Online coating weight monitoring method

A technology of coating amount and coating, which is applied in the field of laser holographic material processing, can solve the problems of low work efficiency, fluctuation of coating amount, and inability to reflect the coating amount, etc., and achieve the effect of high work efficiency and reduced scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

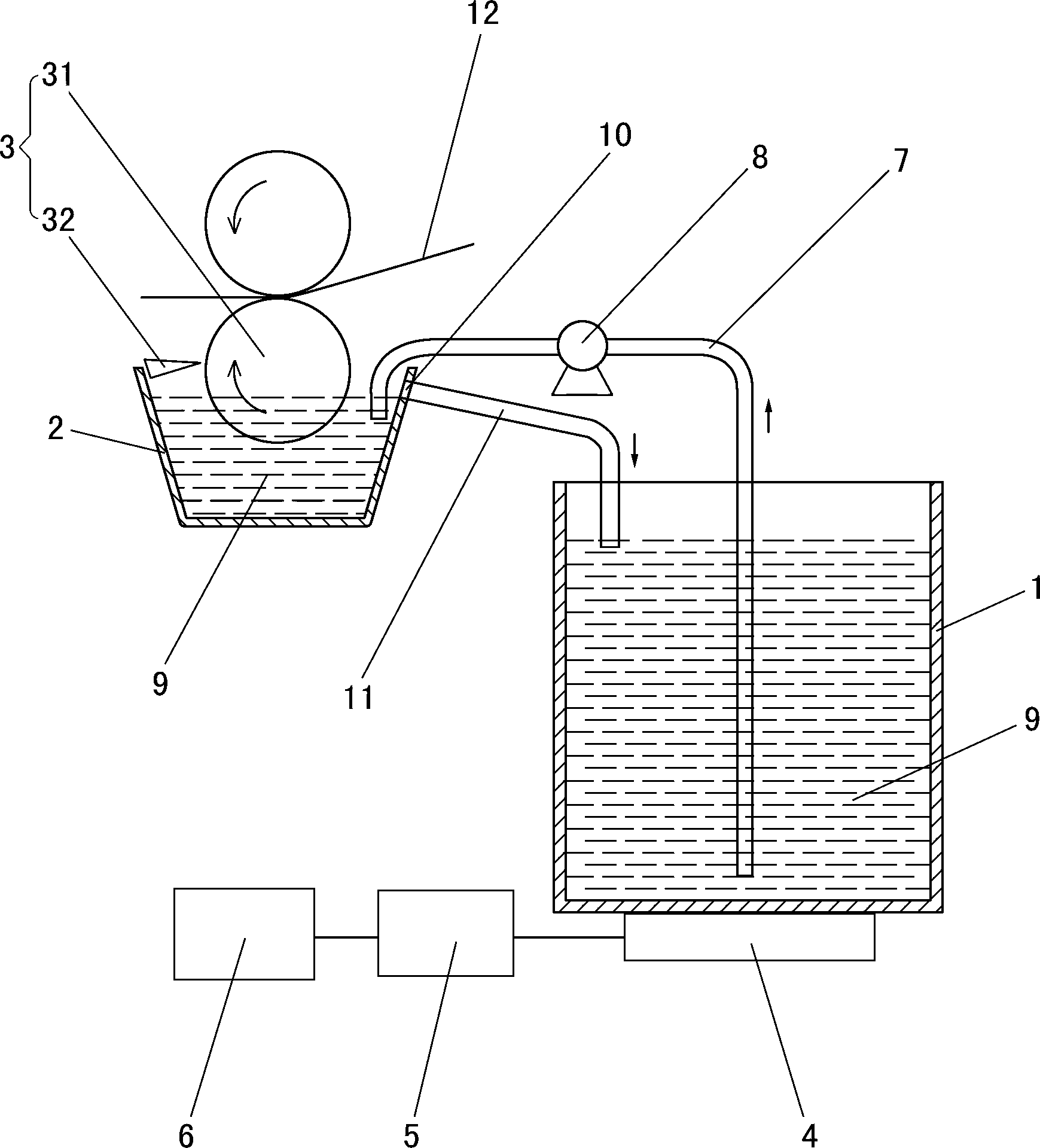

[0015] refer to figure 1 , in the manufacturing process of laser holographic materials, the device that completes the coating process on the substrate (such as plastic film) usually includes a paint storage container 1, a material tank 2 and a coating mechanism 3, and the cavity of the paint storage container 1 passes through the supply The feed pipe 7 communicates with the cavity of the feed tank 2 (a pump 8 may be provided on the feed pipe 7, and the paint 9 in the paint storage container 1 is pumped into the feed tank 2 by the pump 8), and the coating mechanism 3 is located in Above the trough 2 (the coating mechanism 3 may include an anilox roller 31 and a scraper 32, and the anilox roller 31 is partially immersed in the paint 9 in the trough 2; other existing coating mechanisms can also be used), a paint storage container 1 The coating 9 in the feed pipe 7 is transported to the material tank 2, and the coating mechanism 3 obtains the coating from the material tank 2 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com