Rubber and plastic waterproof bonding modification asphalt mastic and preparation method of rubber and plastic waterproof bonding modification asphalt mastic

A technology for modifying asphalt and thermoplastic resins, which can be applied to other rubber adhesives, asphalt material adhesives, adhesives, etc., and can solve problems such as insufficient high temperature stability, rutting, and shifting of pavement layers, and achieve good deformation following ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

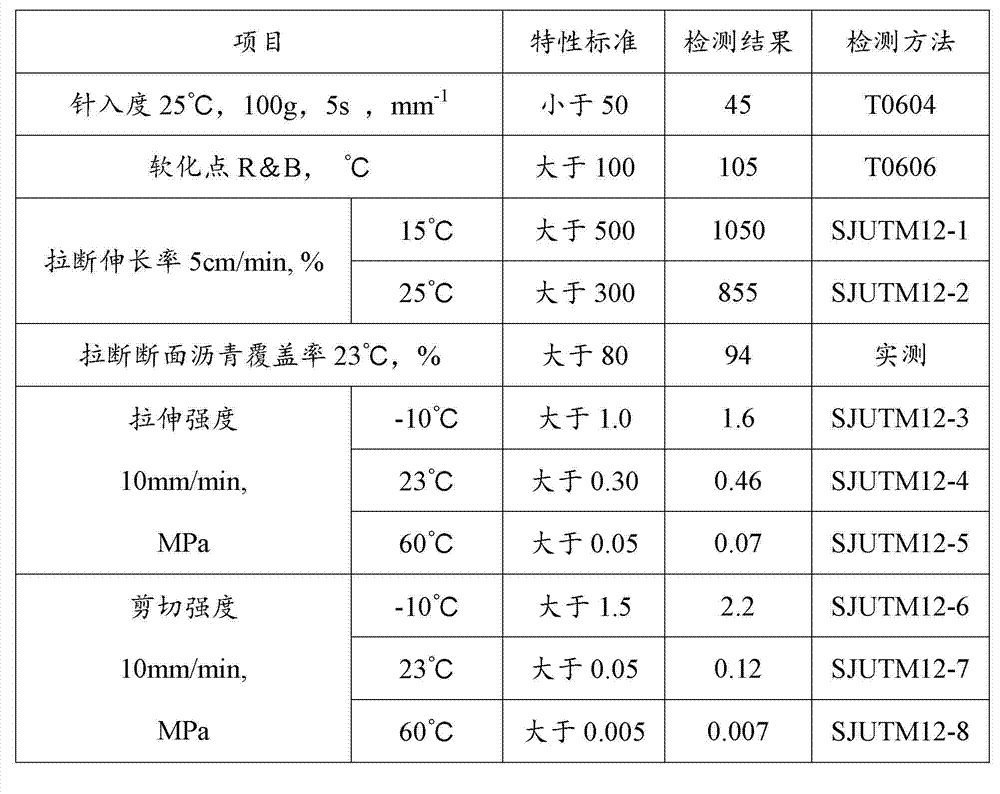

Examples

Embodiment 1

[0026] A rubber-plasticized waterproof bonding modified asphalt rubber, the raw material composition of which is as follows in parts by weight: 10 parts of waste tire rubber powder; 5 parts of thermoplastic resin; 1 part of thermoplastic elastomer; 5 parts of octene-ethylene copolymer; 4 parts of terpene resin; 5 parts of tall oil carboxylic acid polyamine; 3 parts of styrene-butadiene rubber; 20 parts of petroleum asphalt.

[0027] The thermoplastic resin is polyethylene.

[0028] The thermoplastic elastomer is a styrene-butadiene block polymer.

[0029] The specific preparation steps of the rubber-plasticized waterproof adhesive modified asphalt glue are:

[0030] (1) Heat the petroleum asphalt to a fluid state, and add tall oil carboxylic acid polyamine, waste tire rubber powder, thermoplastic resin, thermoplastic elastomer, octene-ethylene copolymer, terpene resin, and styrene-butadiene rubber in proportion;

[0031] (2) Grind the above mixture at 190°C until uniform wit...

Embodiment 2

[0033] A rubber-plasticized waterproof bonding modified asphalt rubber, the raw material composition of which is as follows in parts by weight: 15 parts of waste tire rubber powder; 7 parts of thermoplastic resin; 5 parts of thermoplastic elastomer; 10 parts of octene-ethylene copolymer; 10 parts of terpene resin; 15 parts of tall oil carboxylic acid polyamine; 5 parts of styrene-butadiene rubber; 70 parts of petroleum asphalt.

[0034] The thermoplastic resin is polypropylene.

[0035] The thermoplastic elastomer is a styrene-isoprene block polymer.

[0036] The specific preparation steps of the rubber-plasticized waterproof adhesive modified asphalt glue are:

[0037] (1) Heat the petroleum asphalt to a fluid state, and add tall oil carboxylic acid polyamine, waste tire rubber powder, thermoplastic resin, thermoplastic elastomer, octene-ethylene copolymer, terpene resin, and styrene-butadiene rubber in proportion;

[0038] (2) Grind the above mixture at 200°C until uniform w...

Embodiment 3

[0040] A rubber-plasticized waterproof bonding modified asphalt rubber, the raw material composition of which is as follows in parts by weight: 20 parts of waste tire rubber powder; 10 parts of thermoplastic resin; 2 parts of thermoplastic elastomer; 6 parts of octene-ethylene copolymer; 6 parts of terpene resin; 10 parts of tall oil carboxylic acid polyamine; 4 parts of styrene-butadiene rubber; 45 parts of petroleum asphalt.

[0041] The thermoplastic resin is a mixture of polyethylene and polypropylene, wherein the mass ratio of polyethylene and polypropylene is 1:1.

[0042] The thermoplastic elastomer is a mixture of styrene-butadiene block polymer and styrene-isoprene block polymer, wherein, styrene-butadiene block polymer and styrene-isoprene The mass ratio of pentadiene block polymer is 1:1.

[0043] The specific preparation steps of the rubber-plasticized waterproof adhesive modified asphalt glue are:

[0044] (1) Heat the petroleum asphalt to a fluid state, and add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com