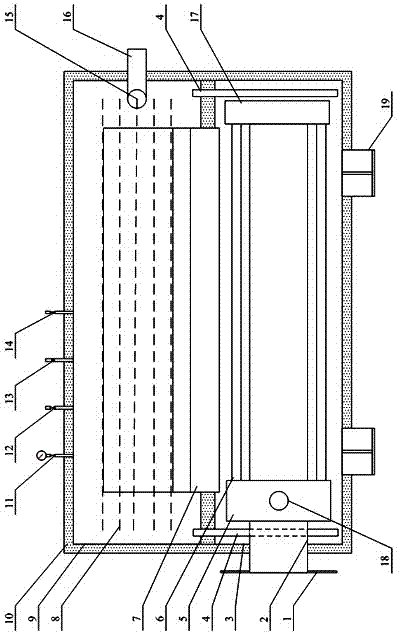

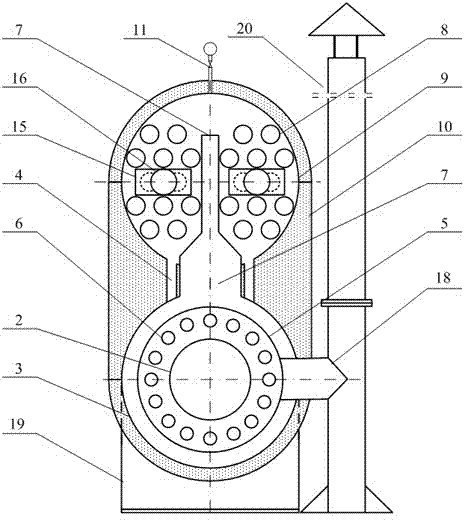

Heat resistance-free heat pipe heating furnace and heating method thereof

A technology of heating furnace and heat pipe heat exchanger, which is applied to heat storage heaters, fluid heaters, lighting and heating equipment, etc. The heat exchange effect of the heat exchange system and other issues can achieve the effects of green environmental protection, social and economic benefits, increase the heat transfer rate of the phase change, and have a significant energy saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] Its normal operation implementation method includes the following steps:

[0046]1. After the installation and connection of the non-resistance heat pipe heating furnace and the process of the heated medium are completed, it must be checked to ensure that the heated medium and the gas source process of the non-resistance heat pipe heating furnace are correct. Then, the non-resistance heat pipe heating furnace is evacuated, and the pressure in the cavity is required to be ≤-0.07.

[0047] 2. When the non-resistance heat pipe heating furnace achieves the required vacuum degree, the burner can be ignited, the gas volume can be controlled by the gas volume control valve, and the chimney suction can be controlled by the chimney seat to make the gas burn fully. After fifteen minutes, turn the flow on gradually. After about 30 minutes, use a thermometer to detect the temperature of the heated medium outlet of the heating furnace, and adjust the gas volume to reach the require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com