Frame of multifunctional special car

A special vehicle and multi-functional technology, applied in the field of vehicles, can solve the problems of small torsional rigidity, unsatisfactory requirements, high height of driver's seat and floor, etc., to improve torsional and bending rigidity, adapt to structure and performance requirements, and facilitate The effect of getting on and off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

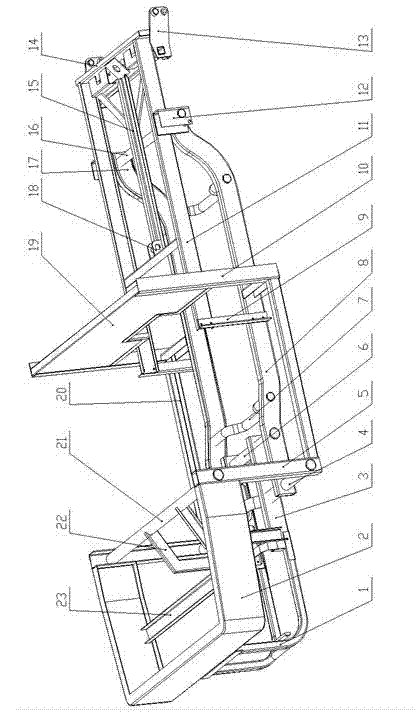

[0014] exist figure 1 Among them, the front upper frame 2 of the present invention and the front small longitudinal beam 3 of the lower frame are connected through the front small frame 1, and the mode is bolted and detachable. The front first circular tube crossbeam 4 passes through the left and right two lower frame front small longitudinal beams 3, the left and right two lower frame longitudinal beams 8, the left and right two lower frame longitudinal beam inner reinforcing beams 17 and the left and right two front columns 5 and Welded together, the second round tubular crossbeam 6 of the lower frame passes through the left and right two lower frame front small longitudinal beams 3, the left and right two lower frame longitudinal beams 8 and the left and right two lower frame longitudinal beam inner reinforcing beams 17 and is welded on the Together, the third round tube beams 7 (two) of the lower frame pass through the left and right two lower frame longitudinal beams 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com