Coal gas flow measuring method based on heat value measurement

A technology of gas flow and measurement method, which is applied in the application of thermal effect to detect fluid flow and other directions, to achieve accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

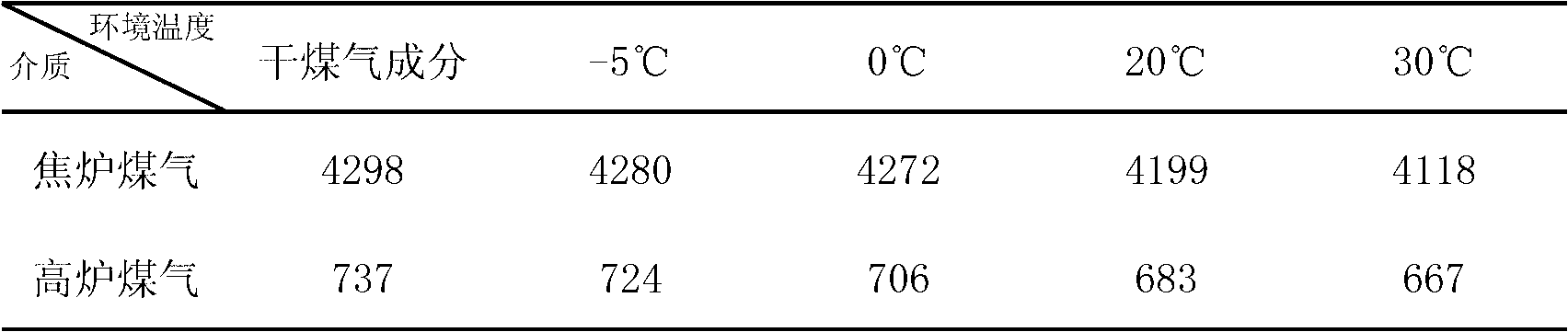

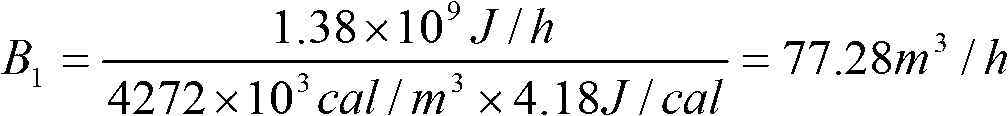

[0033] Take the design technical parameters of a heating furnace in a factory as an example, and calculate the gas consumption under the ambient temperature in winter and summer respectively under the condition that the heating furnace has not been modified. Furnace output of the heating furnace (cold charge rating): 100t / h, billet size: 150*150*12000, billet entering furnace temperature 30°C, billet heating temperature: 1150°C, unit fuel consumption (cold charge): 290*4.18kJ / kg. Fuel type: Calculated based on the above coke oven gas composition. Before the calorific value calculation was implemented, the measured hourly consumption values of coke oven gas in winter and summer in the plant were respectively: the hourly meter measured value in winter was 6865m 3 / h or so, the measured value of the hour meter in summer is 7042m 3 / h, from the results, the hourly consumption in winter is less than the hourly consumption in summer, but from the perspective of heat, the hourly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com