Dust suction device for horizontal centrifugal casting machine

A technology of centrifugal casting machine and dust collection device, which is applied in the direction of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as dust pollution, and achieve the effects of reasonable structure, improved work enthusiasm, and effective use of space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

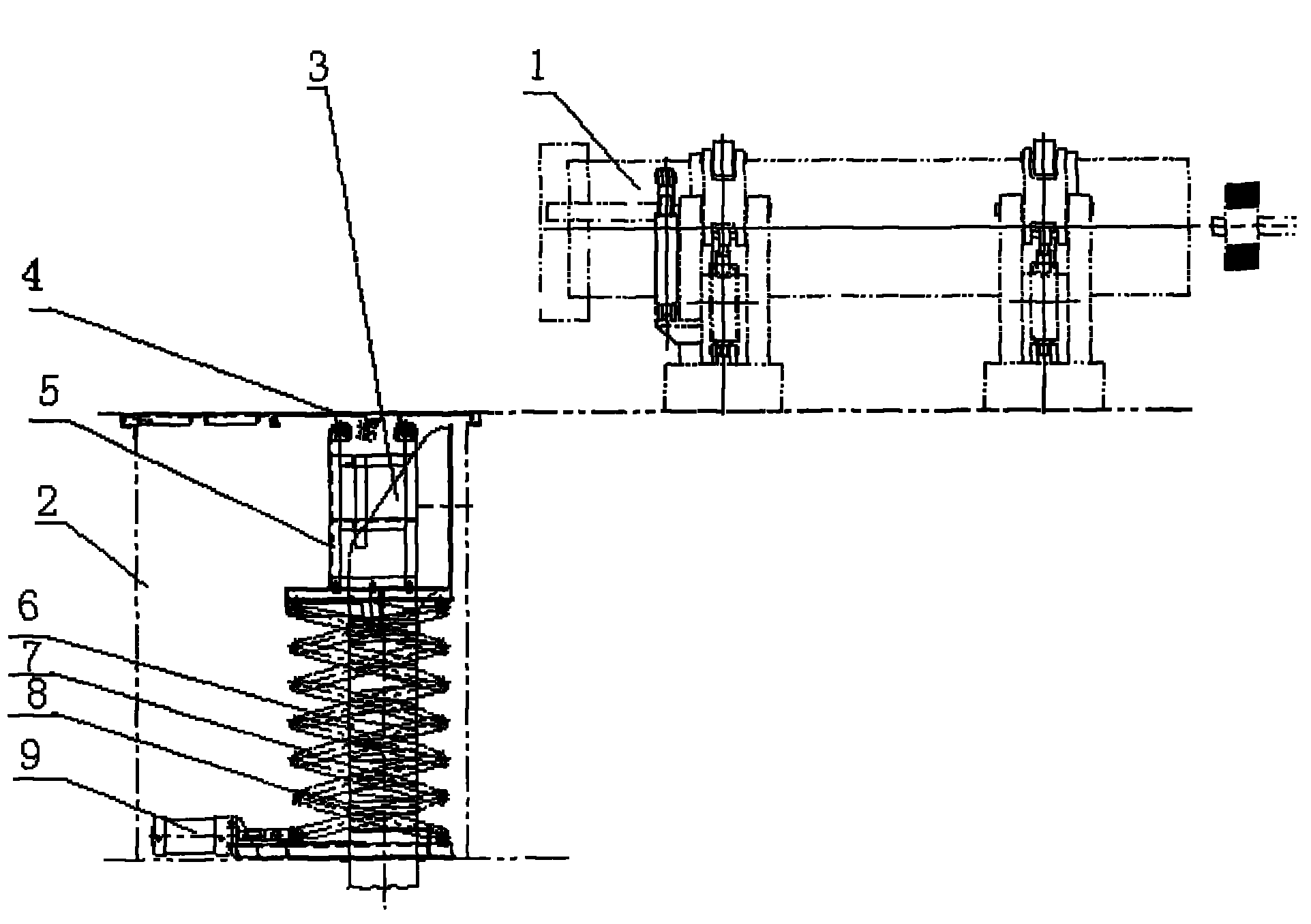

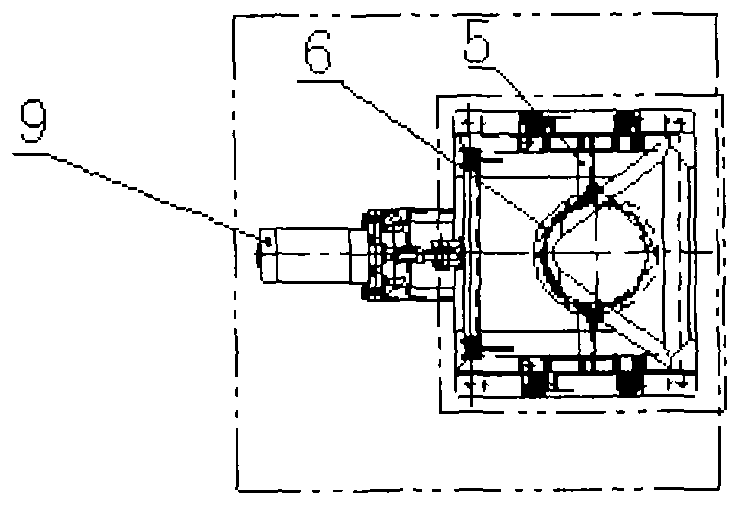

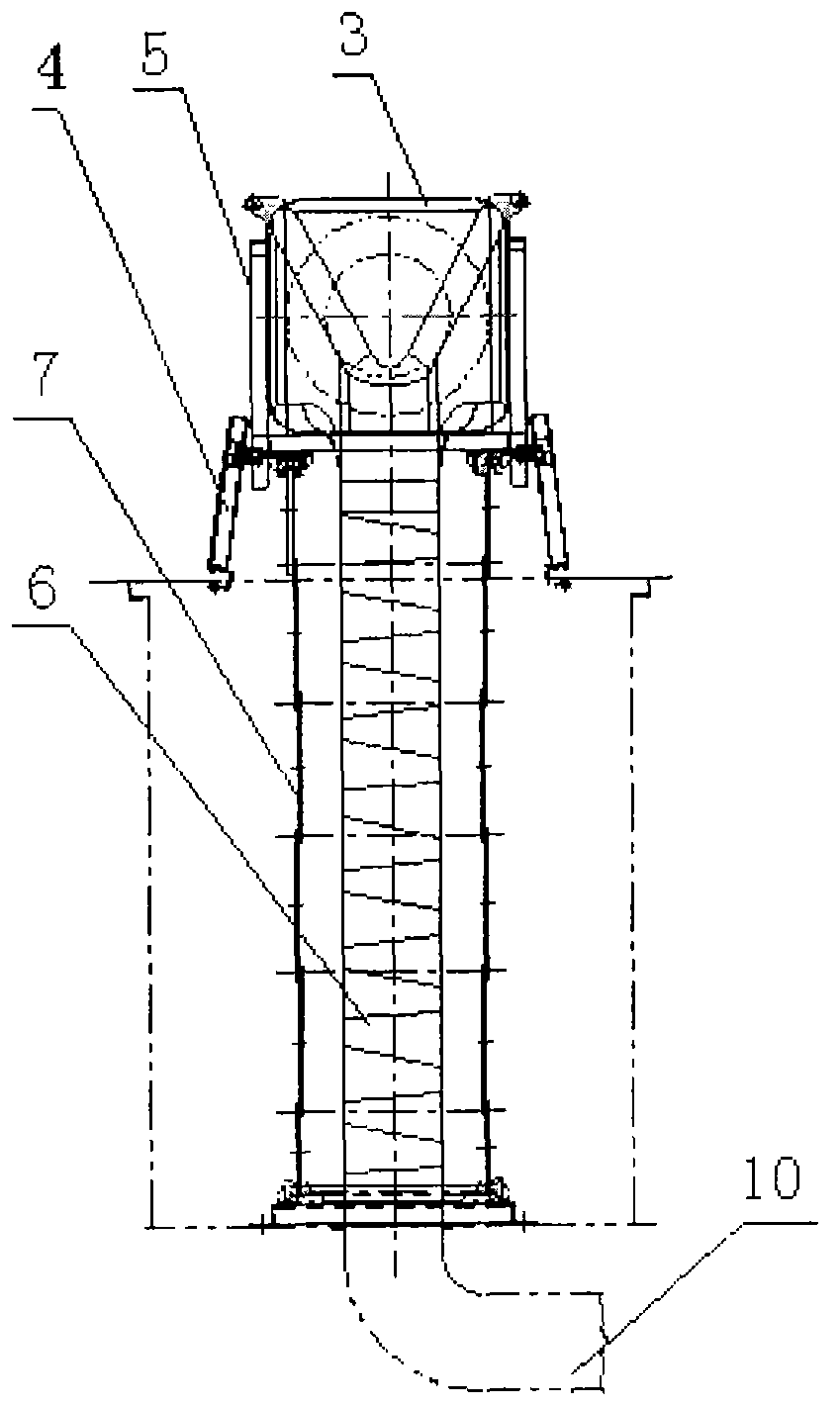

[0013] refer to Figure 1-Figure 3 , the dust suction device of the horizontal centrifugal casting machine in this embodiment, the front end of the casting machine 1 is provided with a pit 2 underground, the dust suction device is arranged in the pit 2, the pit mouth is covered with a pit cover plate 4, and the pit cover plate 4 One side is connected with the edge of the pit through a rotating pair. Described dust suction device comprises dust collection cover 3, scissors frame 7, connecting rod 5, and described dust collection cover 3 is installed on the upper platform of scissors frame 7, and described connecting rod 5 one ends are fixedly connected with the upper platform of scissors frame 7 , the other end is hinged on the pit cover 4, and the hinge point is away from the connection between the pit cover 4 and the edge of the pit. The dust collection device also includes an air duct 6, an air valve 8 and a vacuum cleaner. The upper end of the air duct 6 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com