Liquid crystal display panel conveying system and automatic crane thereof

A transmission system and liquid crystal panel technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as inability to detect in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It is particularly pointed out that the following embodiments are only used to illustrate the present invention, but do not limit the scope of the present invention. All other embodiments obtained by those skilled in the art without creative work belong to the protection of the present invention. scope.

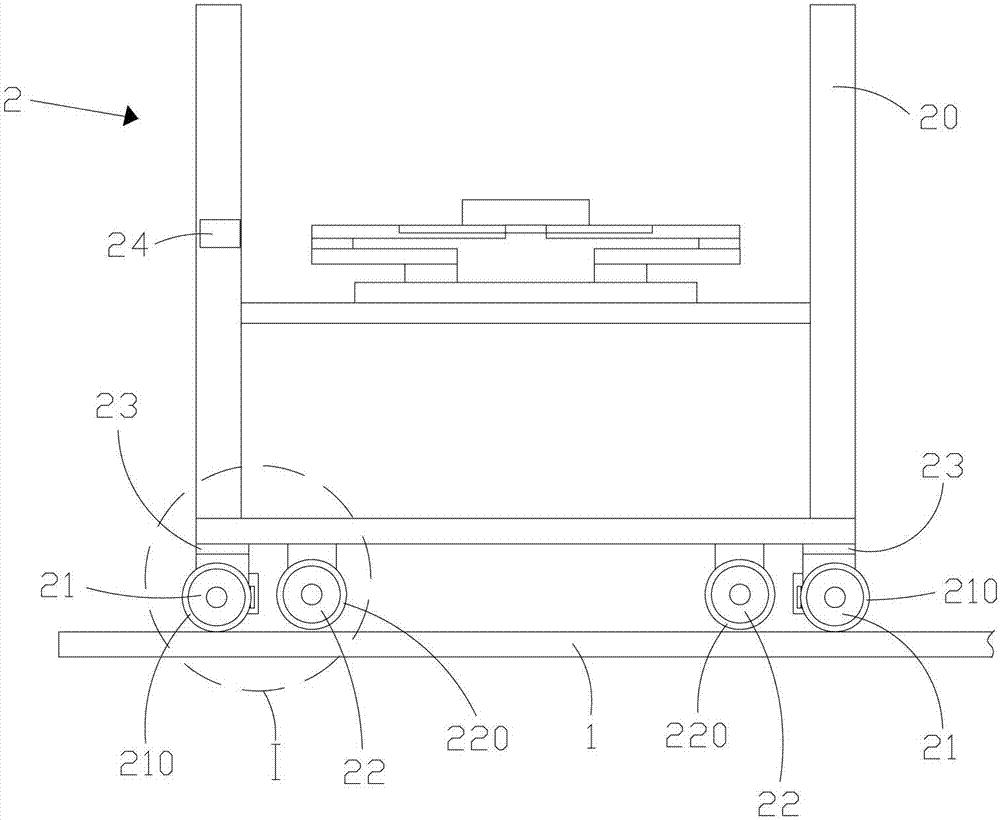

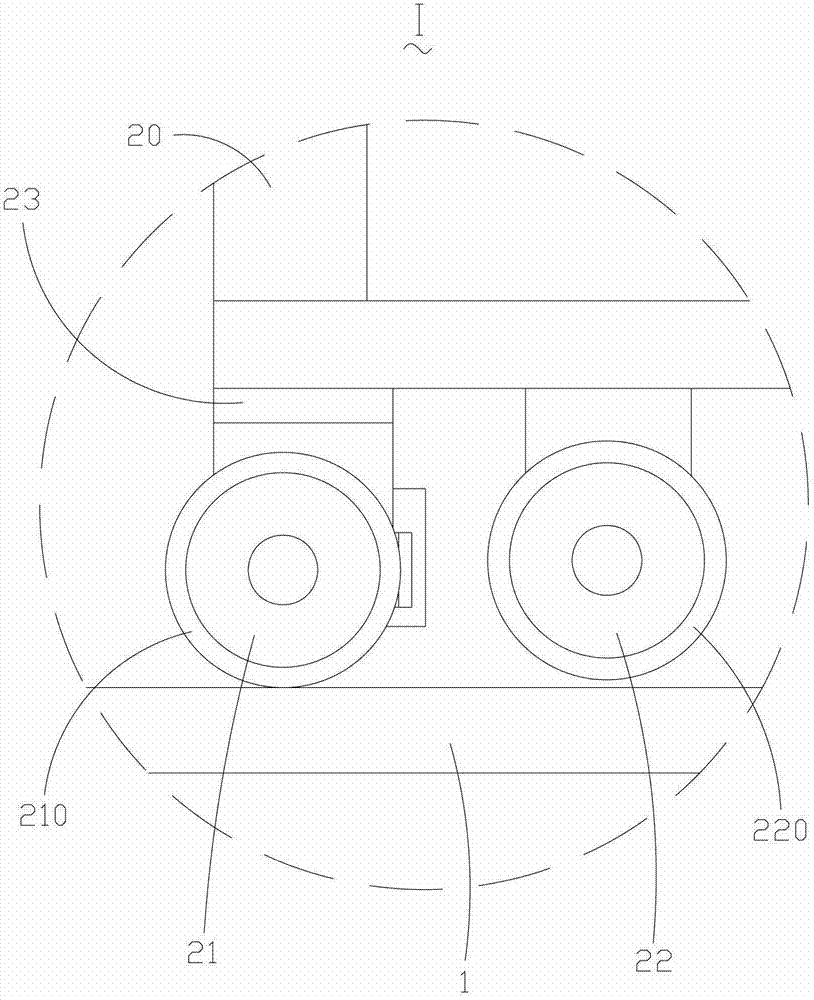

[0022] Please also refer to figure 1 with figure 2 , in an embodiment of the liquid crystal panel transport system of the present invention, the liquid crystal panel transport system includes a guide rail 1 and a transport device 2 . Wherein, the guide rail 1 may be integrally formed, or may be a plurality of guide rails that are smoothly transitionally connected to each other. Here, "smooth transition connection" means that the connection between two guide rails is smooth, and in this embodiment, it can be realized by welding, grinding and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com