Thrust device capable of balancing reactive torque

A thrust device and anti-torque technology, applied in the field of aerodynamics, can solve problems such as accidents, high accident rate, unsuitability for multi-flight mode rotary wing aircraft, etc., achieve high aerodynamic efficiency and increase flight speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is specifically described below in conjunction with embodiment:

[0020] This embodiment is an anti-torque thrust device used on a rotary wing aircraft, and the whole device is installed at the tail of the rotary wing aircraft.

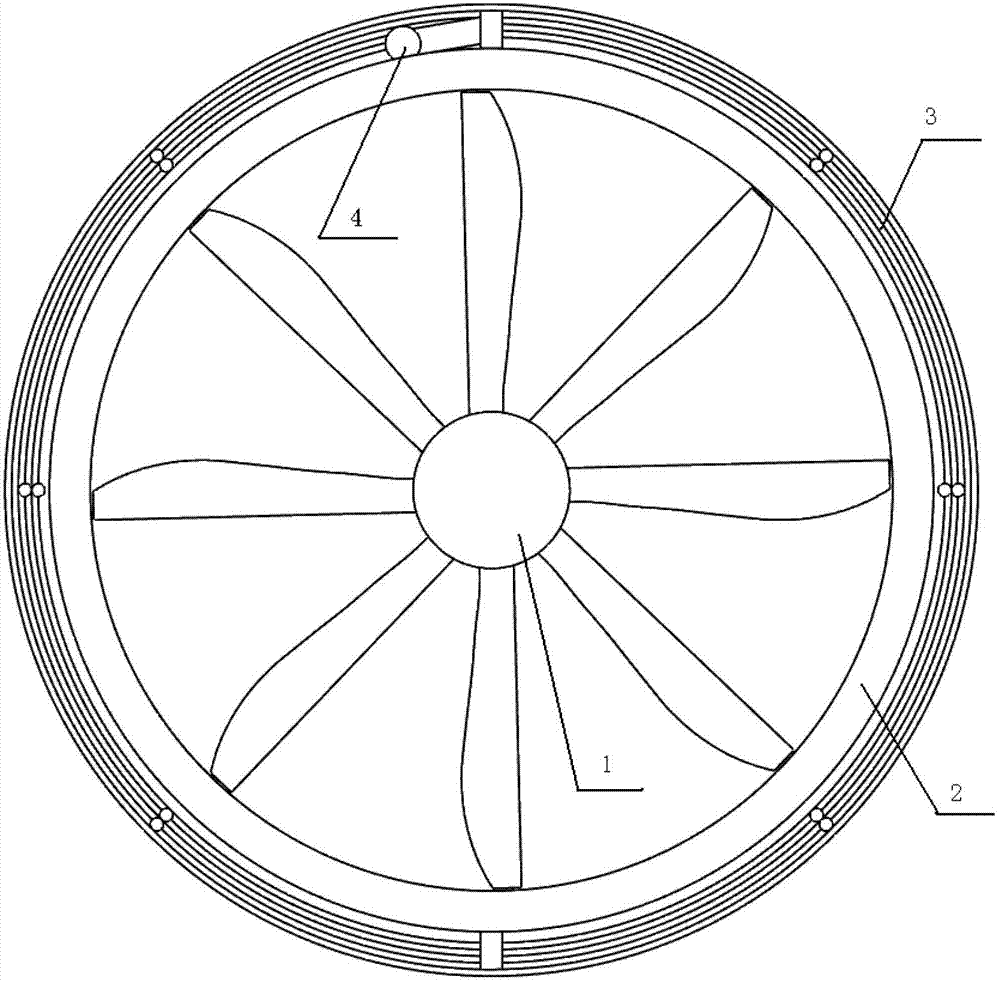

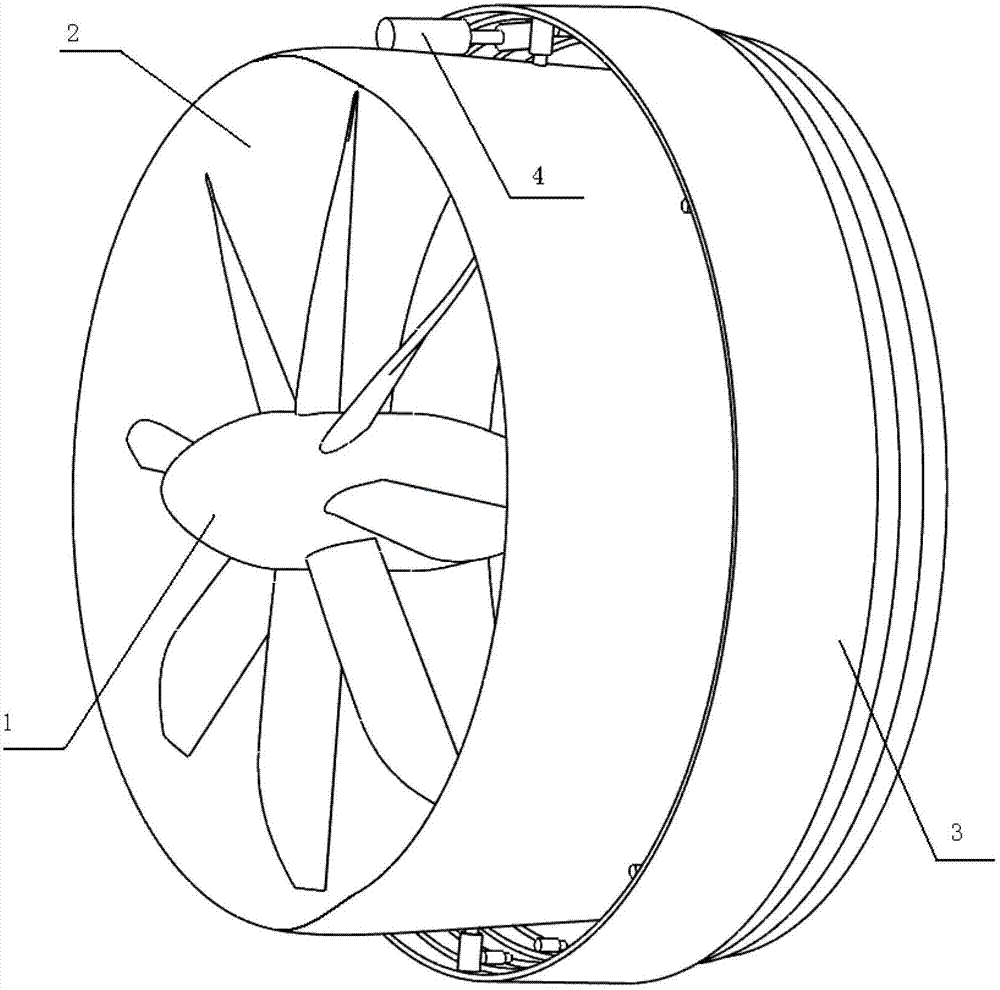

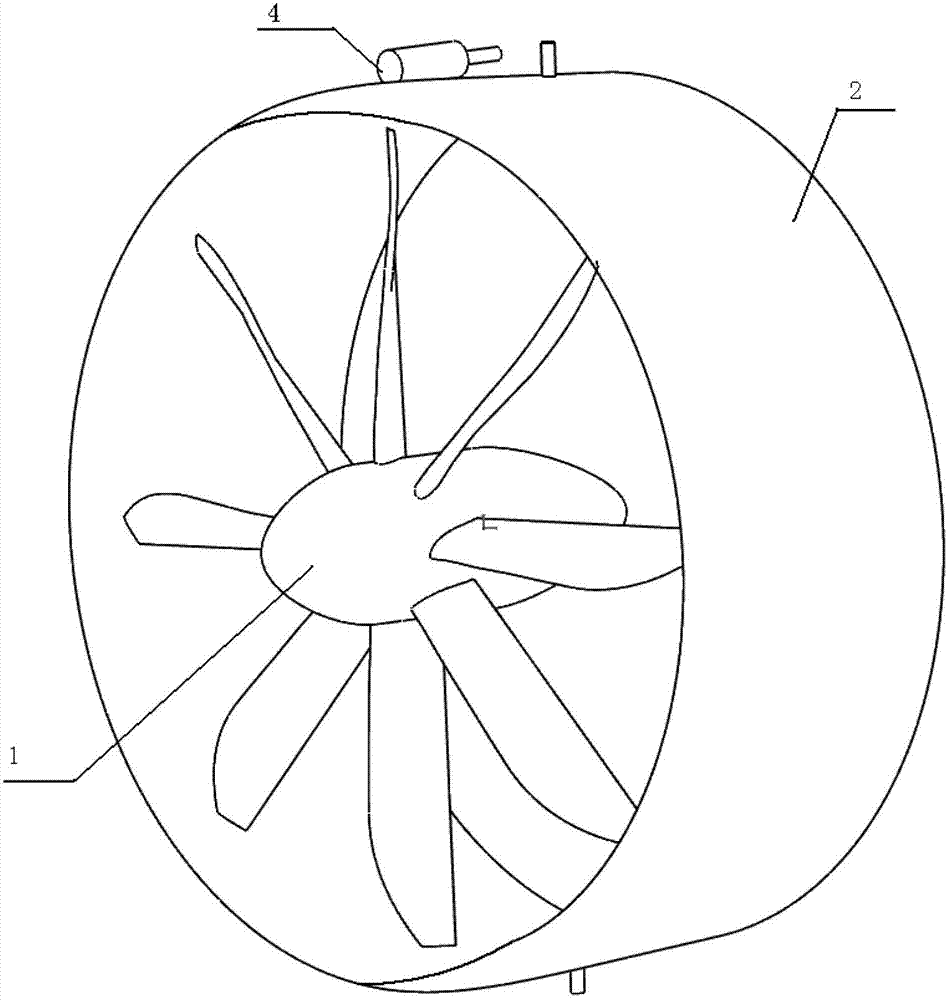

[0021] Refer to attached figure 1 And attached figure 2 , the thrust device capable of balancing the reaction torque in this embodiment includes a ducted propeller and a retractable guide cylinder 3 for changing the thrust direction.

[0022] The ducted propeller is divided into a propeller 1 that rotates to generate airflow and a duct 2 that surrounds the propeller. Two rotating shafts with a diameter of 30 mm are fixed and welded symmetrically on the outer wall of the duct shell, and the center lines of the two shafts coincide and pass through the central axis of the duct vertically. When the whole device was installed on the tail of the rotary wing aircraft, the center line of the two rotating shafts was parallel to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com