Warm type high-speed forming device for experiments

A warm forming and experimental technology, applied in the field of experimental devices, can solve the problems of not being able to achieve precise heating and rapid cooling of difficult-to-form materials at the same time, and inability to accurately control temperature, and achieve the effects of compact structure, simple structure and increased safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

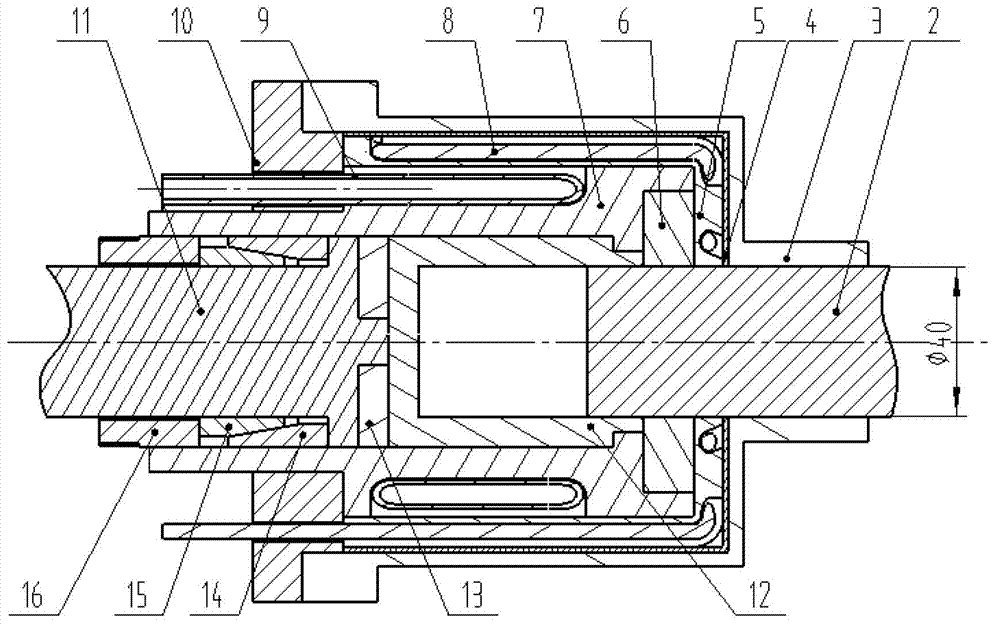

[0039] In the experiment, an aluminum-magnesium alloy sheet with a thickness of 1 mm and a diameter of 60 mm was impact-formed with a warm-type high-speed forming device, and the forming temperature was 500 °C. During the test, the above-mentioned magnesium-aluminum alloy sheet was placed between the blank holder 6 and the die sleeve 7, and the workpiece was pre-tightened by tightening the blank holder 6. The heating temperature was 500°C, the heat preservation was 30 minutes, and the punch speed was 200m / s under the impact forming experiment. After the experiment, a super-resolution Axio CSM 700 true-color confocal microscope was used to detect the three-dimensional shape, forming depth and forming quality of the formed workpiece samples. The results show that the forming depth, forming surface integrity and forming quality of the formed parts are greatly improved, and the forming cracking defects are significantly reduced.

[0040] In addition, after the experiment, the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com