Fruit unshelling device

A fruit and driving device technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of chestnut shelling machine complex structure, easily damaged rack, inconvenient use, etc., to achieve a wide range of use, prevent damage, ensure The effect of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

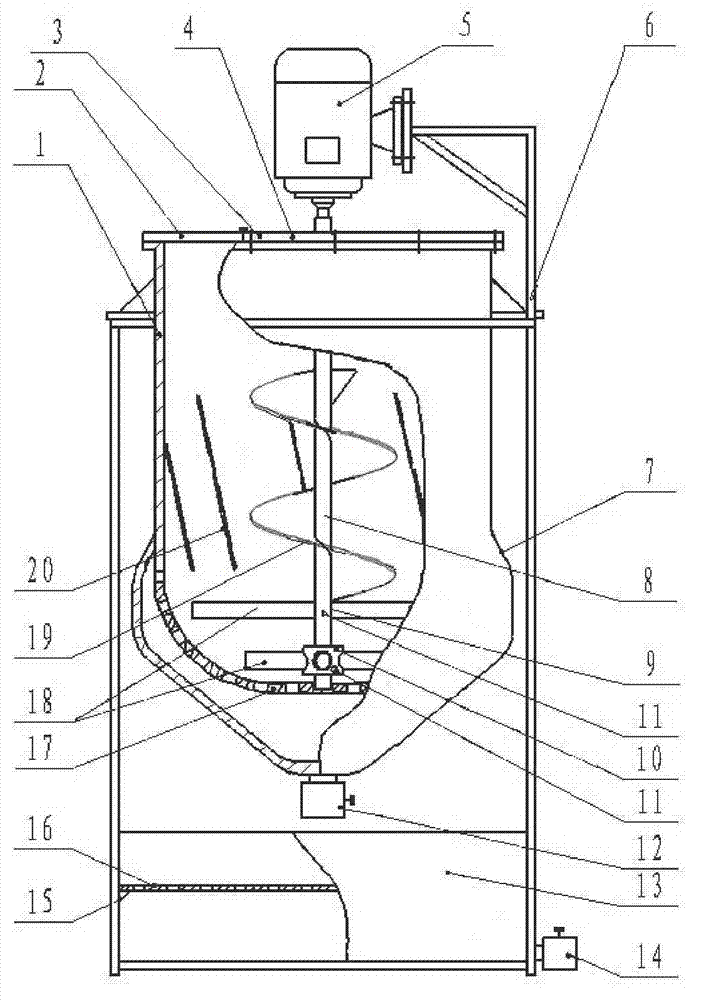

[0027] A shelling device used for shelling red cone fruit, its structure includes a cylinder body 1, a movable cover plate 2, a fixed cover plate 3, a drive device 5 for a variable speed motor, a frame 6, a jacket 7, a stirring shaft 8 and The cylinder body 1 is coaxially installed, and the part protruding from the upper end of the fixed cover plate 3 is connected with the driving device 5, and the lower end is installed in the central positioning hole of the cylinder bottom hole plate 17 with bearings, and the two ends are fixed, and the agitator runs when it is working. Stablize. A propeller 19 is welded on the stirring shaft 8; the stirring rod 18 made of synthetic rubber into an elliptical column rod is inserted into the jack 9 on the stirring shaft 8 below the propeller 19, and fixed on the stirring shaft 8 by a pin 11; the bottom One group of stirring rods 18 is made up of two cylindrical rods, is fixed on the stirring shaft 8 with pin 11 by sleeve 13. Barrel 20 is arra...

Embodiment 2

[0029] A shelling device for shelling chestnut fruit, the structure of which includes a cylinder body 1, a movable cover plate 2, a fixed cover plate 3, a driving device 5, a frame 6, a jacket 7, a stirring shaft 8 and a cylinder body 1 Coaxial installation, the part protruding from the upper end of the fixed cover plate 3 is connected with the driving device 5, and the lower end is installed in the center positioning hole of the bottom orifice plate 17 of the cylinder, and the two ends are fixed, so that the agitator operates stably during operation. A propeller 19 is welded on the stirring shaft 8; the stirring rod 18 provided at the upper end of the propeller 19 is inserted into the jack 9 on the stirring shaft 8, and is fixed on the stirring shaft 8 by a pin 11, and the stirring rod 18 at the lower end of the propeller is composed of two, Through the sleeve 13, the pin 11 is fixed on the stirring shaft 8, so that the stirring rod 18 is fixed on the stirring shaft 8; the sti...

Embodiment 3

[0031]A shelling device for Indian chestnut fruit shelling, its structure includes a cylinder body 1, a movable cover plate 2, a fixed cover plate 3, a driving device 5, a frame 6, a jacket 7, a stirring shaft 8 and the cylinder body 1 Coaxial installation, the part protruding from the upper end of the fixed cover plate 3 is connected with the driving device 5, the lower end is installed in the center positioning hole of the bottom orifice plate 17 of the cylinder, and the two ends are fixed, so that the agitator operates stably during operation. The propeller 19 is cast together with the stirring shaft 8; the stirring rod 18 provided at the upper end of the propeller 19 is inserted into the socket 9 on the stirring shaft 8, and fixed on the stirring shaft 8 by a pin 11, and a group of stirring rods 18 at the lower end of the propeller 19 are formed by Composed of three, through the sleeve 13, fixed on the stirring shaft 8 with the pin 11, so that the stirring rod 18 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com