Dynamic scan driving method for smectic phase LCD (liquid crystal display)

A liquid crystal display and driving method technology, applied to static indicators, instruments, etc., can solve the problems of aggravated cumulative effect of swiping the screen and waste of electric energy, etc., and achieve the effects of reducing power consumption, reducing the cumulative effect of swiping the screen, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

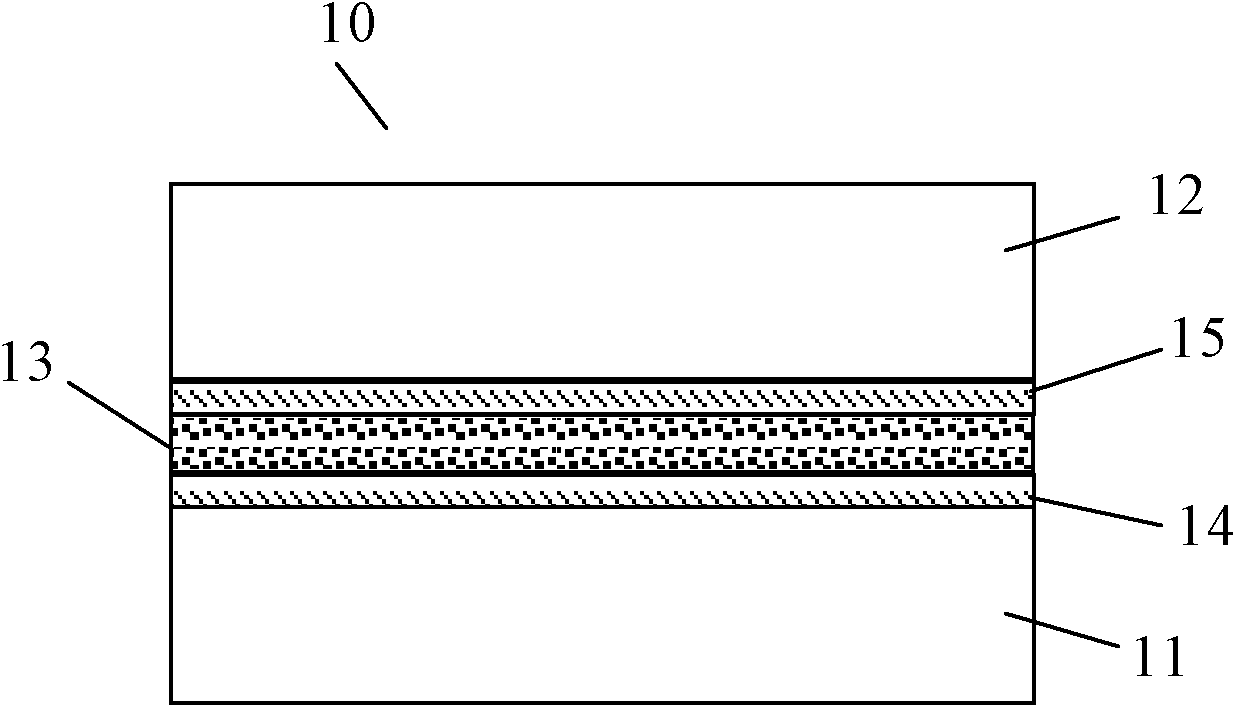

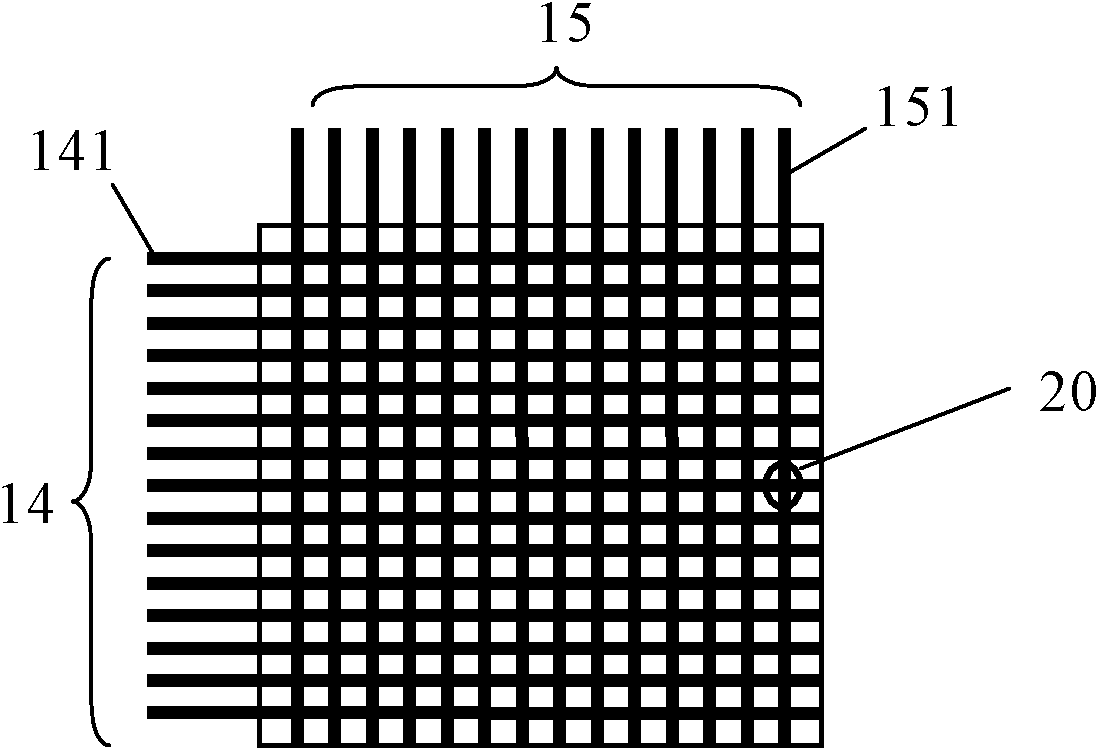

[0022] The dynamic scanning driving method of the smectic phase liquid crystal display screen of the present invention is a method for the smectic phase liquid crystal display screen. Such as figure 2 and image 3 As shown, the smectic liquid crystal display screen 10 includes a first base layer 11 and a second base layer 12, and the material of the first base layer 11 and the second base layer 12 can be transparent glass or plastic. Between the first base layer 11 and the second base layer 12, there is a mixed layer 13 formed by mixing smectic liquid crystals and additives. The smectic liquid crystals (also known as smectic liquid crystals, microscopically shown as smectic liquid crystal molecules, see below) are compounds with siloxy groups, tetracyanotetraoctylbiphenyl or tetradecyl tetraacetate Any one or any mixture of cyanobiphenyls. The additives are compounds with conductive properties, such as hexadecyltriethylammonium bromide and other compounds containing conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com