Planet gear embedded reversing engine with interlocking for multifunctional working vehicle

A technology for planetary gears and working vehicles, which is applied to gear transmissions, belts/chains/gears, hoisting devices, etc. It can solve the problems of shortened life, impact on driving safety, and insufficient slowness of backward deceleration, etc., to achieve reasonable structure and reduce Manufacturing cost, effect of longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

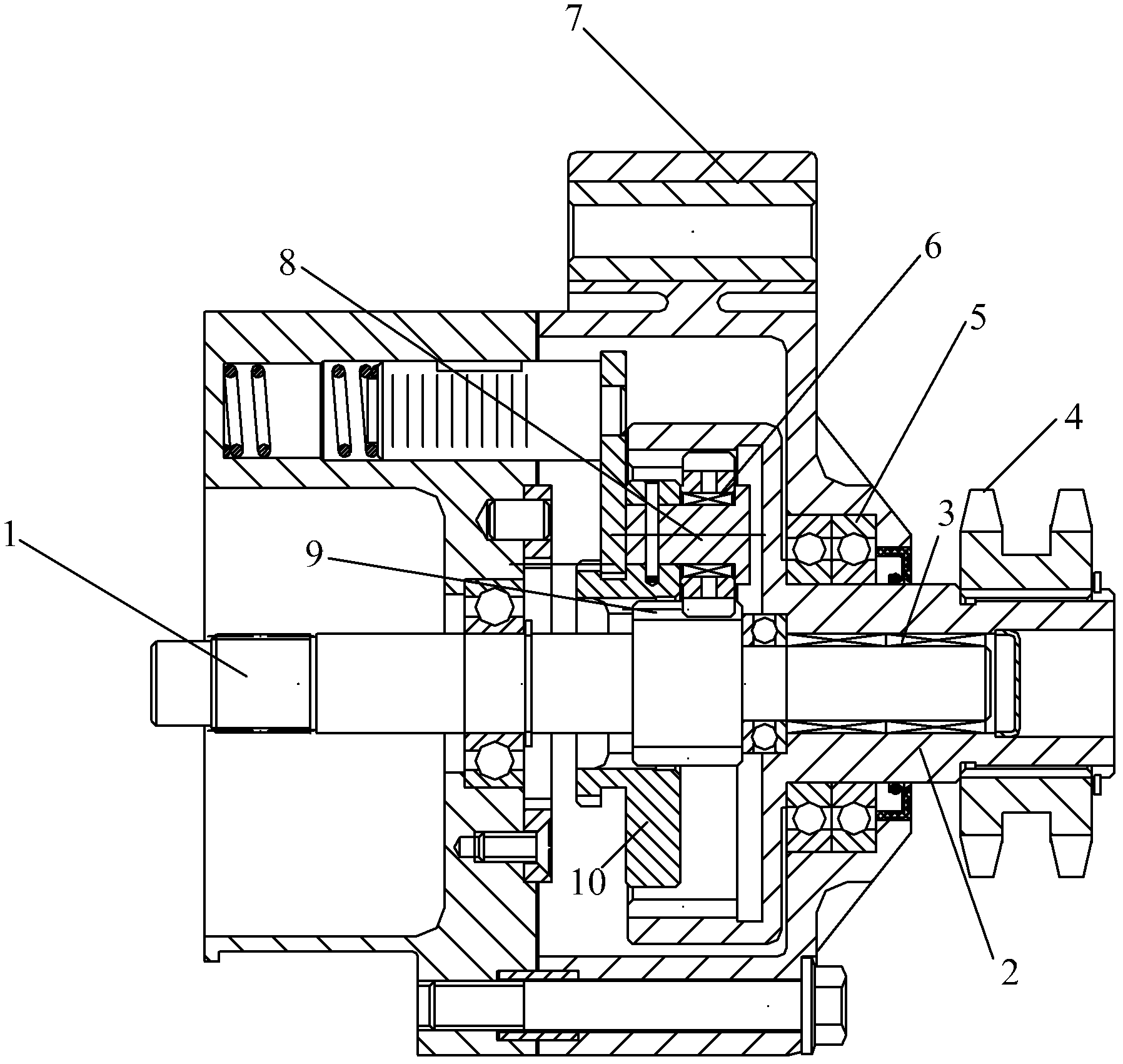

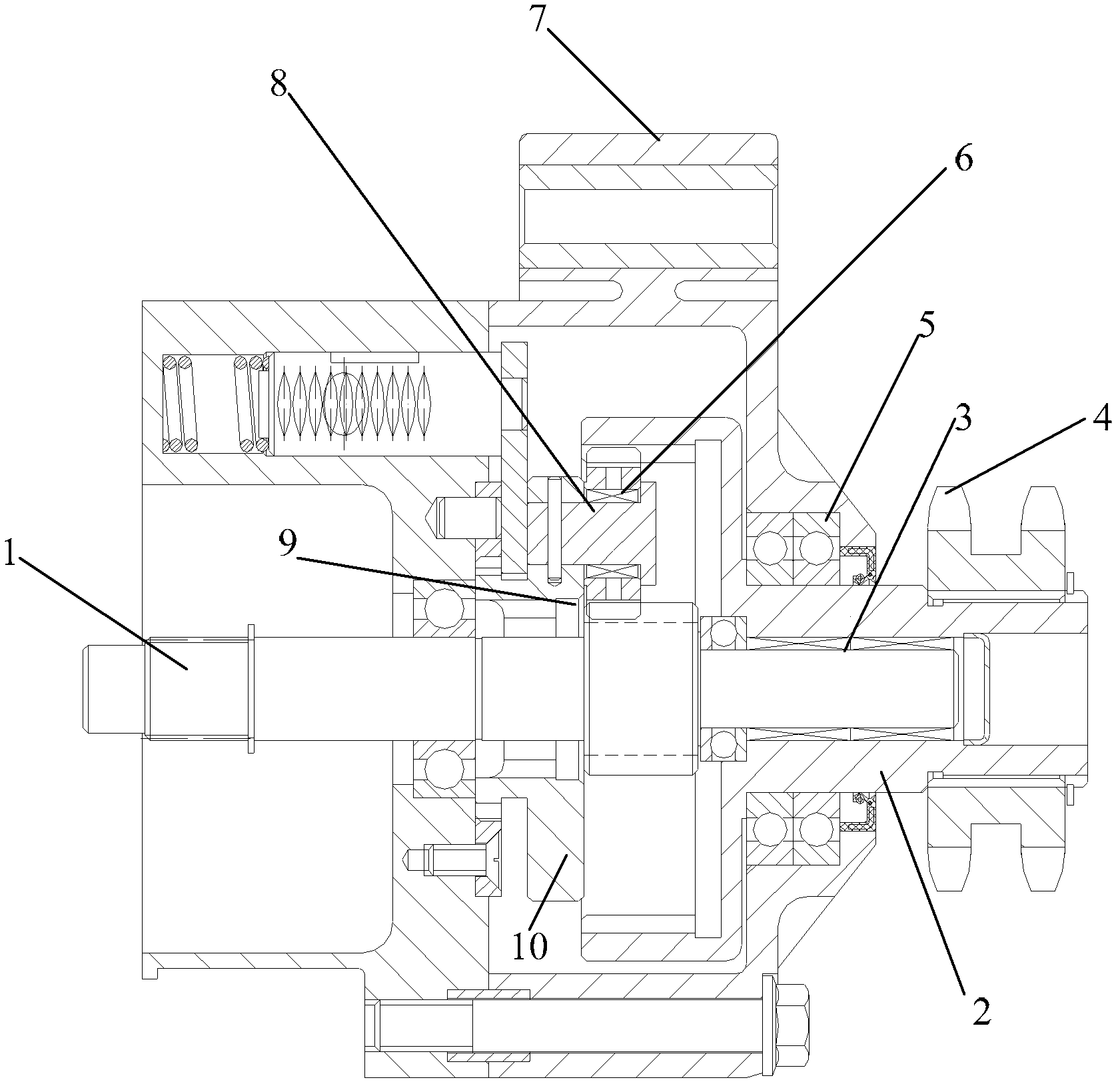

[0010] Such as figure 1 and figure 2 As shown, the interlocking planetary gear built-in reverse gear engine of the multifunctional working vehicle of the present invention includes an input shaft 1, an output shaft 2, a needle bearing 3, an output sprocket 4, a bearing 5, a planetary gear 6, a housing 7, The planetary shaft 8, the sun gear 9, the planetary gear seat 10, the input shaft 1 is connected with the output shaft 2 through the needle bearing 3, the output sprocket 4 is fixed on the output shaft 2, and the bearing 5 is arranged between the output shaft 2 and the housing 7 During this period, the planetary gear 6 meshes with the planetary shaft 8, the sun gear 9 meshes with the input shaft 1, and the planetary gear seat 10 and the sun gear 9 are fixed.

[0011] Such as figure 1 As shown, when movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com