Guide mechanism of rope for elevator tractors

A tractor and rope technology, used in elevators, transportation and packaging, can solve problems such as car shaking, single function, and inability to check rope wear, and achieve the effect of eliminating potential safety hazards and improving functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

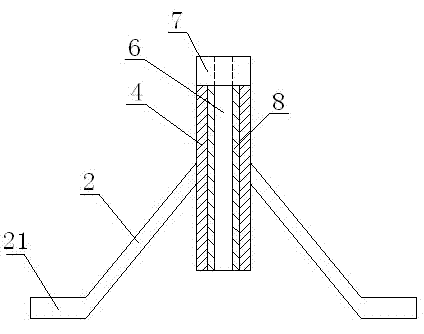

[0013] Such as figure 1 As shown, a guiding mechanism for a rope of an elevator traction machine according to the present invention includes a guiding block 4, on which there are three brackets 2 evenly spaced apart, and the brackets 2 have mounting parts 21 respectively, When in use, the bracket 2 is fixed on the top of the car through the mounting part 21. The guide block 4 has a guide hole 6 with a length of 80-100 cm for the cable to pass through. The hole wall of the guide hole 6 is pasted with rubber Layer 8, a metal surface flaw detection instrument 7 is installed on the top of the guide block 4. When in use, the metal surface flaw detection instrument 7 will detect the wear of the rope surface in real time, thereby eliminating the potential safety hazard of broken rope

[0014] In summary, the present invention can detect the wear condition of the surface of the cable, and has perfect functions.

[0015] The above descriptions are only preferred embodiments of the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com