Cast asphalt concrete material and preparation method thereof

A kind of asphalt concrete, pouring technology, applied in the field of road construction materials, can solve the problems of rutting, affecting the driving safety and service life of the pavement, and achieve the effect of excellent high temperature stability and good water tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

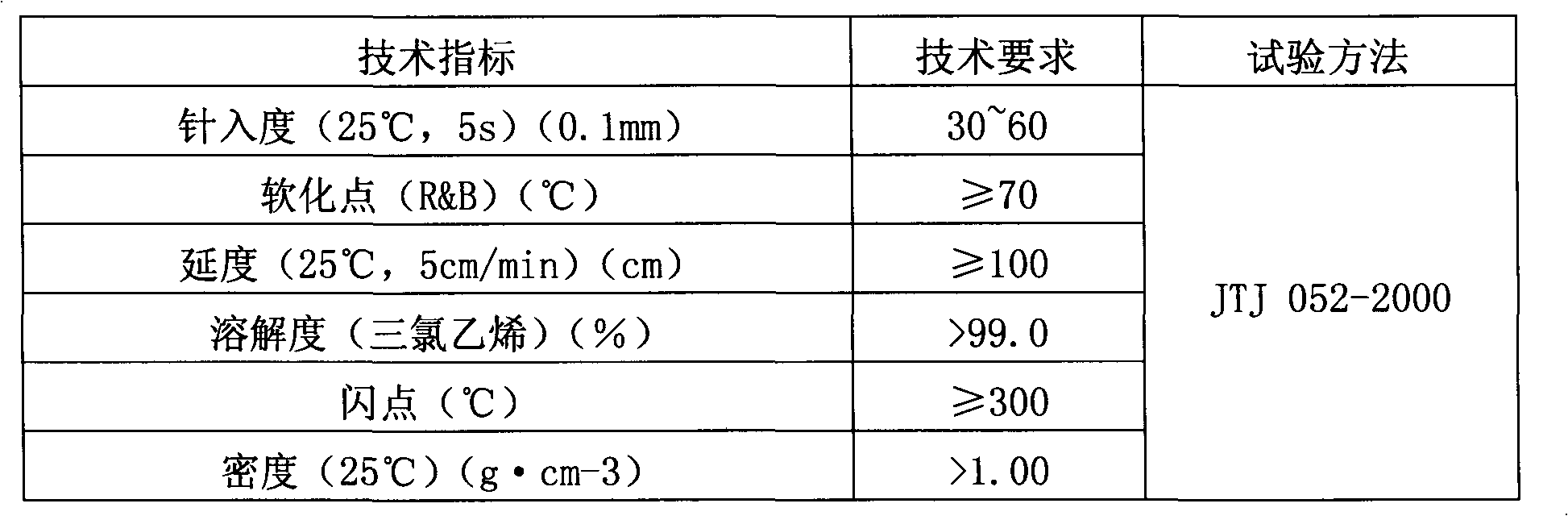

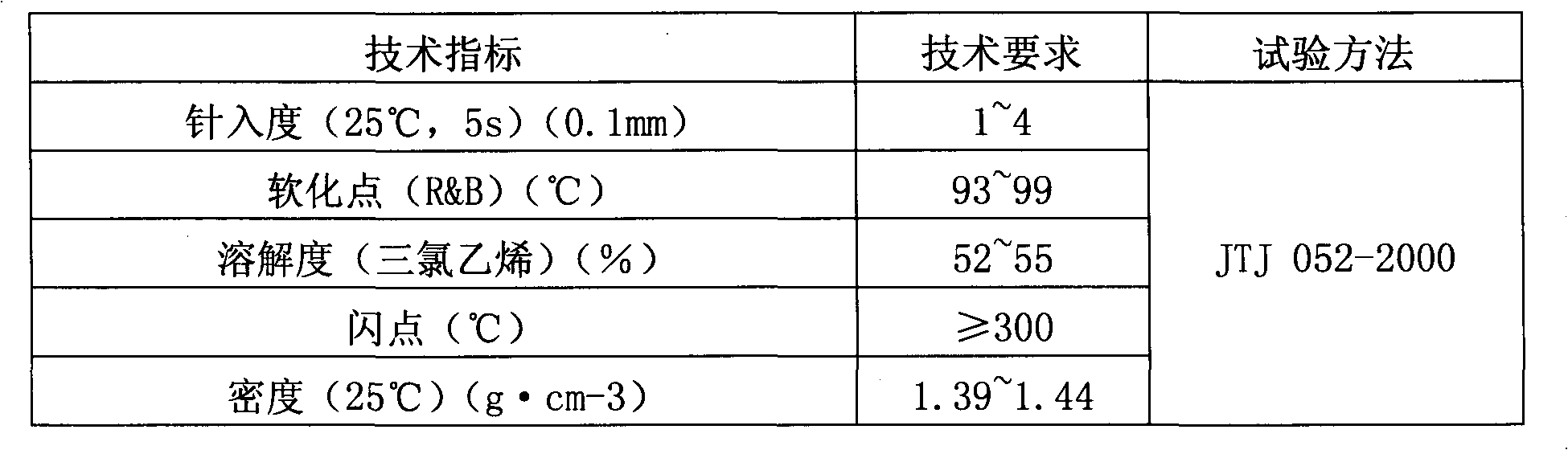

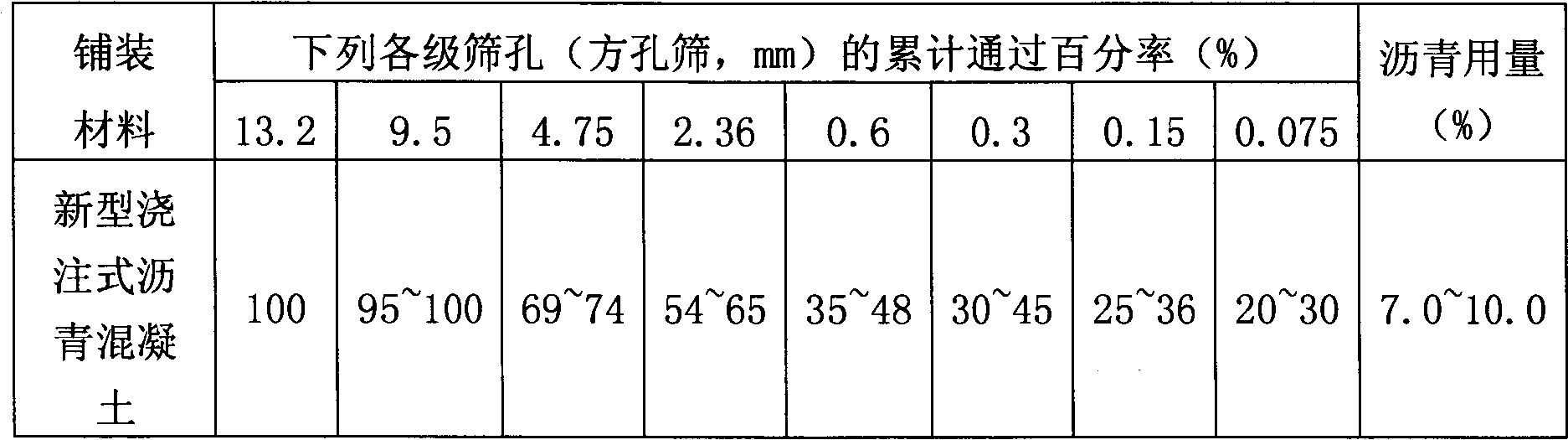

[0054]Embodiment: Each raw material is calculated by weight ratio, 10 parts of SBS modified asphalt, 15 parts of Trinidad Lake Asphalt (TLA), 280 parts of basalt aggregate, and 25 parts of mineral filler. First, put 10 parts of SBS modified asphalt and 15 parts of TLA into a special mixer at 180°C and mix evenly to make castable asphalt binder; then, add 25 parts of mineral filler into the mixer in three times to combine with castable asphalt Mix the materials and stir for not less than 60 minutes to make castable asphalt cement; secondly, add basalt aggregates that have been preheated to 220°C to 240°C into the mixer, mix with castable asphalt cement, and stir for not less than After 90 minutes, the pourable asphalt mixture is made; again, the castable asphalt mixture is poured into the vertical mold in the construction area; finally, the pourable asphalt mixture is poured into the vertical mold, and it is manually smoothed and maintained for 4 to 8 hours. Made of new pouring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com