Methods of balancing production lines in the industrial sewing industry

A production line and production line balance rate technology, applied in the computer field, can solve problems such as waste of human resources, incorrect adjustment of production lines, and low supervision efficiency, so as to reduce waiting time, save human resources, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

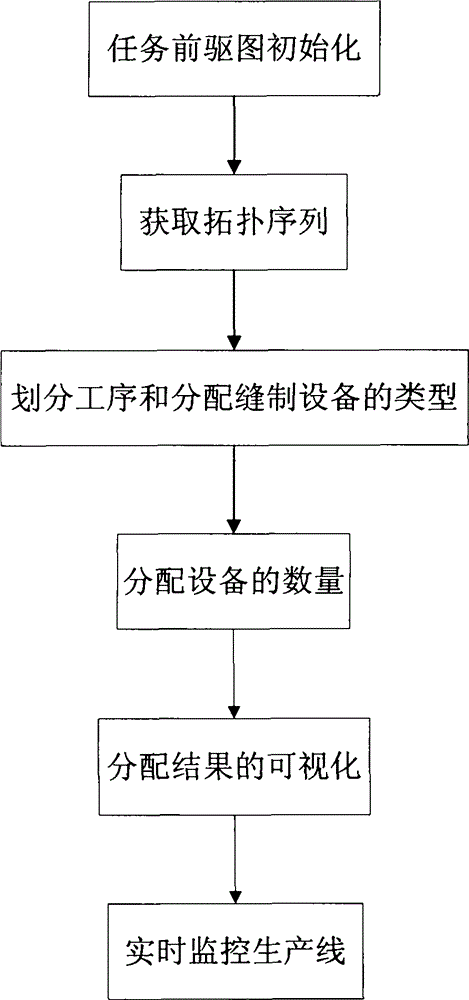

[0033] Refer to attached figure 1 , The specific implementation steps of the present invention are as follows.

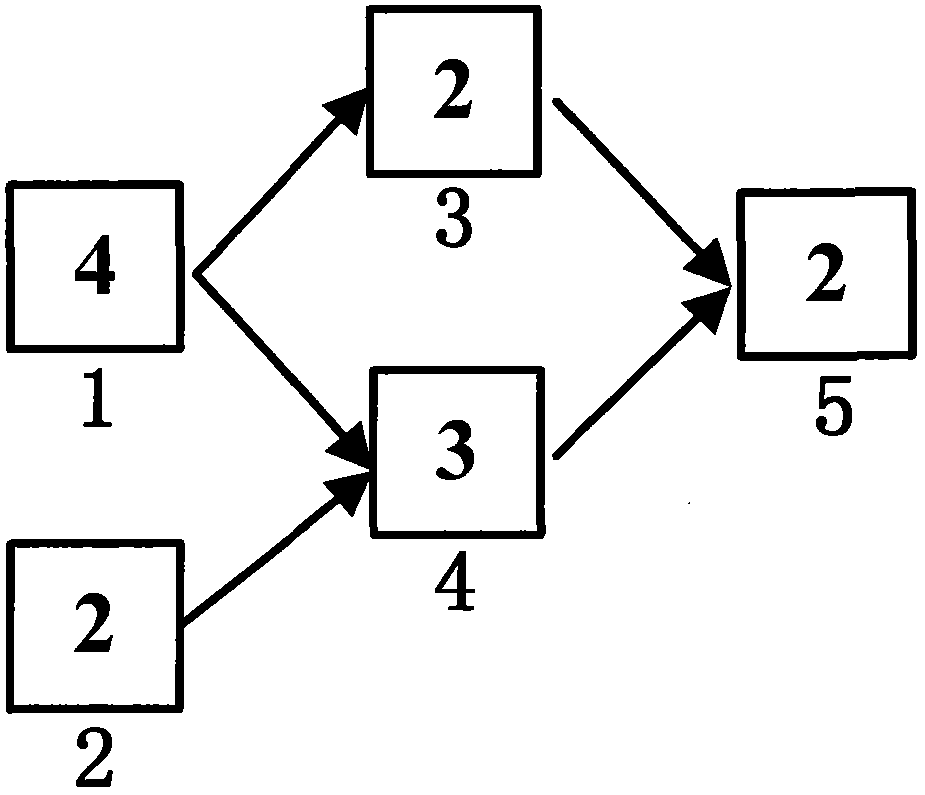

[0034] Step 1, Task Precursor Graph Initialization

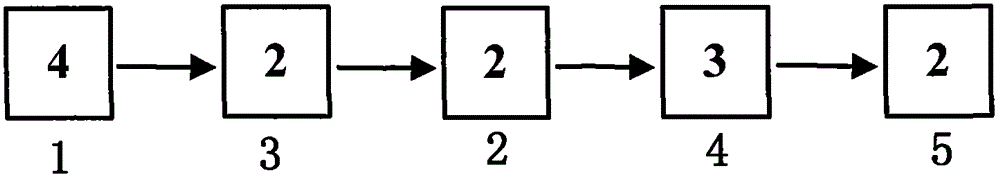

[0035] The task nodes on the production line are represented by rectangular boxes, and the rectangular boxes are numbered one by one starting from 1 according to the task execution process, and the rectangular boxes are connected according to the sequence dependencies of the tasks to generate the task precursor graph. In the present invention, the generated task predecessor map is as attached figure 2 As shown, the rectangles in the figure represent the tasks on the production line, the numbers below the rectangles indicate the order in which tasks are executed on the production line, the numbers in the rectangles indicate the time it takes to complete the task, and the direction of the arrow indicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com