Preparation method and application of styrax extract for tobacco

An extract, the technology of styrax, which is applied in the field of preparation of styrax extract for tobacco, can solve the problems of no tobacco flavor application, etc., and achieve the effect of improving throat comfort, reducing irritation, and rich aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

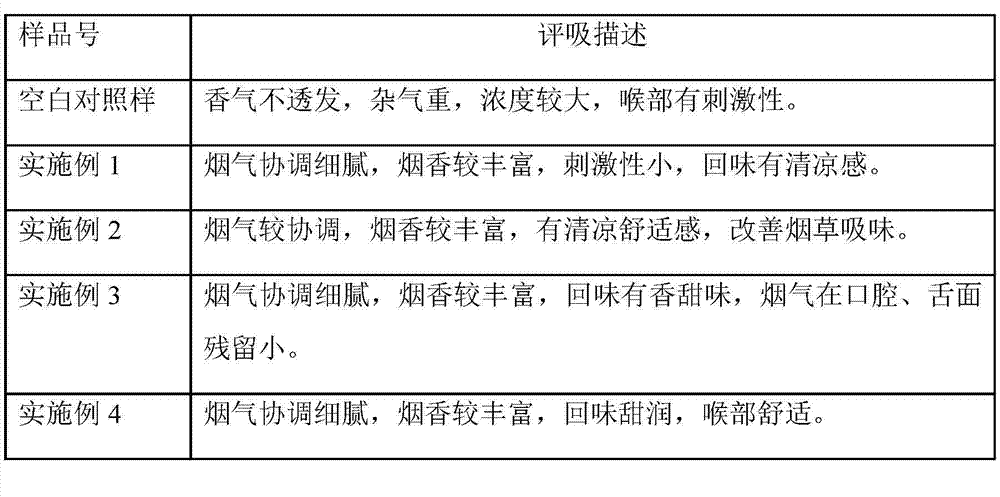

Examples

Embodiment 1

[0014] Put 100g of Styrax in a 2000ml distillation flask, add 500g of 0.5% lactic acid aqueous solution under normal pressure, heat and reflux for extraction 3 times, each time for 2 hours, filter after cooling, combine the filtrates for 3 times, and concentrate under reduced pressure at 60°C to Styrax The original weight is doubled to obtain the desired extract of storax for tobacco.

[0015] The added amount of the obtained storax extract for tobacco is 0.01% of the weight of cigarette shredded tobacco. First, dissolve the obtained storax extract for tobacco in pure water, and spray it evenly on the blank shredded tobacco according to the conventional feeding process. The shredded tobacco is dried to a moisture content of 14%, sealed and stored for 24 hours to make cigarettes.

Embodiment 2

[0017] Put 100g of Styrax in a 2000ml distillation flask, add 600g of 0.2% lactic acid aqueous solution under normal pressure, heat and reflux for extraction 3 times, each time for 3 hours, filter after cooling, combine the filtrates for 3 times, and concentrate under reduced pressure at 60°C to Styrax The original weight is doubled to obtain the desired extract of storax for tobacco.

[0018] The added amount of the obtained storax extract for tobacco is 0.05% of the weight of cigarette shredded tobacco. First, dissolve the obtained storax extract for tobacco in pure water, and spray it evenly on the blank shredded tobacco according to the conventional feeding process. The shredded tobacco is dried to a moisture content of 14%, sealed and stored for 24 hours to make cigarettes.

Embodiment 3

[0020] Put 100g of Styrax in a 2000ml distillation flask, add 700g of 0.3% lactic acid aqueous solution under normal pressure, heat and reflux for extraction 3 times, each time for 2 hours, filter after cooling, combine the filtrates for 3 times, and concentrate under reduced pressure at 60°C to Styrax The original weight is doubled to obtain the desired extract of storax for tobacco.

[0021] The added amount of the obtained storax extract for tobacco is 0.02% of the weight of cigarette shredded tobacco. First, dissolve the obtained storax extract for tobacco in pure water, and spray it evenly on the blank shredded tobacco according to the conventional feeding process. The shredded tobacco is dried to a moisture content of 14%, sealed and stored for 24 hours to make cigarettes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com