Auxiliary equipment for continuous casting solidification structure image scanning and application method thereof

A technology of solidification structure, imaging and scanning, which is applied in the preparation of test samples, measuring devices, and material analysis through optical means, etc. It can solve the problem of not being able to meet the inspection of metallographic dendrite structure, and not applicable to the original heavy sample of cast slab with 3 degrees of freedom 180-degree rotation and other problems in motion, to achieve the effect of improving scanning imaging efficiency, compact structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

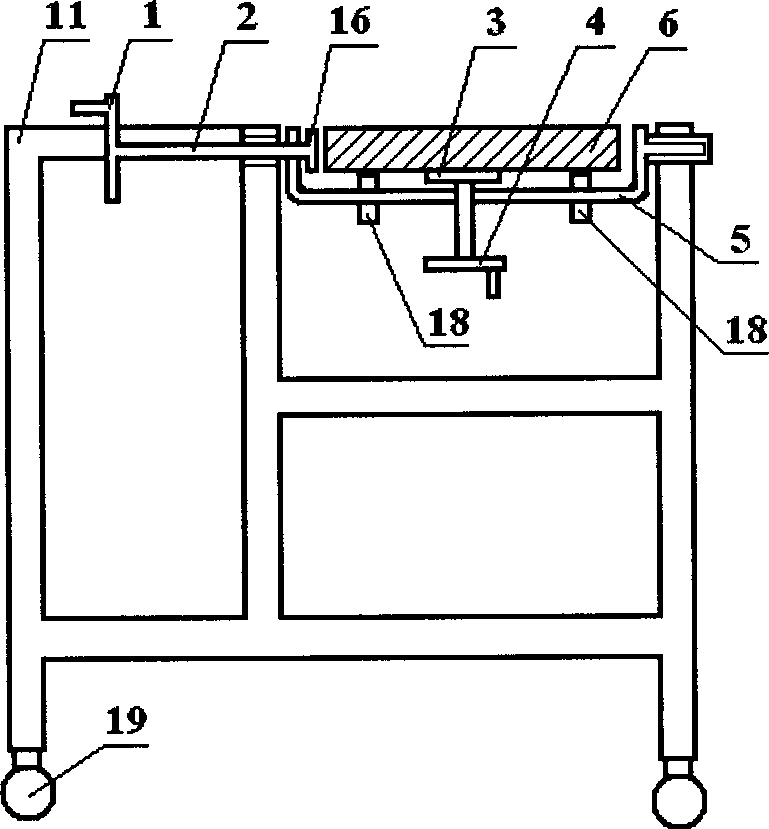

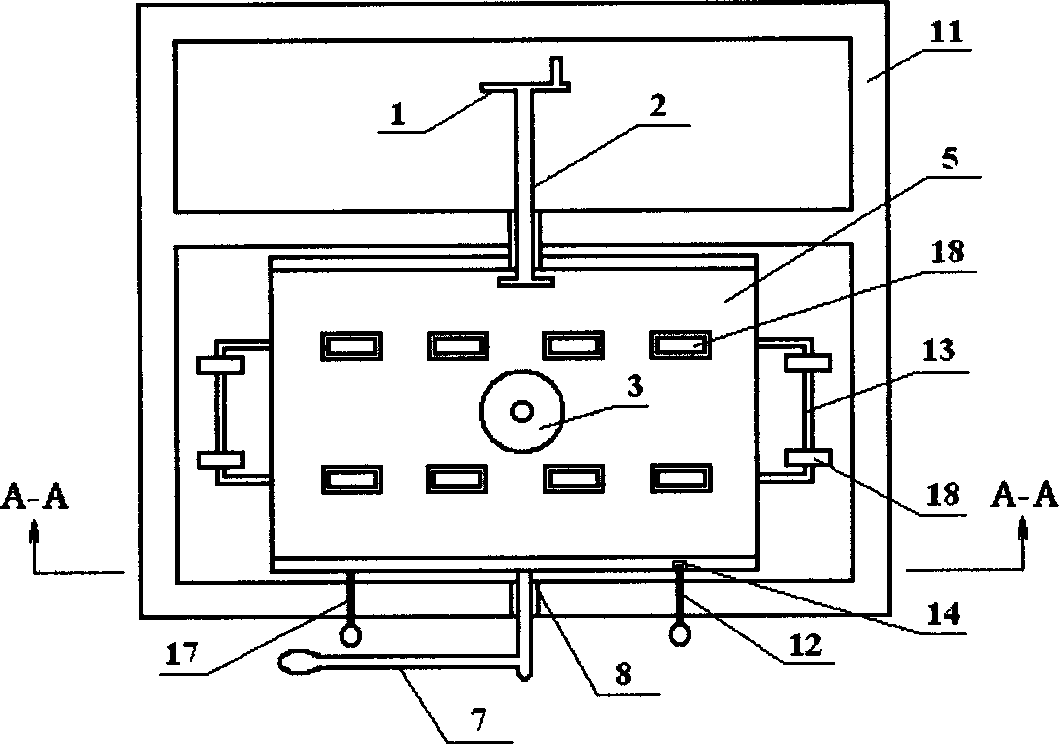

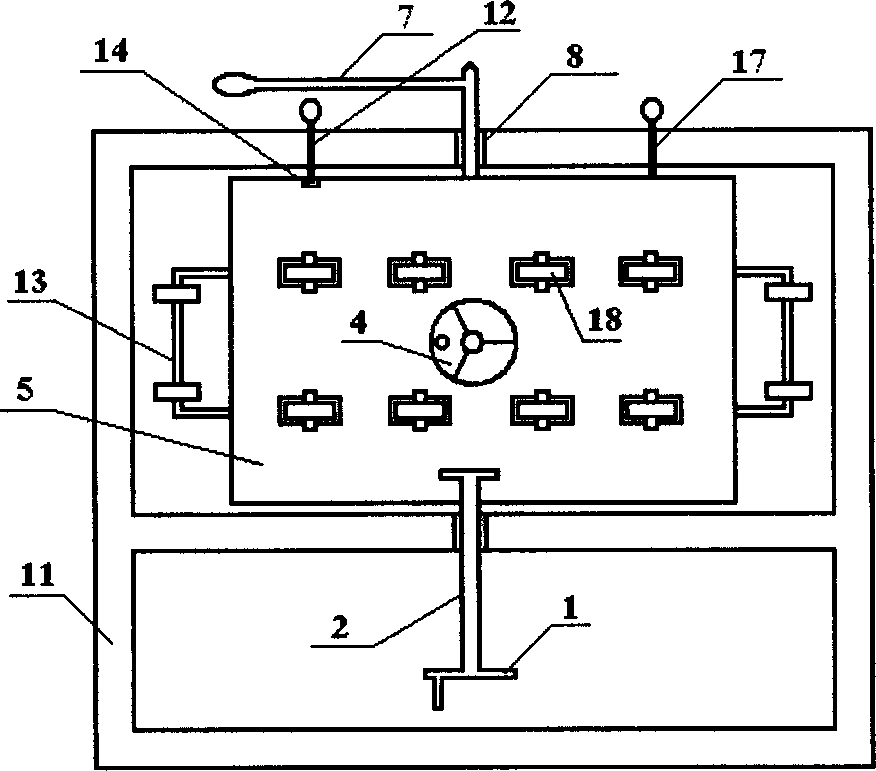

[0016] The present invention will be further described below with reference to the accompanying drawings.

[0017] It is not difficult to see from the accompanying drawings that the auxiliary equipment for imaging and scanning of the solidified structure of the continuous casting slab consists of two parts: a sample turning device and a scanner lifting device. The sample inverting device is mainly composed of a bracket 11 and a sample bracket 5 . Described support 11 is square, and available metal pipe is done, and a universal wheel 19 is respectively installed on the four pins of its lower end, can move toward arbitrary direction. The sample bracket 5 is U-shaped, and each side is connected to the upper frame of the bracket 11 through a bushing 8 . A fastening screw 2 is worn in the shaft sleeve 8 inside the sample bracket 5, one end of the fastening screw 2 is provided with a fastening handle wheel 1, and the other end is provided with a fastening disc 16, and the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com