Embedded multidirectional frame connection node for packing case

A technology for connecting nodes and packaging boxes, applied in the engineering field, can solve the problems of low node connection strength, poor commonality of nail connection nodes, waste of wood resources, etc., to increase safety and reliability, facilitate standardized production, and require low processing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

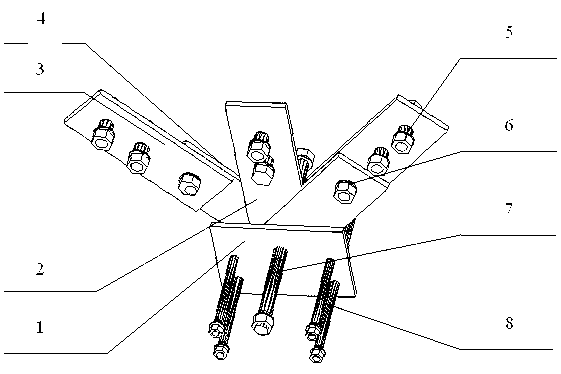

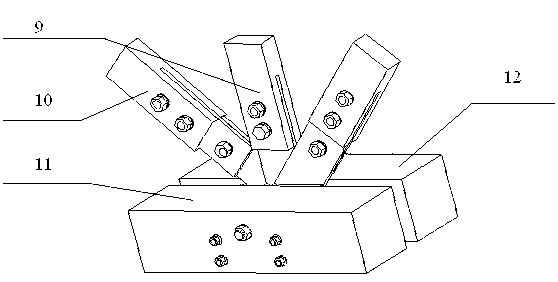

[0015] Referring to the accompanying drawings, its structure includes an embedded steel plate base 1, A multi-directional steel plate connecting arm 2, B multi-directional steel plate connecting arm 3, and C multi-directional steel plate connecting arm 4, wherein the embedded steel plate base 1 and A multi-directional steel plate The connecting arm 2 and the C multi-directional steel plate connecting arm 4 are hinged, and the C multi-directional steel plate connecting arm 4 is hinged with the B multi-directional steel plate connecting arm 3 again.

[0016] The embedded steel plate base 1 is embedded in the frame tray of the packing box, and the frame tray adopts a double-beam form, and the embedded steel plate base 1 is embedded between the A frame pallet beam 11 and the B frame pallet beam 12, and the steel plate is embedded The base 1 is tightly connected with the pallet beam 11 of the A frame and the pallet beam 12 of the B frame through D bolts and nuts 8; Nut 7 is hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com