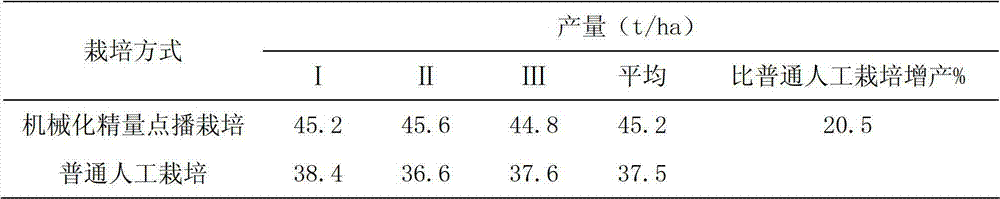

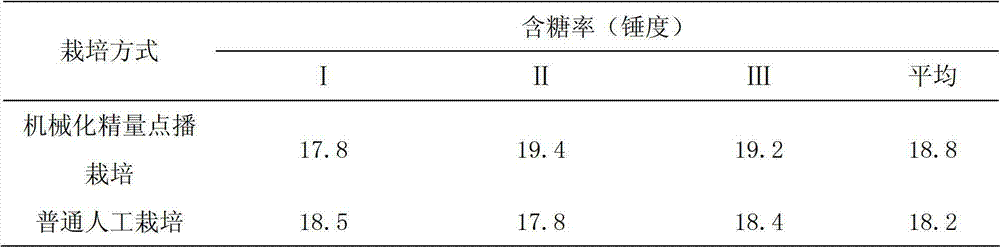

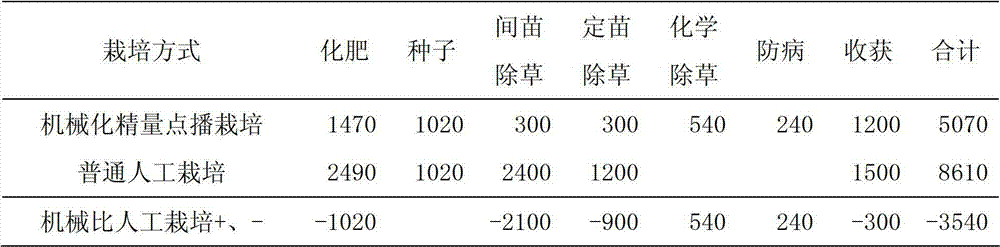

Low-cost beet mechanical precision spaced sowing cultivation method

A cultivation method and low-cost technology are applied to the cultivation field of sugar beet, can solve the problems of high production cost, low yield of sugar beet, low benefit and the like, and achieve the effects of saving chemical fertilizer, reducing the harm of flea beetle, and early emergence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific implementation mode one: the low-cost sugar beet mechanization precision on-demand cultivation method of this implementation mode is realized according to the following steps:

[0017] 1. Subsoiling cultivation: choose beet fields that have not been planted with beets for more than 4 years on flat, well-drained, fertile flats or flat lands, and carry out autumn land preparation on the land, subsoiling ridges, and the subsoiling standard is 30 to 35 cm , planted with a narrow row spacing of 50-65 cm;

[0018] 2. Formula deep fertilization: Cooperate with subsoiling and ridging, apply chemical fertilizers as base fertilizer at one time, the fertilization depth is 20-25 cm, and the amount of fertilizer per hectare is N 120-140 kg, P 2 o 5 60 ~ 80 kg, K 2 O 40-60 kg;

[0019] 3. Accurate on-demand sowing: the time is from April 20th to 30th, when the ground temperature of the 5 cm soil layer is stable at 5°C, and the external ambient temperature is stable at 10...

specific Embodiment approach 2

[0028] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is that the amount of fertilization per hectare in step two is N125~135 kg, P 2 o 5 65 ~ 75 kg, K 2 O 45-50 kg. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0029] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one is that the fertilization rate per hectare of step two is N130 kilograms, P 2 o 5 70 kg, K 2 O 50 kg. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com