Combining production line for PVC inner ring moulds of pet balls

A pet ball and production line technology, applied in the field of pet ball PVC inner ring mold pairing and flipping production line, can solve the problems of inability to meet automatic production, high labor intensity, low work efficiency, etc., and achieve high work efficiency, low labor intensity, Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

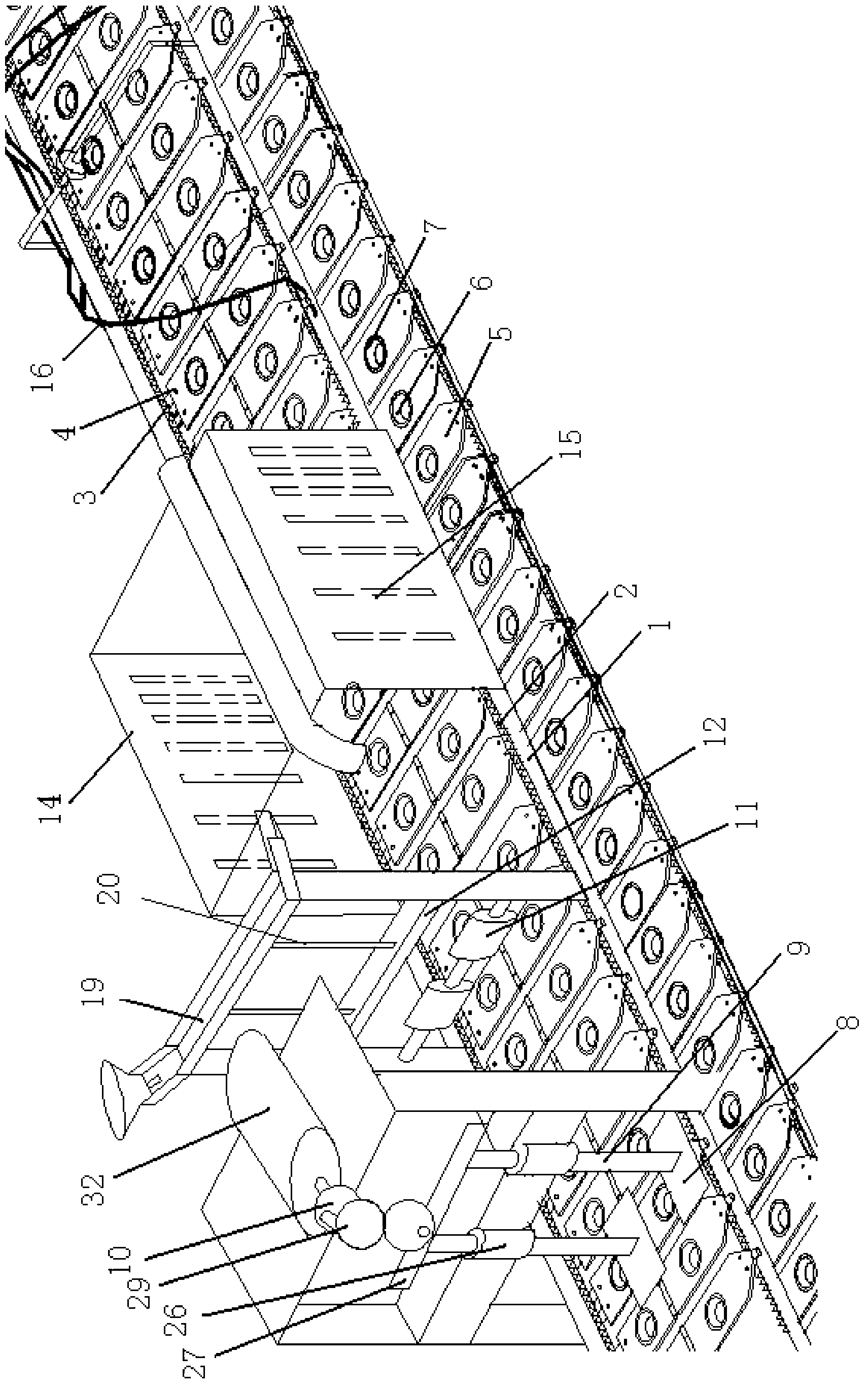

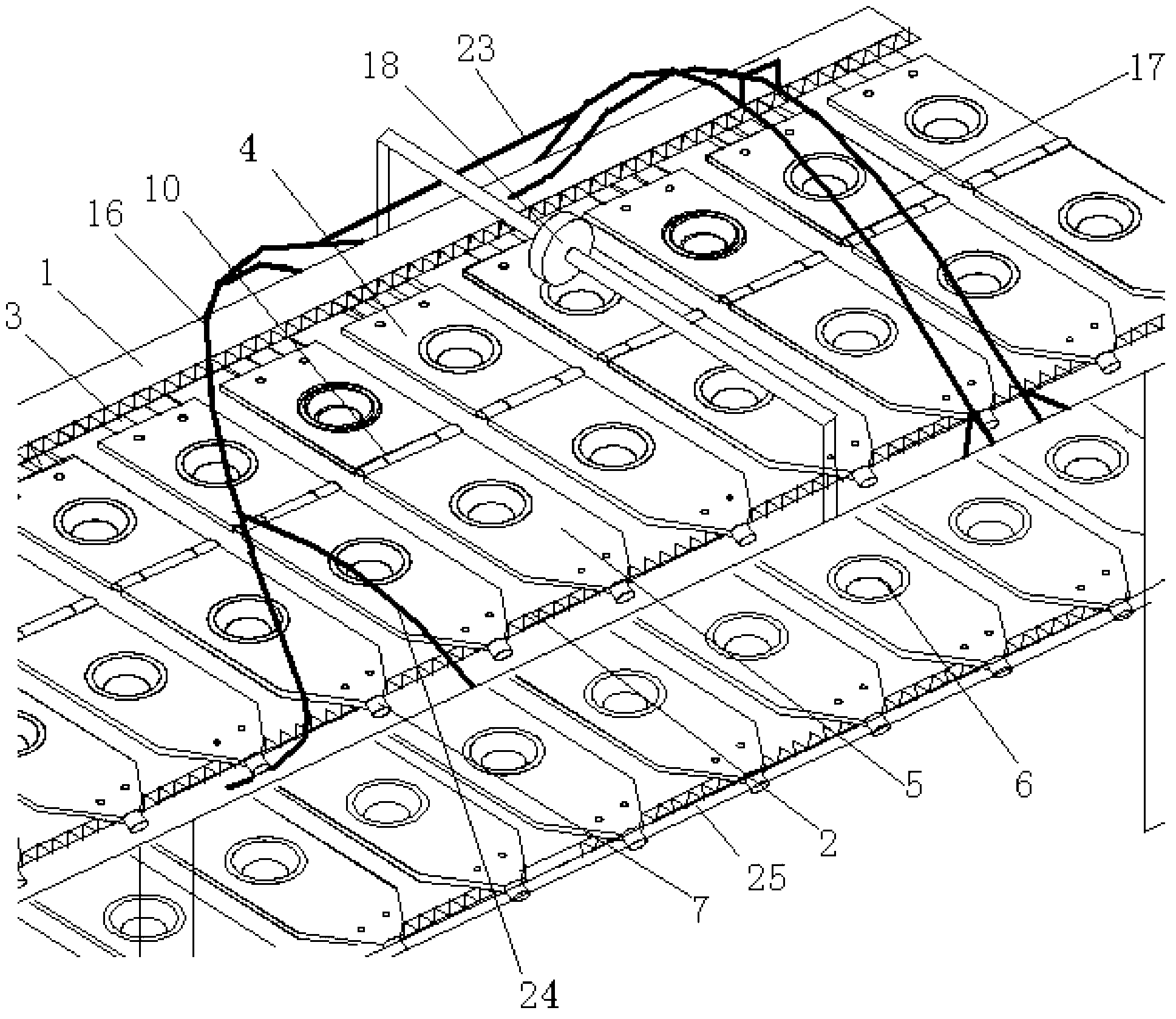

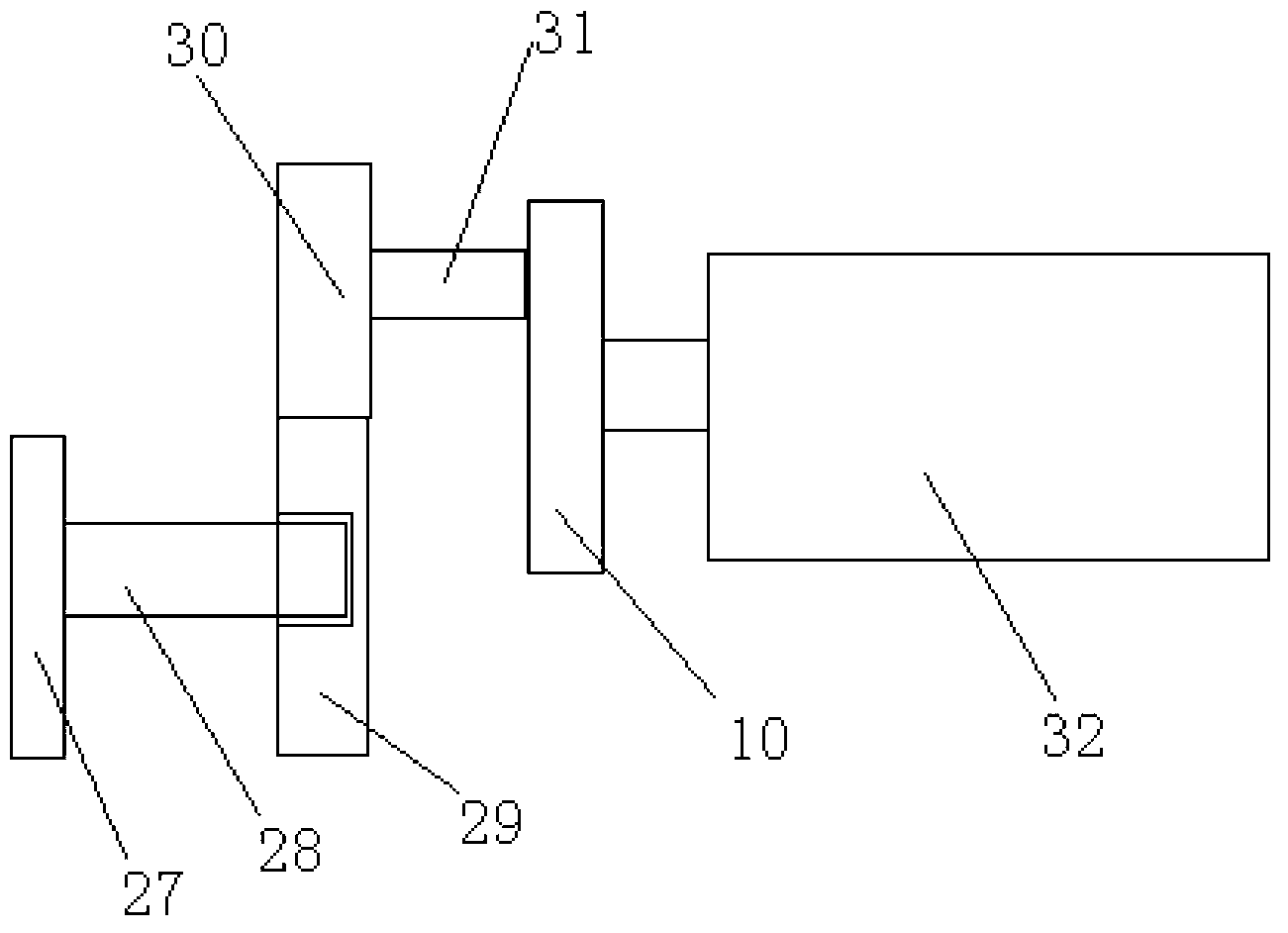

[0021] Referring to the accompanying drawings, a pet ball PVC inner ring mold matching production line includes a conveying template mechanism, a molding mechanism, a glue coating mechanism, a heating mechanism, and a turning mechanism. There is a circular conveying chain 2 between them, and a conveying plate 3 is laid between the circulating conveying chains 2. On the conveying plate 3, there are left and right templates 4, 5 that can be combined. The left and right templates 4, 5 are respectively provided with mutual The corresponding concave cavity 6, the left and right templates 4 and 5 at the edge of the concave cavity 6 are respectively provided with corresponding annular bosses 7; 9 at the bottom end, the guide rod 9 is driven by the eccentric wheel 10; the gluing mechanism is located at the rear of the die mechanism, including two gluing rollers 11, and a corresponding gluing groove 12 is arranged above the gluing roller 11, and the gluing groove 12 A sponge body 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com