Method for electrically disconnecting or connecting disconnector with drainage wire between buses

A technology of isolating switches and drain wires, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as misoperation accidents, complicated procedures, and increased safety risks of operating personnel, so as to ensure safe operation, ensure reliability, eliminate defects or hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

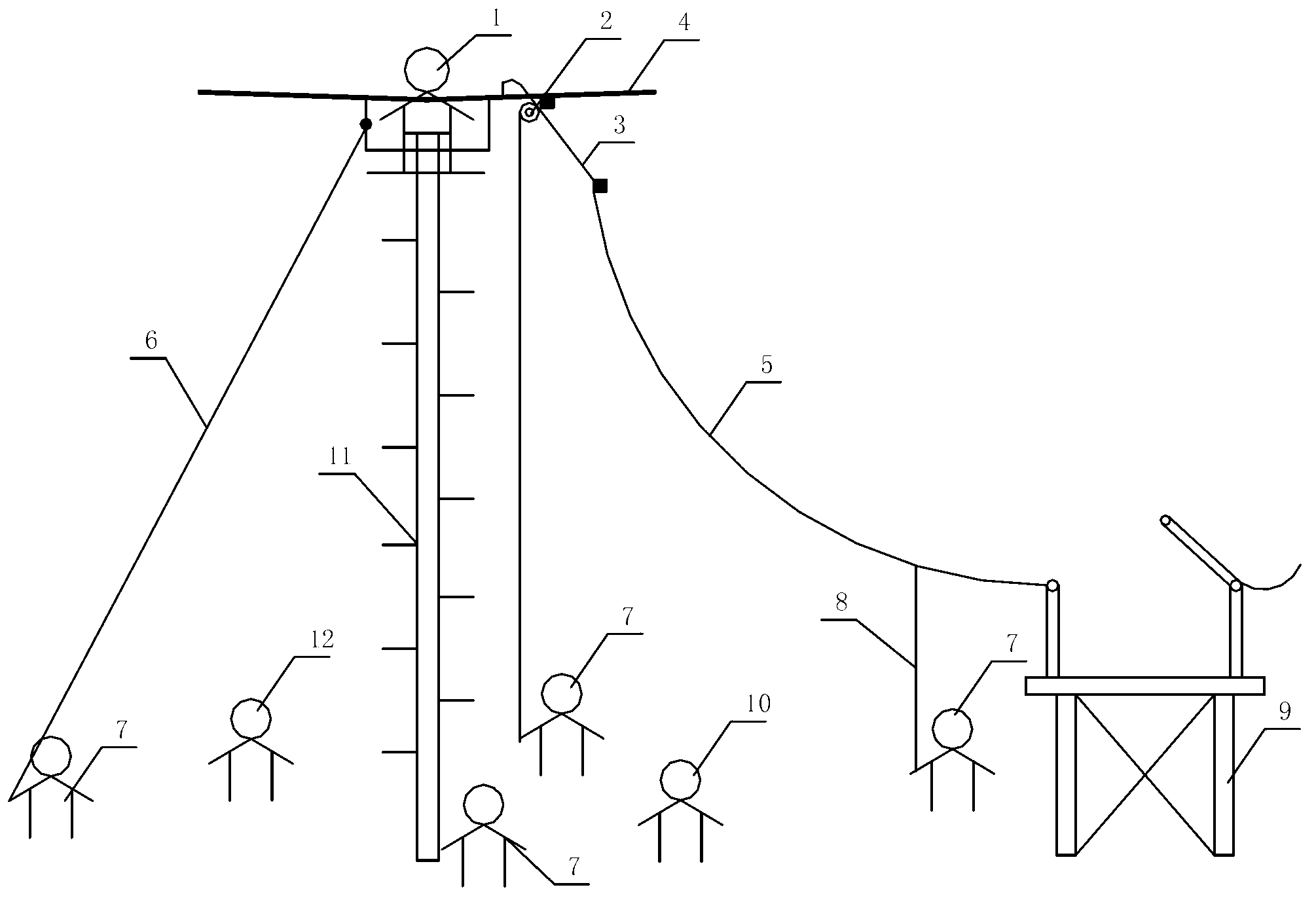

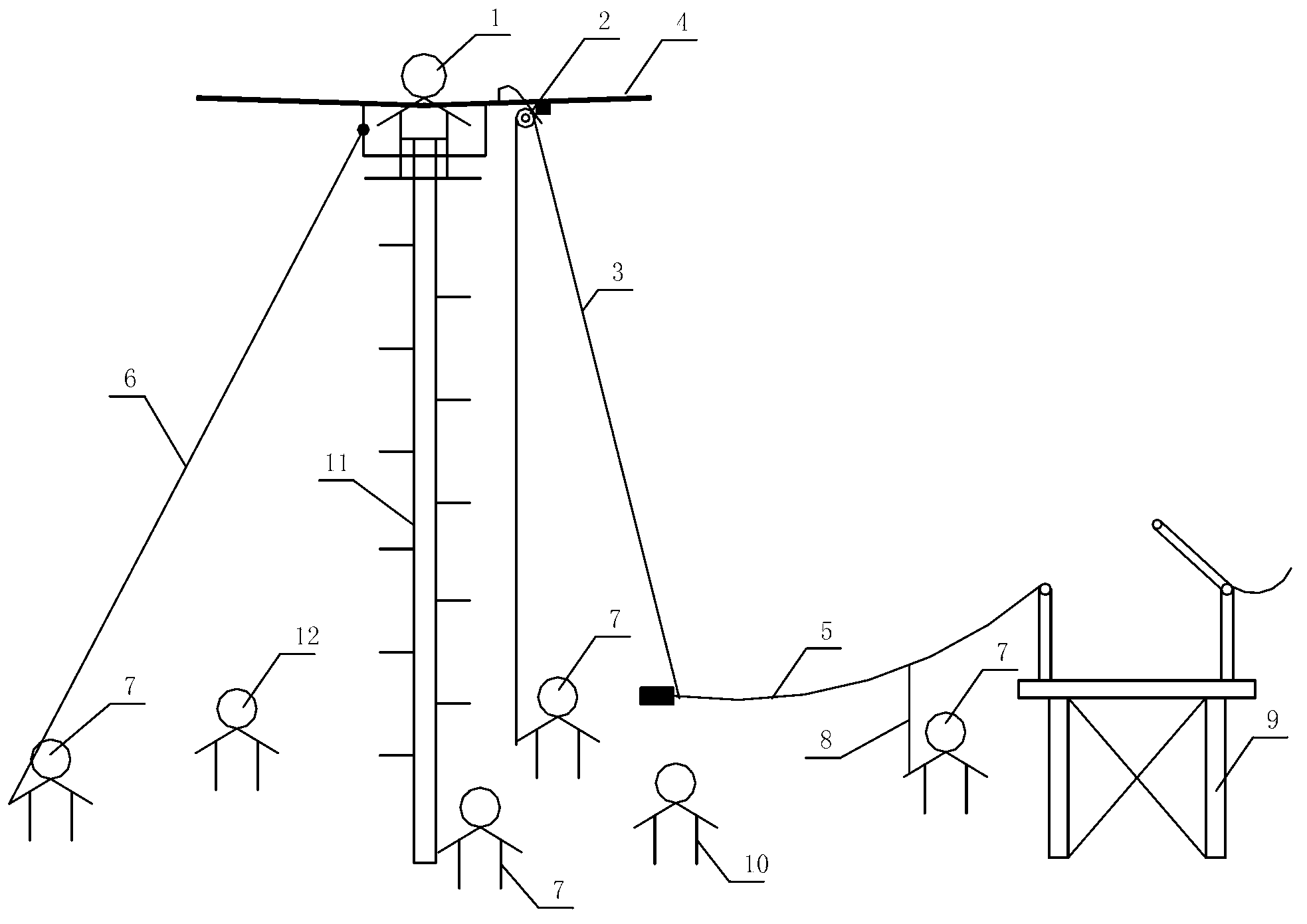

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0030] The method of disconnecting and connecting the isolating switch to the drain line between the busbars in the present invention is that the equipotential electrician 1 lifts the insulating hanging ladder 11 to the busbar 4, adopts the equipotential method to work, and the ground personnel 7 use the arc-extinguishing tackle 2 and the drain line The traction rope 3 and the insulating support rod 8 realize the disconnection and connection of the drain wire 5, which specifically includes a live disconnection step and a live connection step, wherein:

[0031] one sight figure 1 , the steps of live disconnection are as follows:

[0032] 1) The equipotential electrician 1 puts on the shielding suit, assembles the insulating hanging ladder 11 on the ground, and uses an insulation resistance meter to test the insulation tools in sections. The resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dc resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com