Battery capacity grading and forming system

A battery and capacity separation technology, which is applied in secondary battery manufacturing, battery circuit devices, current collectors, etc., can solve the problems of high cost, large volume, and heavy weight of power frequency transformers, and achieve low cost, small volume, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

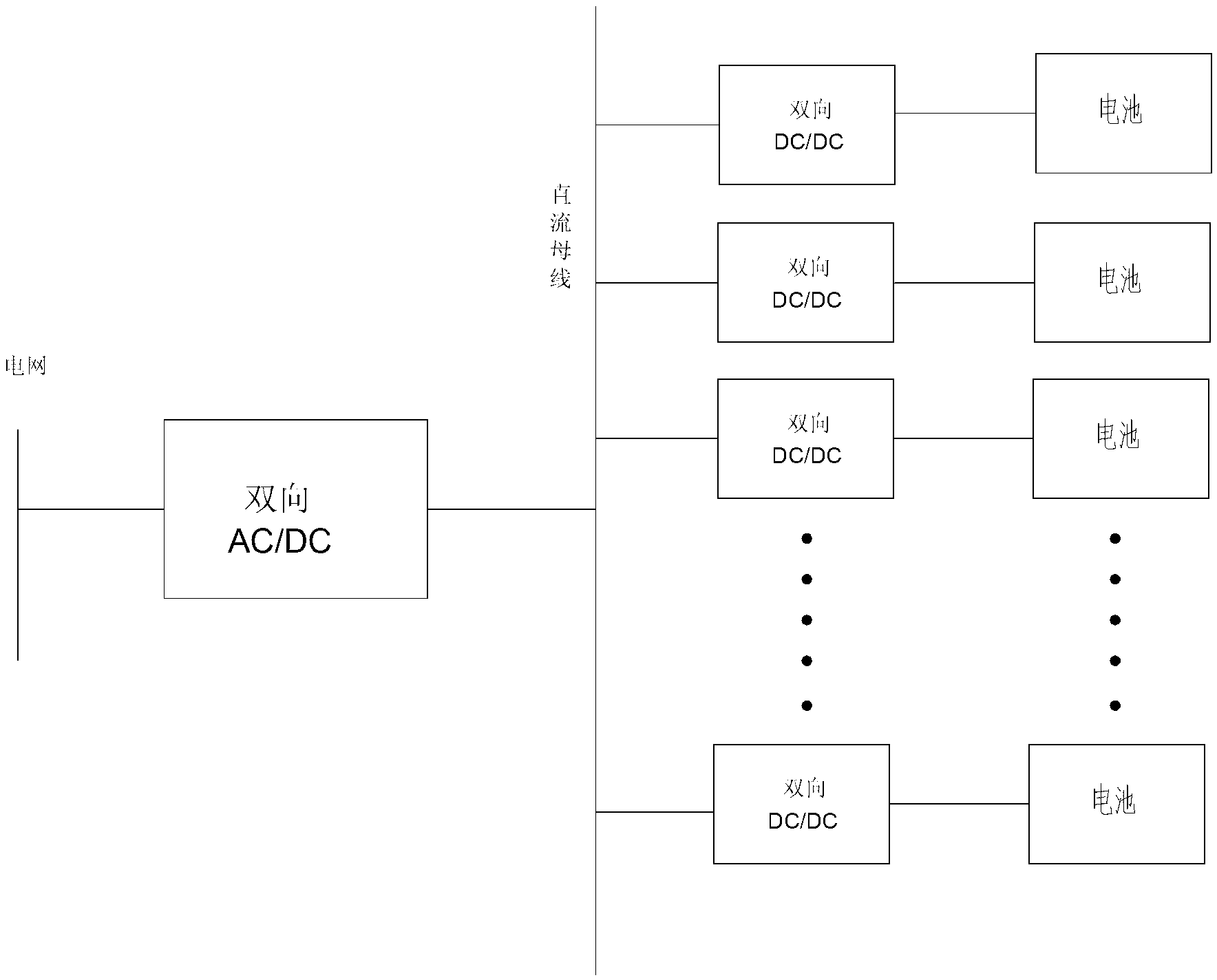

Method used

Image

Examples

Embodiment 2

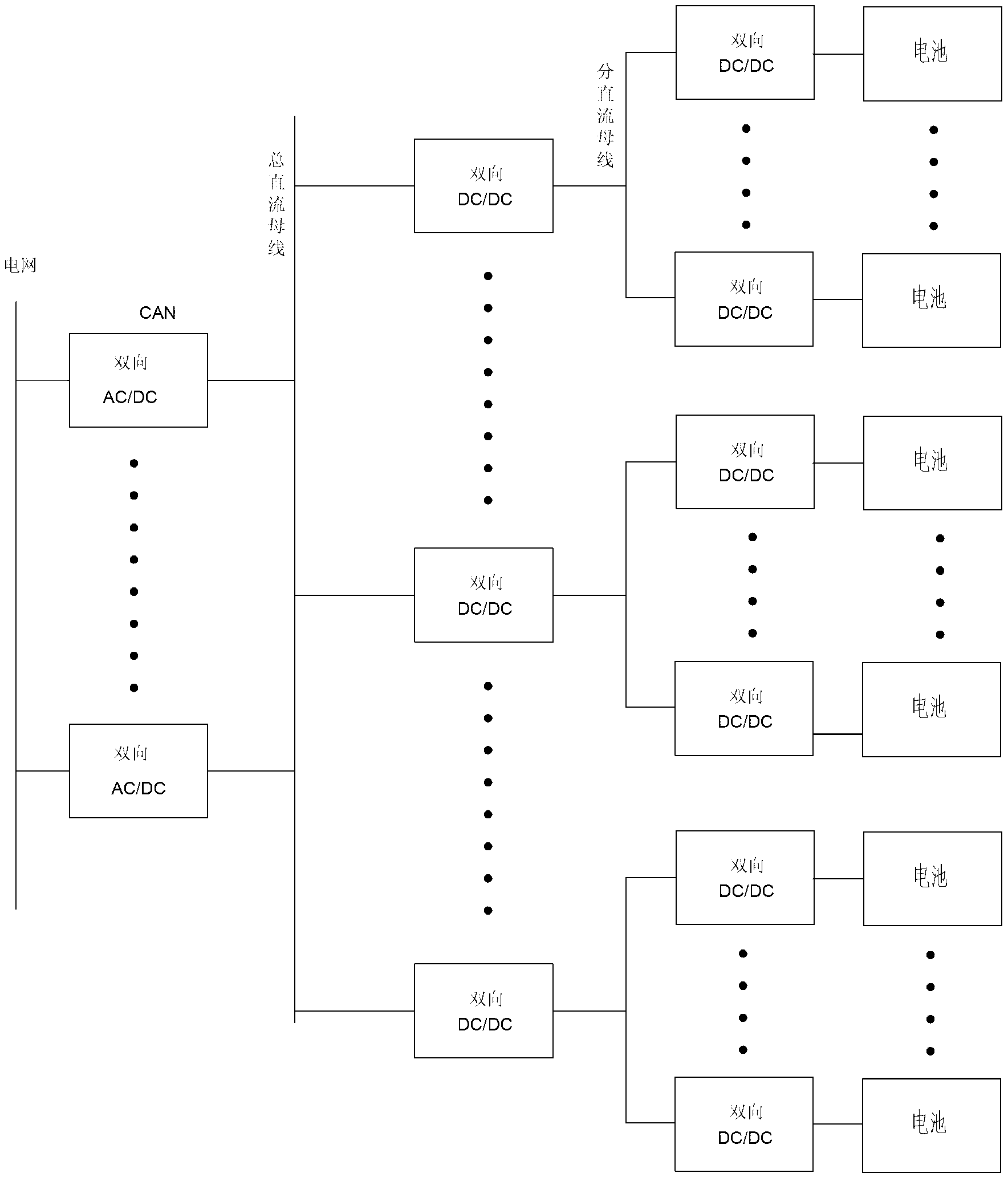

[0030] Embodiment 2 On the basis of Embodiment 1, in order to achieve energy sharing with higher efficiency, non-isolated DC / DC bidirectional converters can be grouped, such as each group is connected to 512 batteries, and there are many groups of such conversions in the system The converter groups are all connected to the first-level public DC bus (total DC bus), and controlled by software settings, so that the batteries of some converter groups work in the charging state, and the batteries of other converter groups work in the discharging state, so that the energy It can be shared on the first-level public DC bus. If the energy on the first-level public DC bus is insufficient, the AC / DC high-frequency isolated bidirectional converter will absorb energy from the grid. If the DC bus has too much energy, it will The AC / DC high-frequency isolated bidirectional converter discharges to the grid. At this time, the energy processed by the isolated bidirectional converter is not the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com