Defect detection system and defect detection method

A defect detection and defect technology, which is applied in the direction of optical test defect/defect, measurement device, material analysis through optical means, etc., can solve problems such as poor performance, and achieve the effect of improving performance and stabilizing product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] As mentioned in the background, the performance of existing systems for wafer surface defect detection is poor.

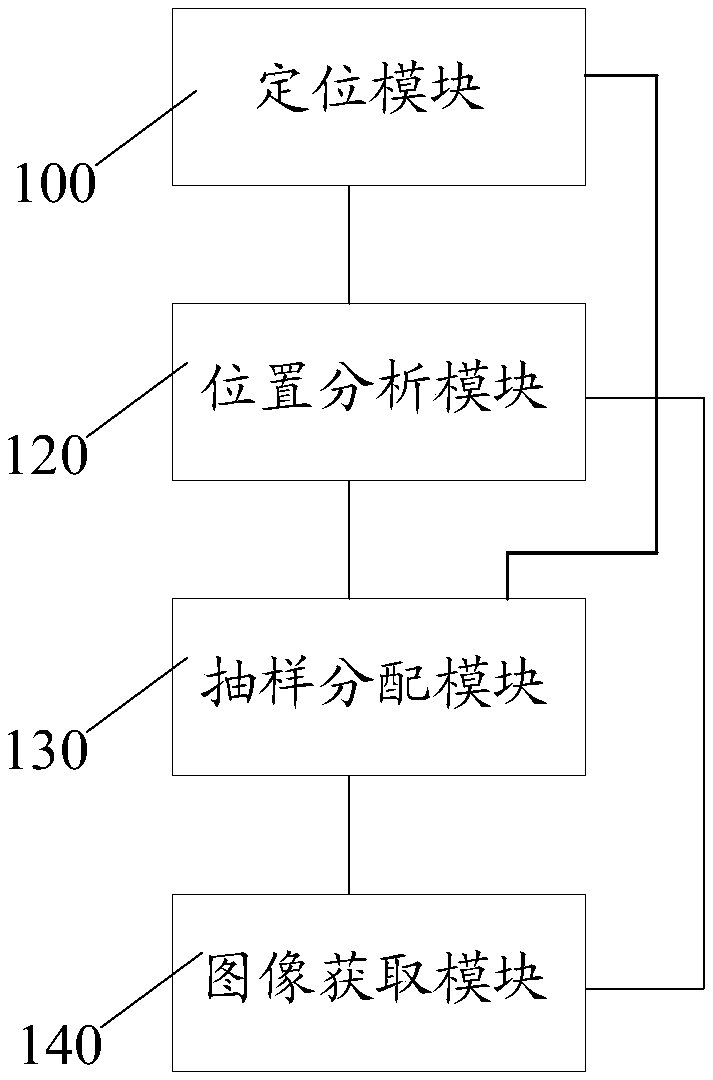

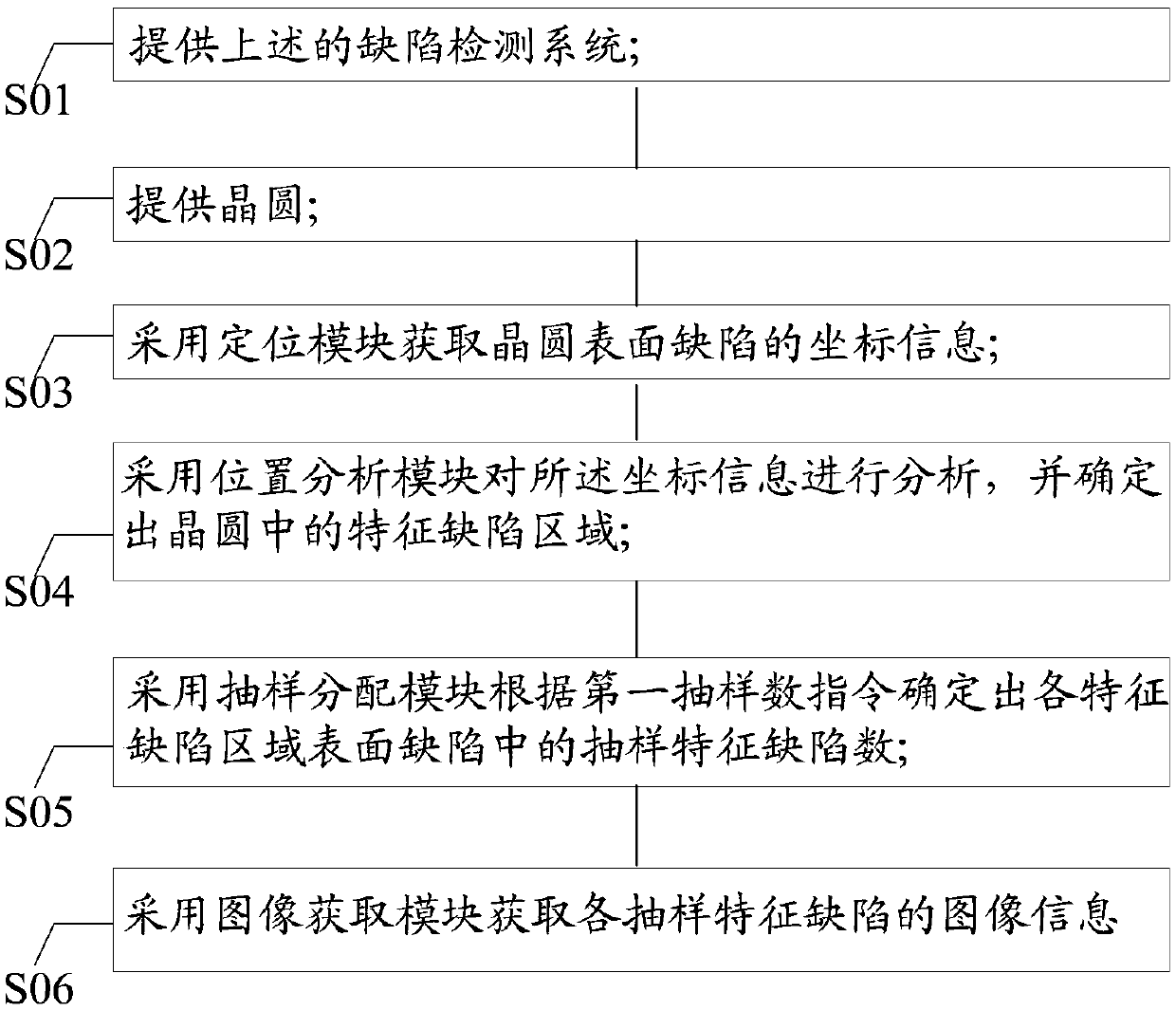

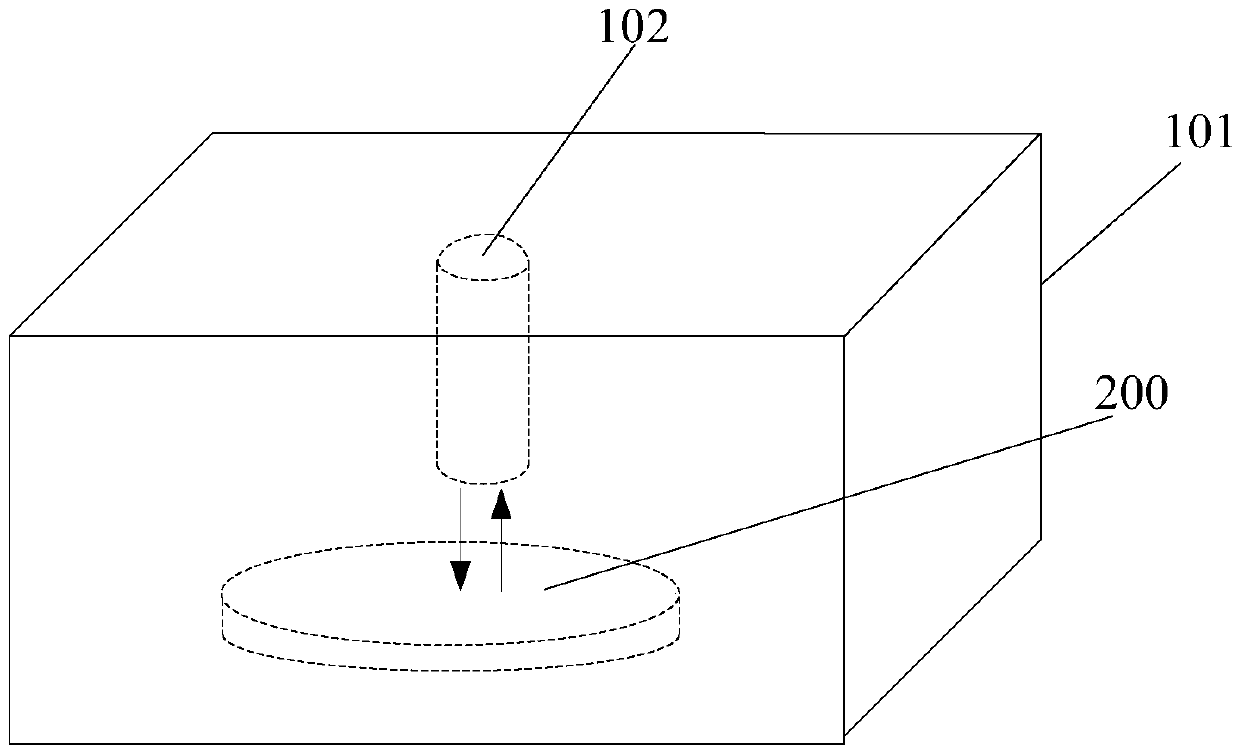

[0024] A defect detection method, comprising: providing a bright-field and dark-field scanning machine; providing an image acquisition module, the image acquisition module including a random sampling module and an image acquisition module; using the bright-field and dark-field scanning machine to obtain the surface defects of the wafer Coordinate information; the random sampling module is used to sample the coordinate information of defect points; the image acquisition module performs image acquisition on the extracted defect points. Then analyze the defect point according to the image information of the defect point.

[0025] When the distribution of defect points in certain areas of the wafer is relatively special, it is necessary to analyze the defect points on the surface of the special area. However, due to the randomness of the defect point sampling b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com