Individual wheel suspension with automatic camber adaptation

An independent wheel and wheel suspension technology, applied in the direction of elastic suspension, suspension, vehicle components, etc., can solve the deterioration of vehicle handling performance, failure to reach the maximum possible value of tire contact surface or cornering force, adverse effects of camber angle, etc. problems, to achieve the effect of simple adjustability, reduced force transmission path, and simplified design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

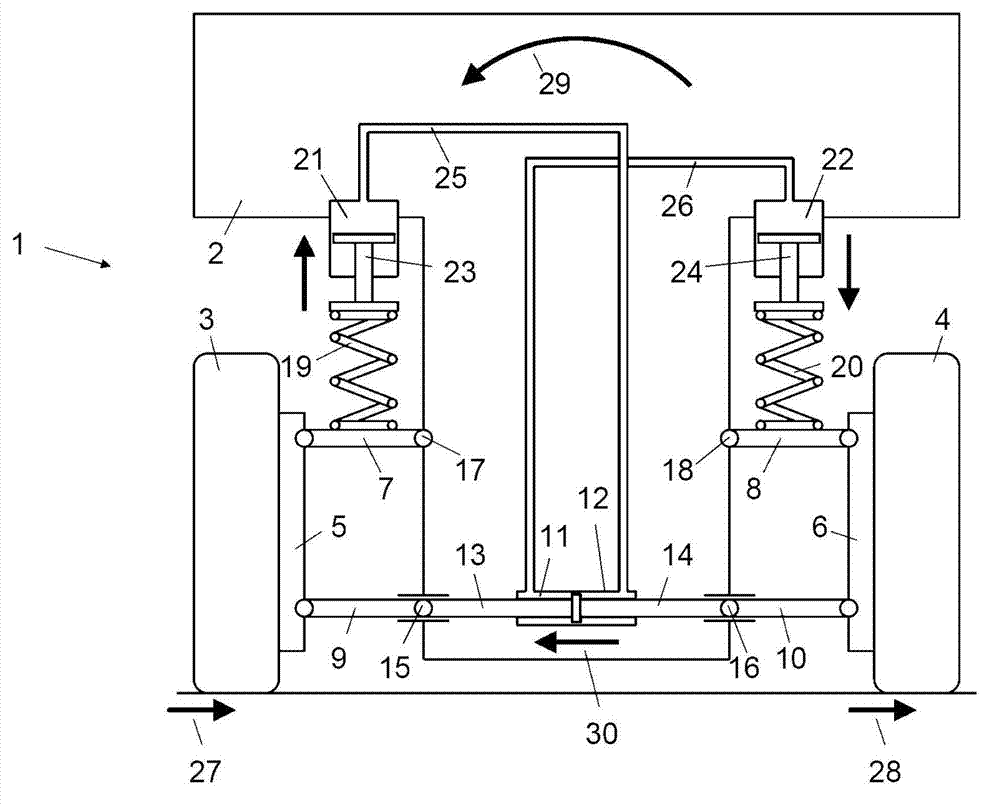

[0061] figure 1 A schematic rear view of a wheel suspension 1 according to the invention in a vehicle, in particular a motor vehicle, is shown. The description of other spring and / or damper elements, such as suspension struts, has been omitted for the sake of clarity, since said elements are known to a person skilled in the art from the prior art and are not primarily relevant to the invention. In addition, in figure 1 In the illustration of , the left vehicle side corresponds to the first vehicle side, and the right vehicle side corresponds to the second vehicle side.

[0062] figure 1 The vehicle shown comprises a body 2 and left and right wheel or wheel rim arrangements 3 and 4, which are passed through left and right wheel brackets 5, 6 and left and right upper transverse links 7, 8 and Left and right lower transverse links 9 , 10 are connected to the body 2 . In particular, the left and right transverse links 9 and 10 are connected at the side of the vehicle to an act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com