Anti-leakage shock-proof retainer ring

An anti-leakage and shock-absorbing technology, applied in the directions of engine seals, springs, engine components, etc., can solve the problems of affecting the grinding effect, easy vibration during the rotation of the roller, adverse effects on the production results, etc., to achieve simple structure, prevent The effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

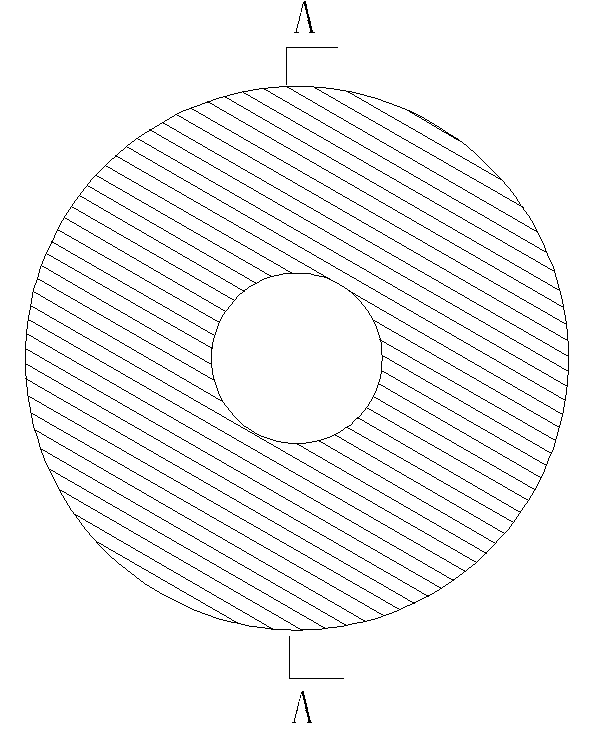

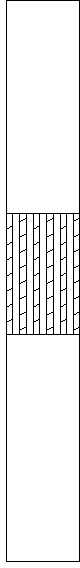

[0016] Such as figure 1 , the main body of the circular retaining ring is made of natural rubber or thermoplastic elastomer, and the center of the circular retaining ring is provided with a hole whose shape and size match the top section of the roller shaft. The inner wall of the hole is provided with an anti-skid groove, which can be figure 2 The vertical stripes shown may also be horizontal stripes or herringbone patterns (not shown in the figure), or other anti-skid patterns with anti-skid effect.

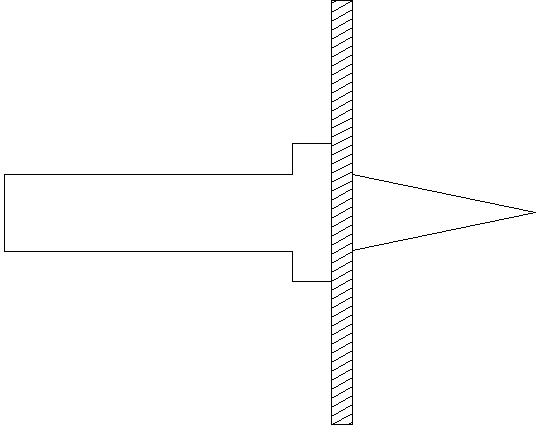

[0017] When in use, use the elasticity of the elastic material to put the anti-leakage shock-absorbing retaining ring on the top of the roller shaft to ensure that when the top of the roller shaft withstands the roller shaft, the anti-leakage shock-absorbing retaining ring can tightly hug the top of the roller shaft and It is closely attached to the side of the roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com