Speed changer

A transmission and synchronizer technology, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of small speed ratio range, failure to meet environmental protection, poor power performance, etc., and achieve large speed ratio range and growth The effect of long life and light gear shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

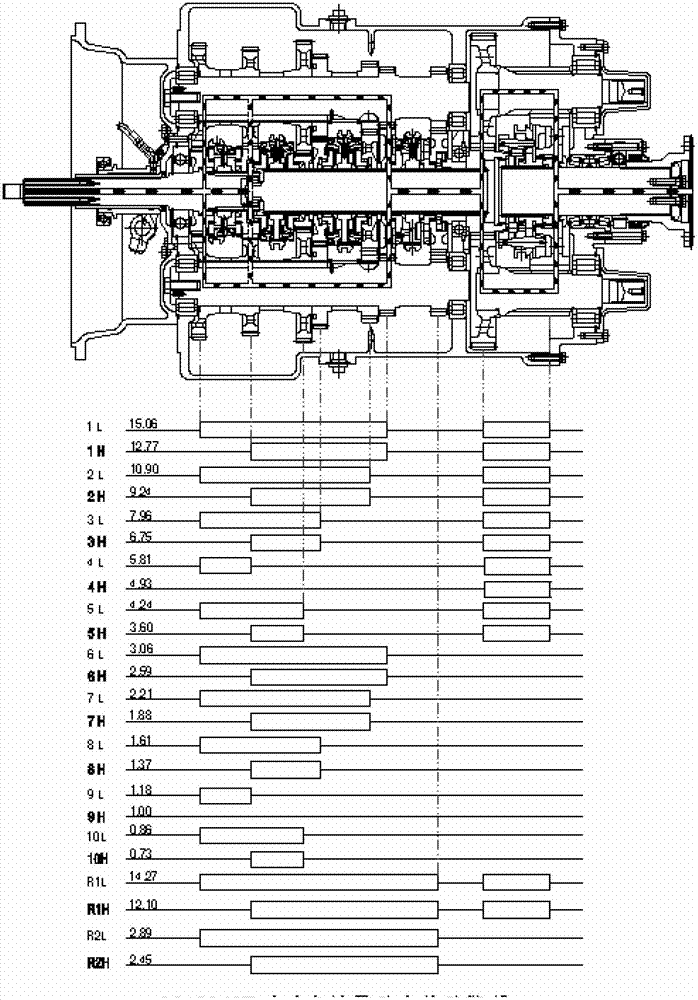

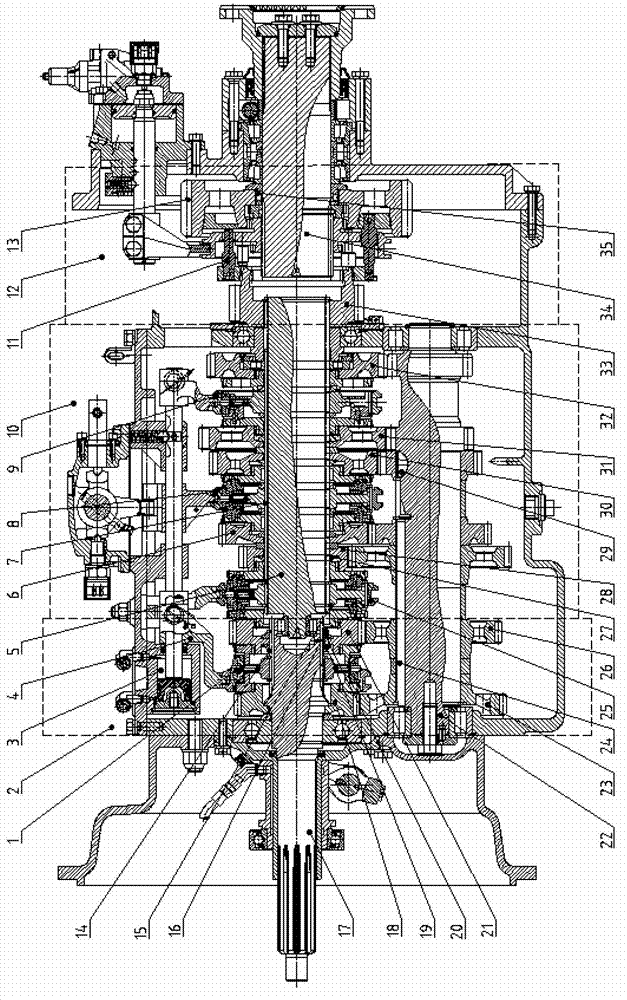

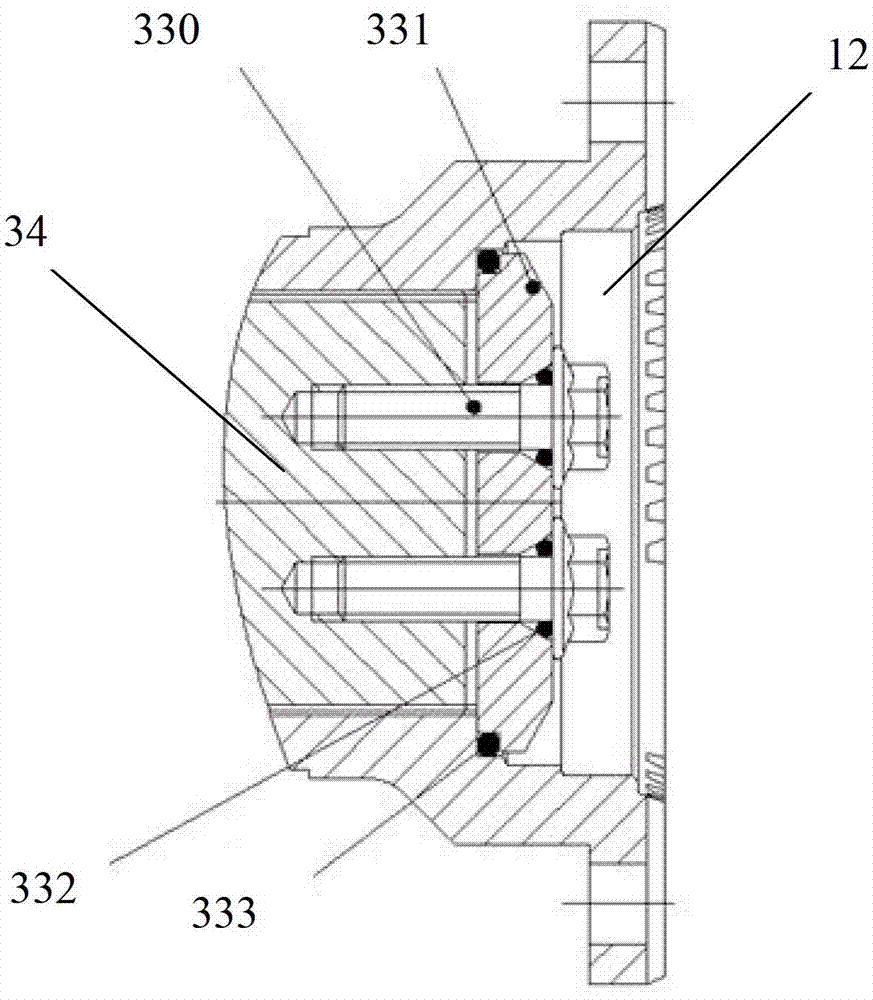

[0027] see figure 1 , 20JS240T transmission is a 2x5x2 structure composed of front auxiliary box, rear auxiliary box and main box. The one-axis gear 21 is vacantly sleeved on the one-axis 17, and the axial positioning is carried out by the first spline washer 19, the second spline washer 20 and the stop ring 15, the structure is simple, the assembly is convenient, and the adjustment pad is omitted The trouble of adjusting; the one-axis differential gear 18 is also vacantly sleeved on the one-axis 17; a single-taper, one-way lock ring type inertia synchronizer 1 is housed between the one-axis gear 21 and the one-axis differential gear 18, the The synchronizer is operated by air, and the gear is shifted through the shift fork 4 by the cylinder 3 on the main box body. The gears on the intermediate shaft 22 are all matched with the intermediate shaft 22 with a certain amount of interference except that the first gear 31, the second gear 30 and the reverse gear 32 are integrated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com