Tungsten steel flat drill

A tungsten steel and flat drill technology, which is used in repairing drills, drilling tool accessories, drilling/drilling equipment, etc. The effect of improving work efficiency, large chip removal space and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

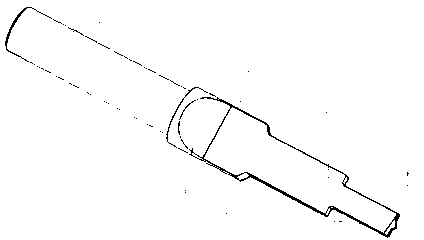

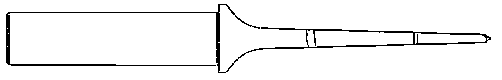

[0009] Examples, see figure 1 , 2

[0010] A kind of tungsten steel flat drill of the present embodiment comprises an integrally formed blade 1 and a handle 2, which is made of tungsten steel material, the handle is a cylindrical straight handle, the blade is stepped, and the blade There is a transition part 3 between the knife handle, the bottom end of the transition part 3 is a circular platform, and an arc surface chip removal groove 4 is formed from the circular platform to the rake face of the blade. The blade is a two-stage type, located at the front end of the blade It is the first stage, and its width increases step by step, wherein, the cutting edge 5 of the primary and secondary blades is arranged on the edge of the blade, and a cutting edge 6 is arranged on the top of the primary blade, and the connection between the secondary blade and the transition part is also has a 45 Set of cutting edges7.

[0011] In this embodiment, the tungsten steel flat drill has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com