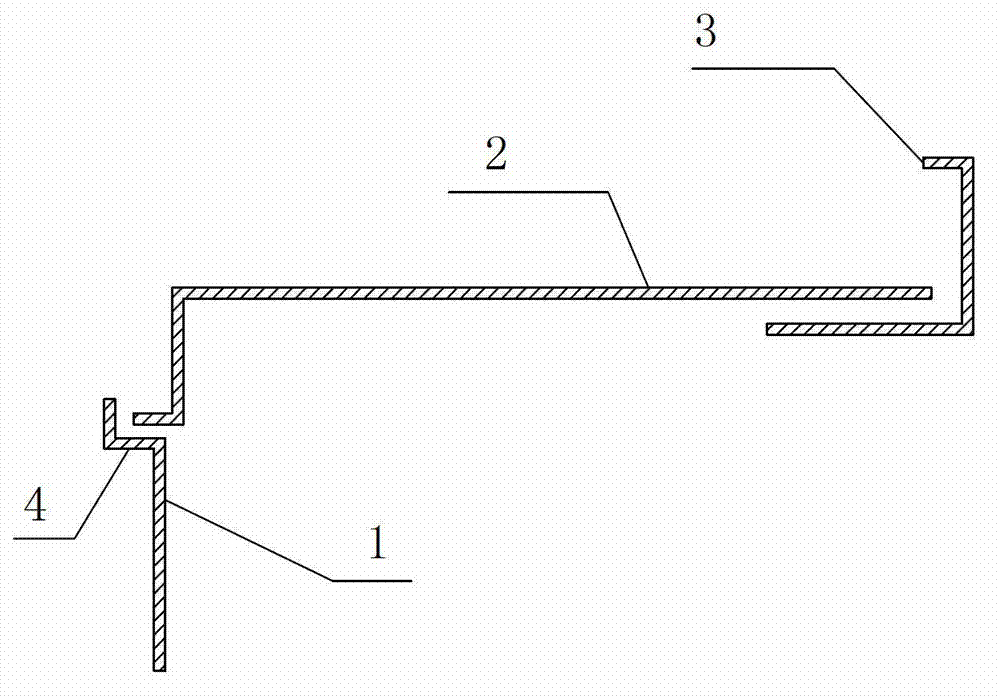

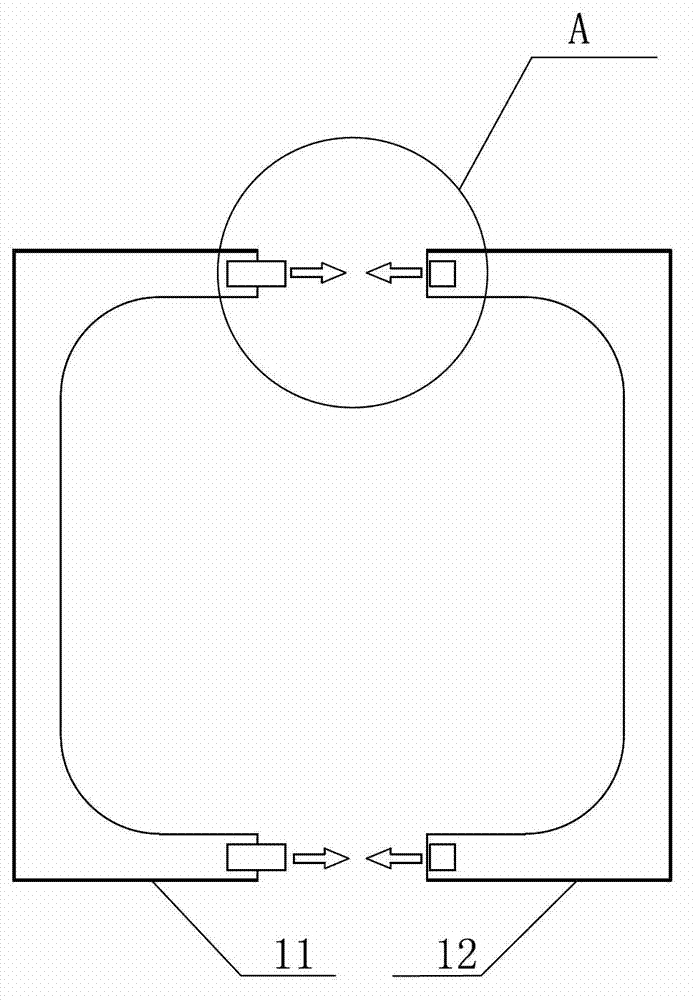

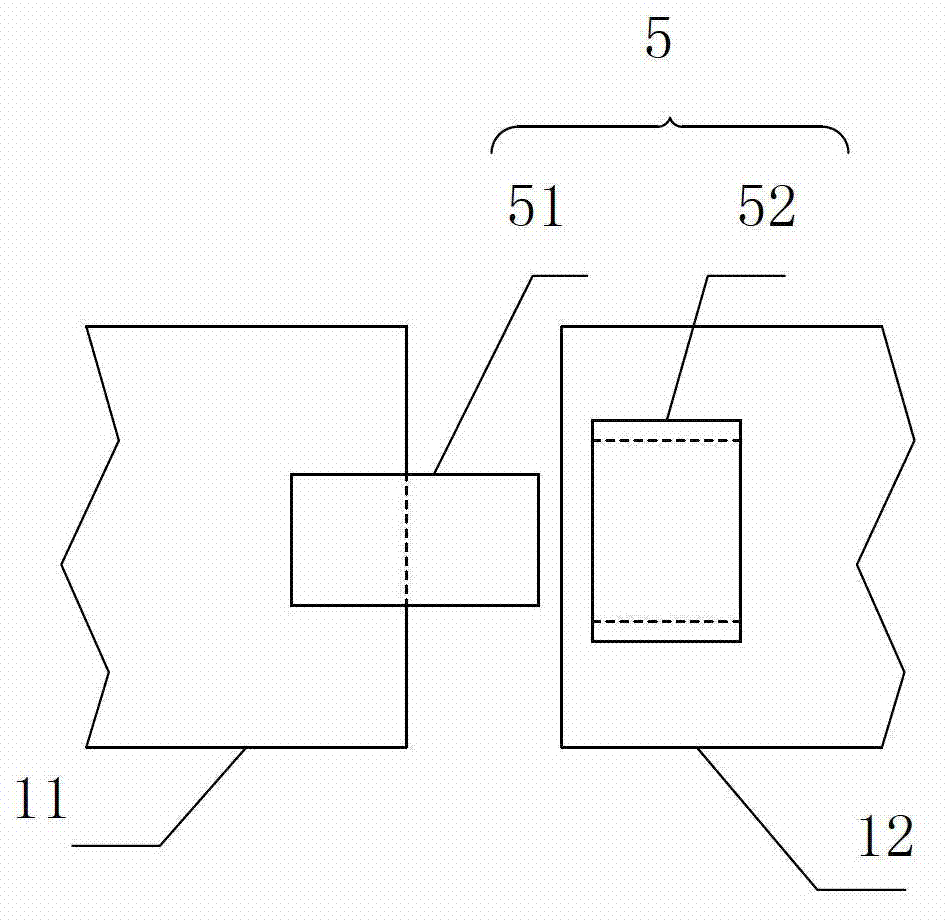

[0019] refer to figure 1 , a structural schematic diagram of the present invention, from which we can see that the present invention—a new type of adjustable window bucket for ships, consists of three parts: the bottom frame 1, the middle frame 2 and the upper pressure frame 3, and combined with figure 2 , the front view of the bottom frame structure of the present invention, it can be found that the bottom frame 1 is composed of two half-frames 11, 12 butted with each other, and a supporting foot 4 and a bottom frame inserting plate 5 are designed on it. The design of the support foot 4 can make the bottom frame 1 and the middle frame 2 firmly connected together. At the same time, the support foot 4 and the metal window welding foot form two fulcrums. The bottom frame 1 can well avoid welding, thus ensuring The level can eliminate the problem that the welding foot of the metal window affects the installation level of the bottom frame 1.

[0020] image 3 yes figure 2 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com