Switch device

A switchgear and ventilation device technology, which is applied in the direction of switchgear, switchgear components, substation/switchgear cooling/ventilation, etc., can solve the problems of component damage, limited air intake, inability to cool busbar room and cable room, etc. Achieve the effect of compact structure and improved cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

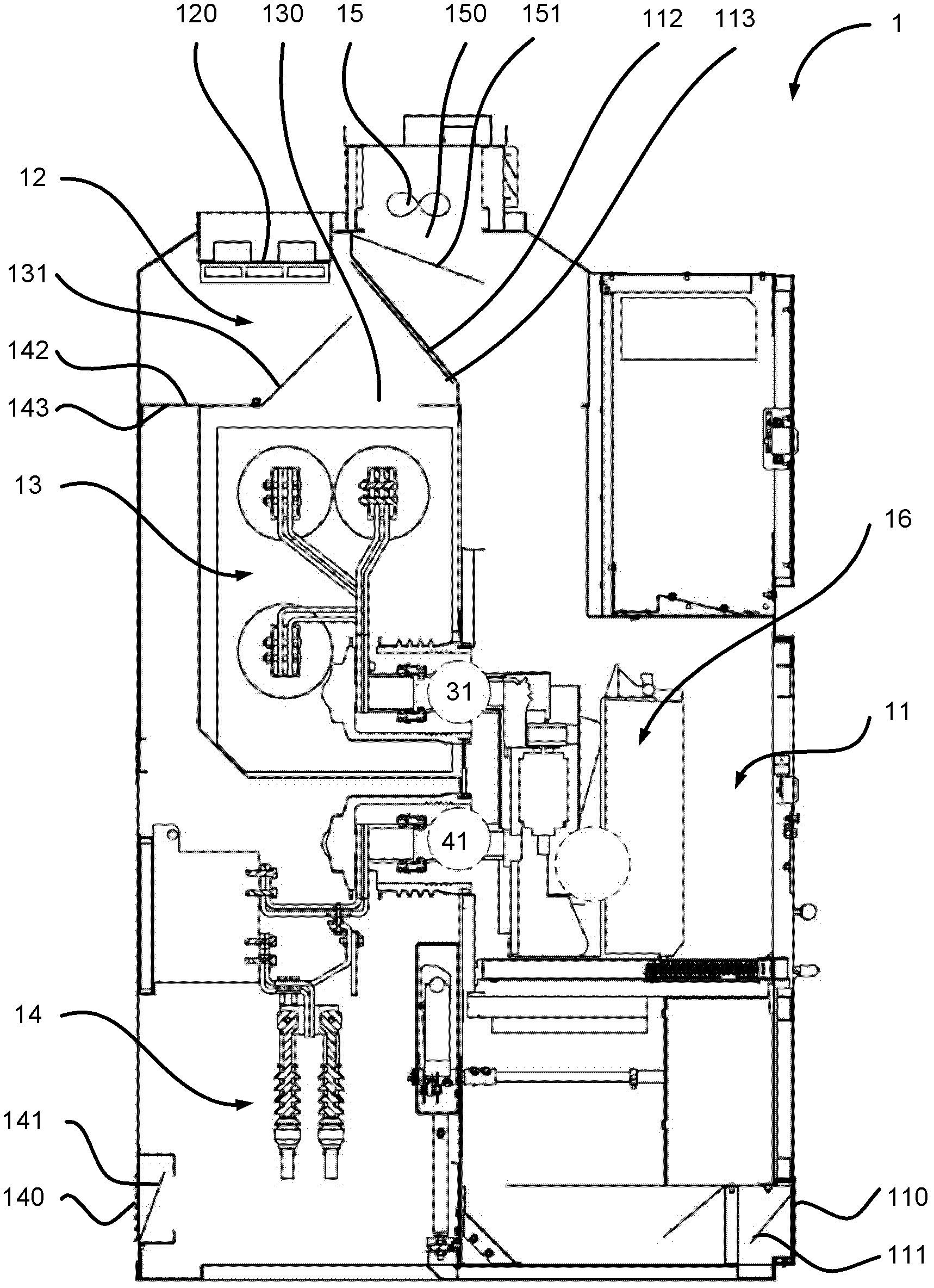

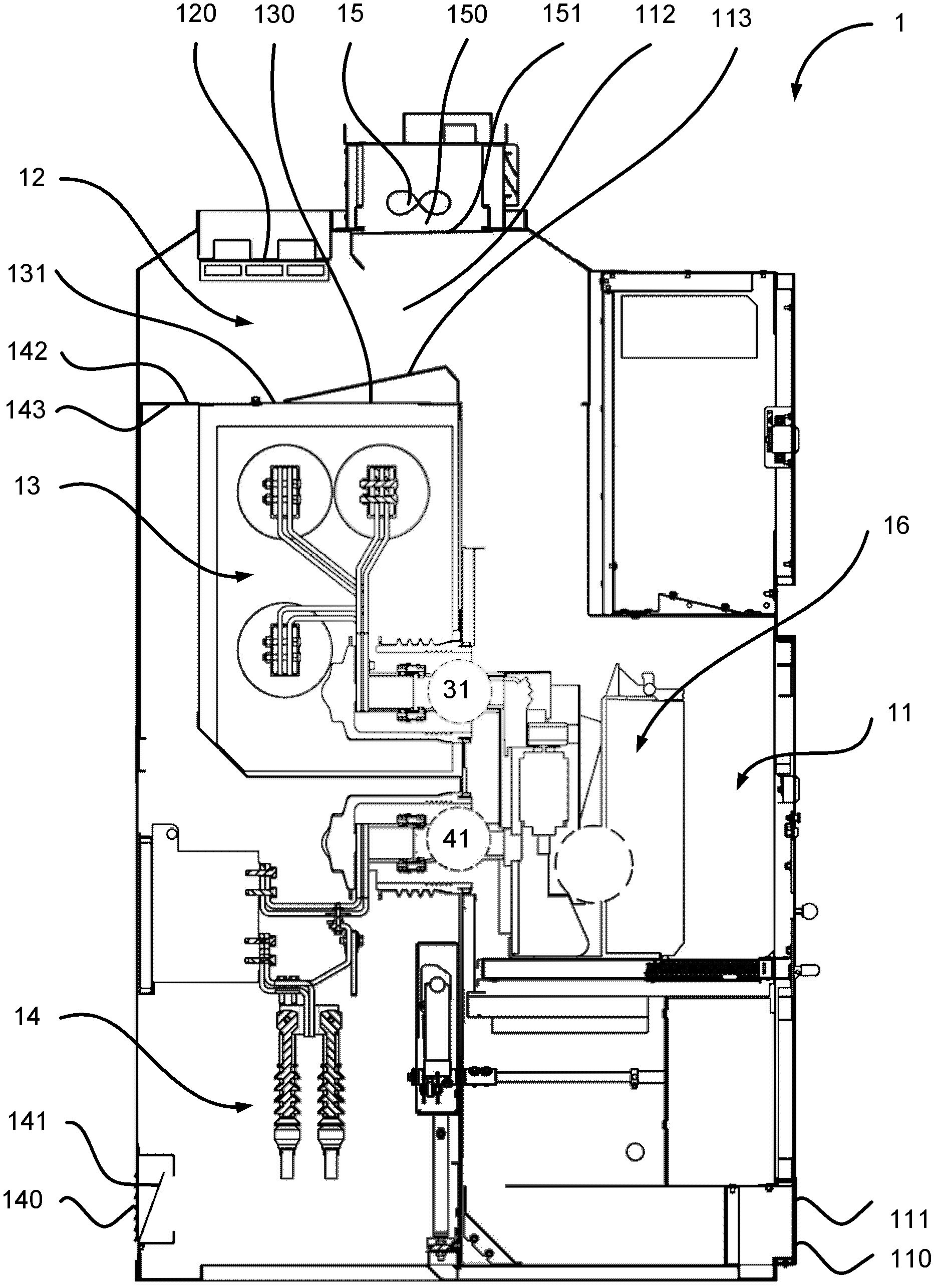

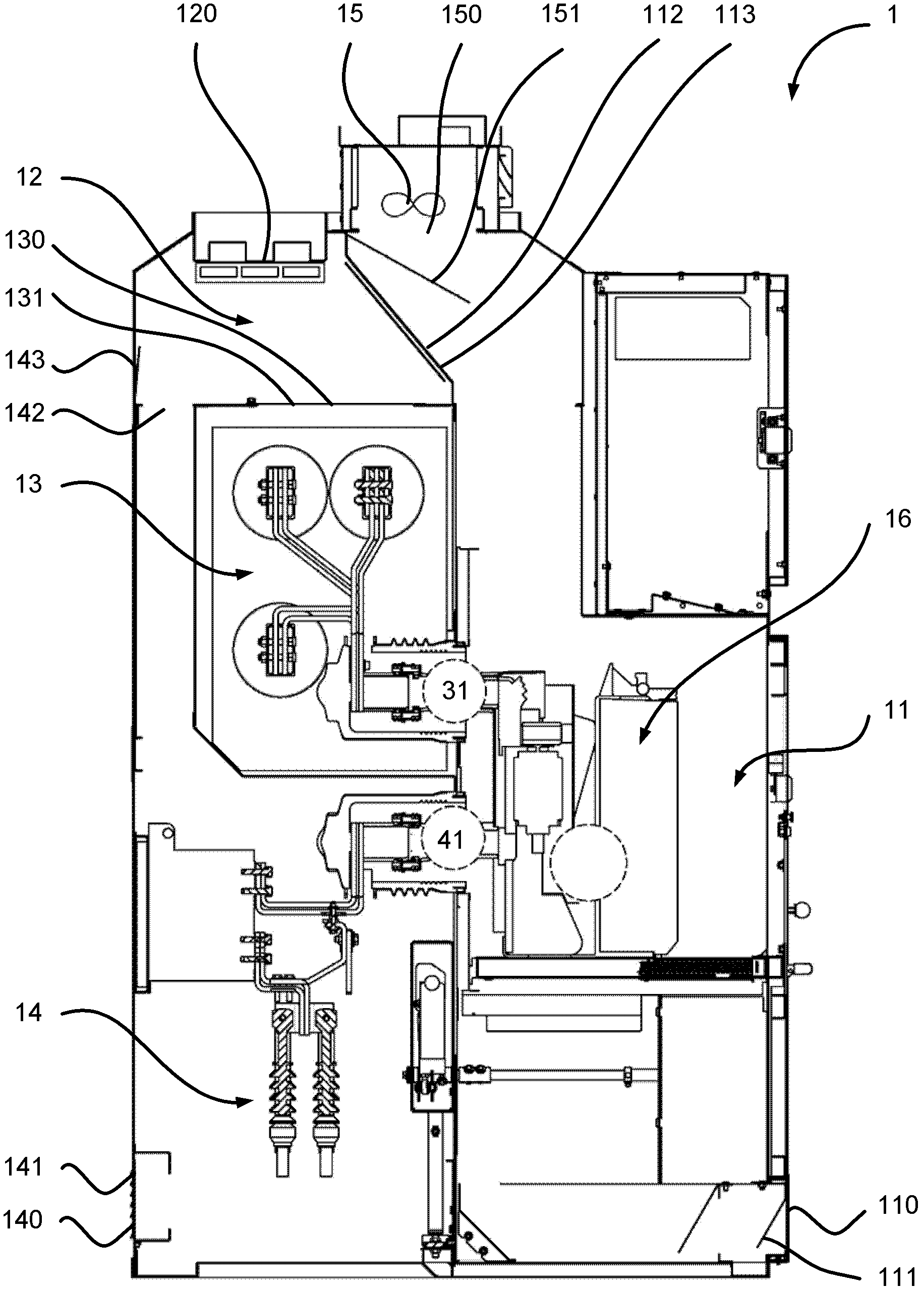

[0036] According to one embodiment of the present invention, figure 1 The switchgear 1 is in a normal operating state, wherein the handcart compartment 11 as the first compartment is adjacent to the cable compartment 14 as the second compartment and the busbar compartment 13 as the third compartment, and is adjacent to the cable compartment 14 and Between the bus compartments 13 there are respectively an interface 41 as a first interface and an interface 31 as a second interface. The handcart room 11 includes an air inlet 110 and an air outlet 150 as the first air inlet, and the ventilation device 15 is installed at the air outlet 150, wherein the air inlet 110 is preferably located on the front of the switchgear 1, and the air inlet 140 is preferably is located at the back of the switchgear 1 , while the air outlet 150 is preferably located at the top of the switchgear 1 . The cable compartment 14 includes an air inlet 140 as a second air inlet, while the busbar compartment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com