Lens rounding machine cutter

A circular machine and cutting tool technology, which is applied in the field of lens grinding machine cutting tools, can solve the problems of affecting the appearance quality of glass and increasing wear, so as to reduce wear and ensure the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

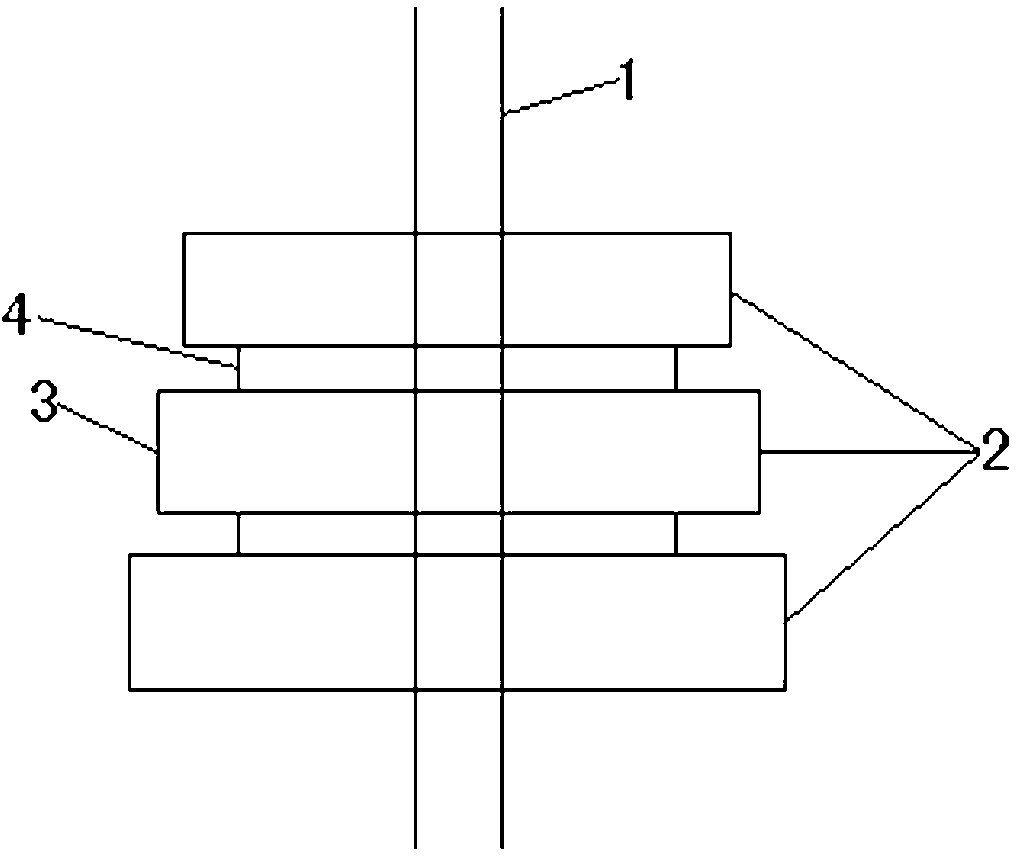

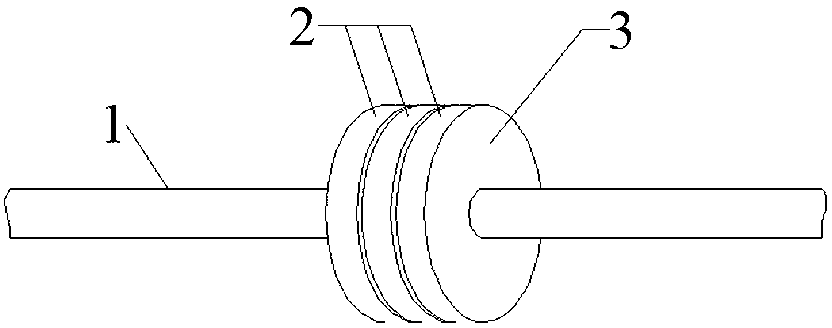

[0015] As shown in the accompanying drawings, a cutting tool of a lens rounding machine is provided with a grinding wheel 2 on the rotating shaft 1, and the grinding wheel 2 includes a plurality of sub-grinding wheels 3 arranged coaxially, and the meshes of the sub-grinding wheels 3 increase sequentially along the axial direction; A spacer 4 is arranged between the sub-grinding wheels, and the outer diameter of the spacer 4 is slightly smaller than that of the adjacent sub-grinding wheels.

[0016] Further, the mesh numbers of the sub-grinding wheels 3 are respectively 240 mesh, 360 mesh, and 500 mesh respectively, and the diameter of the sub-grinding wheels increases with the increase of the mesh number. When in use, the lens square column to be rounded is ground successively by 240-mesh, 360-mesh, and 500-mesh grinding wheels, and the diameter of its circumscribed circle becomes smaller along the axial direction. The front and rear parts of the lens square column can be well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com