Rolling bearing vibration signal characteristic extracting and analyzing method under early fault state

A vibration signal, early failure technology, applied in the measurement of vibration, mechanical bearing testing, vibration measurement in solids, etc., can solve the problems of large external interference, affect objectivity, difficult to effectively separate signals, etc., to suppress noise interference and The effect of affecting and suppressing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

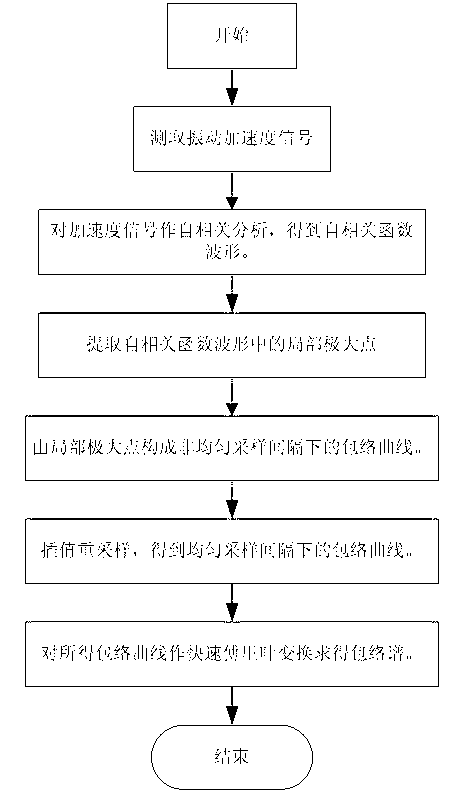

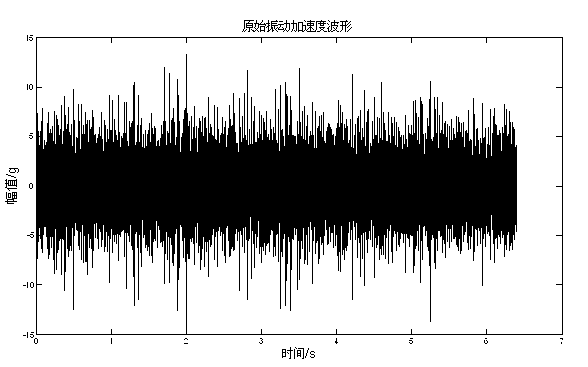

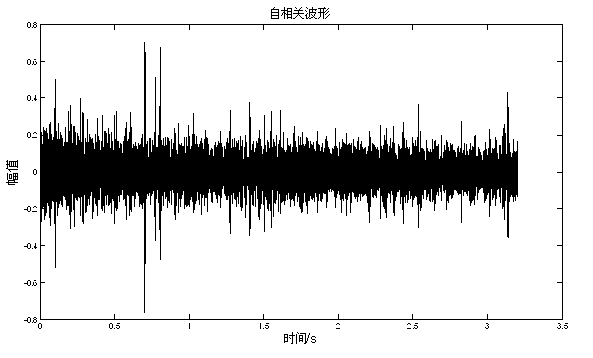

[0033] This embodiment takes the measured vibration acceleration signal of a motor as an example to analyze the vibration characteristic signal of the rolling bearing under the early weak fault state, as shown in figure 1 As shown, it specifically includes the following steps:

[0034] (1) Install the vibration acceleration sensor and use the vibration acceleration sensor to measure the vibration signal of the bearing seat. When installing the vibration acceleration sensor, fix the vibration acceleration sensor in the vertical or horizontal direction of the bearing seat; The sensor needs to be fixed on the bearing seat by connecting screws or a strong magnetic base; the vibration signal is input into the vibration testing instrument. In order to improve the analysis accuracy of the vibration signal of the rolling bearing, considering that the failure frequency of the rolling bearing may be high, the sampling frequency when collecting the vibration signal is ≥ 20KHz; in order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com