Maintenance standby system for cooling water system of nuclear power plant

A cooling water system and backup system technology, which is applied to auxiliary equipment of nuclear power plants, nuclear power generation, nuclear engineering, etc. Operation, circuit A or circuit B cannot operate normally, etc., to shorten the maintenance cycle, improve safety and reliability, and optimize the maintenance path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

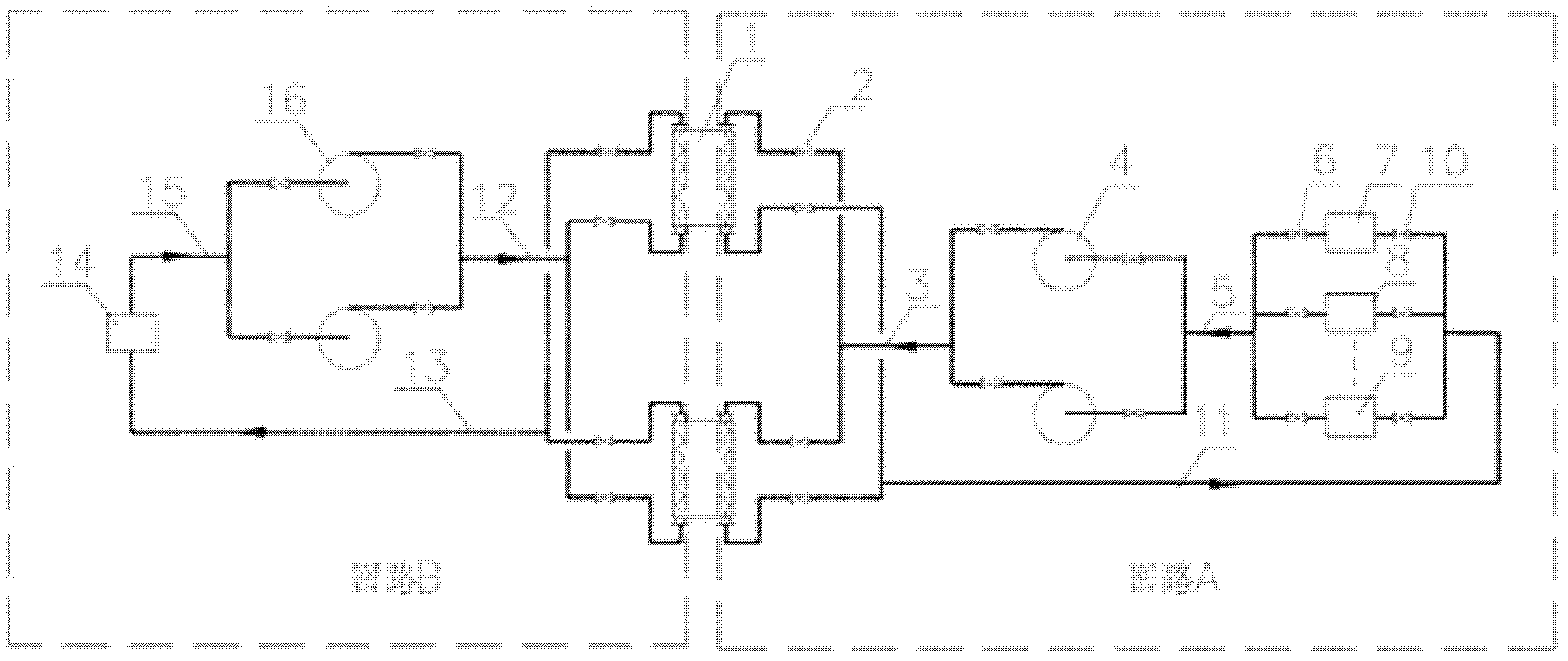

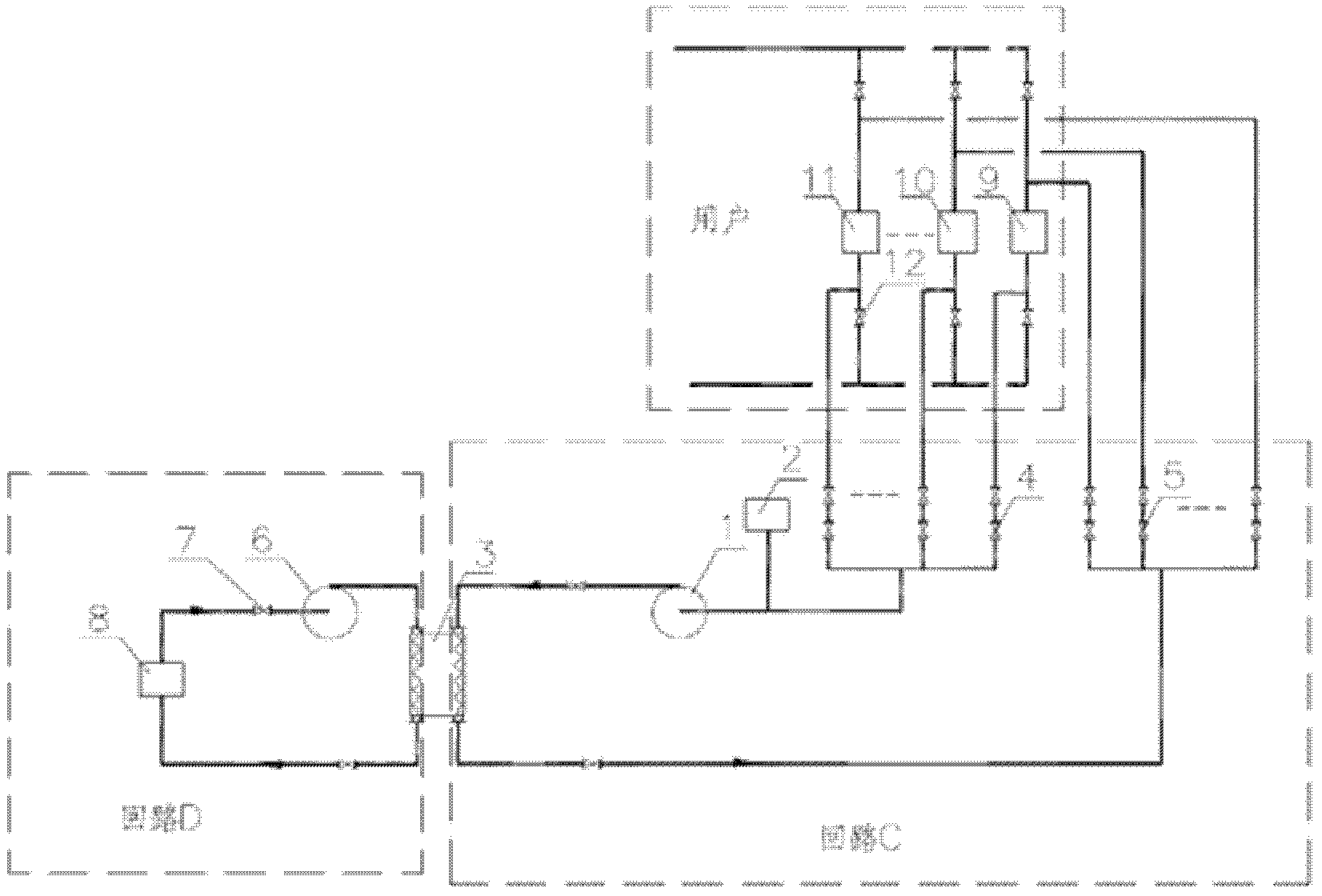

[0019] exist figure 2 The loop of the cooling water system of the nuclear power plant is not shown in the figure. In the following description, the loop of the cooling water system of the nuclear power plant is directly referred to as figure 1 The circuit shown is for illustration. but, figure 1 and figure 2 The reference signs in should be treated separately, in figure 1 and figure 2 The same reference numbers do not necessarily identify the same components.

[0020] Such as figure 2 As shown, the maintenance backup system is composed of loop C (third loop) and loop D (fourth loop). Loop C will supply cooling water system users 9, 10, and 11 (of loop A or loop B) that must supply water when the reactor is shut down for maintenance. The heat of the user) is transferred to the circuit D through the intermediate heat exchanger 3, and the circuit D releases the heat to the final heat sink 8 (such as the atmosphere or the sea, a large river, etc.). Loop C is a closed lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com