Outside-furnace refining production method of steel used in carbon steel welding wire

A technology of solid welding wire and refining outside the furnace, which is applied in the field of steelmaking, can solve the problems of composition uniformity, steel cleanliness, and steel quality that cannot meet the requirements of use, so as to help control the temperature of molten steel and reduce nozzle blockage Risk, heat reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention can be implemented in steel mills equipped with reblowing converters, ladle bottom blowing argon process and fully protected casting conditions. Tables 1 to 4 below list key parameter examples and physical quality levels of the production process when Shougang Corporation adopts the present invention to produce steel ER50-6 for carbon steel welding wire.

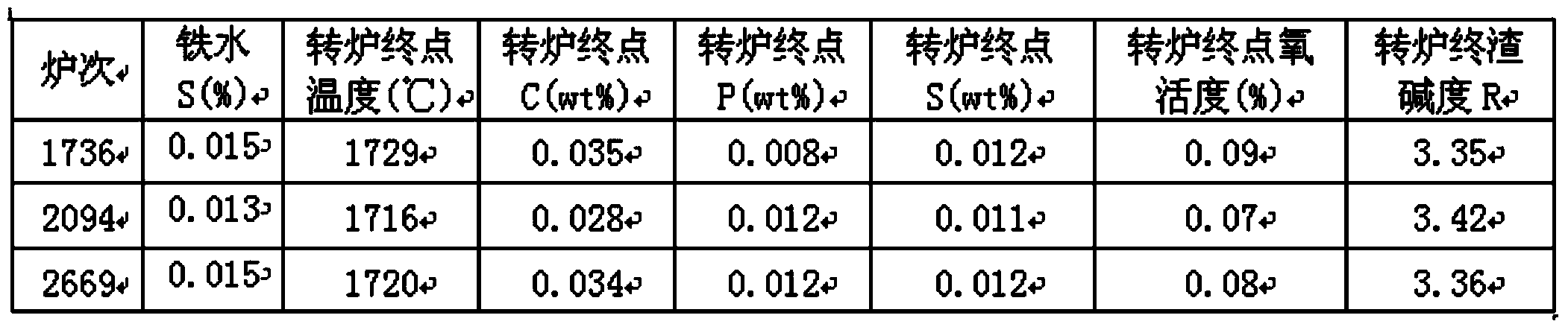

[0028] Table 1 Key parameters of combined blowing converter process

[0029]

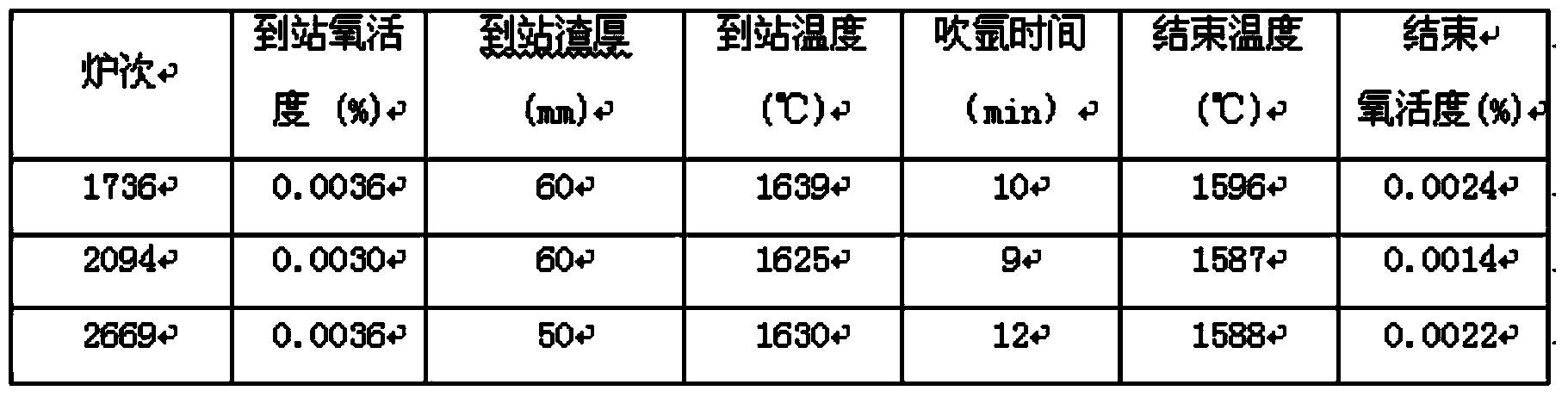

[0030] Table 2 Key parameters of refining process

[0031]

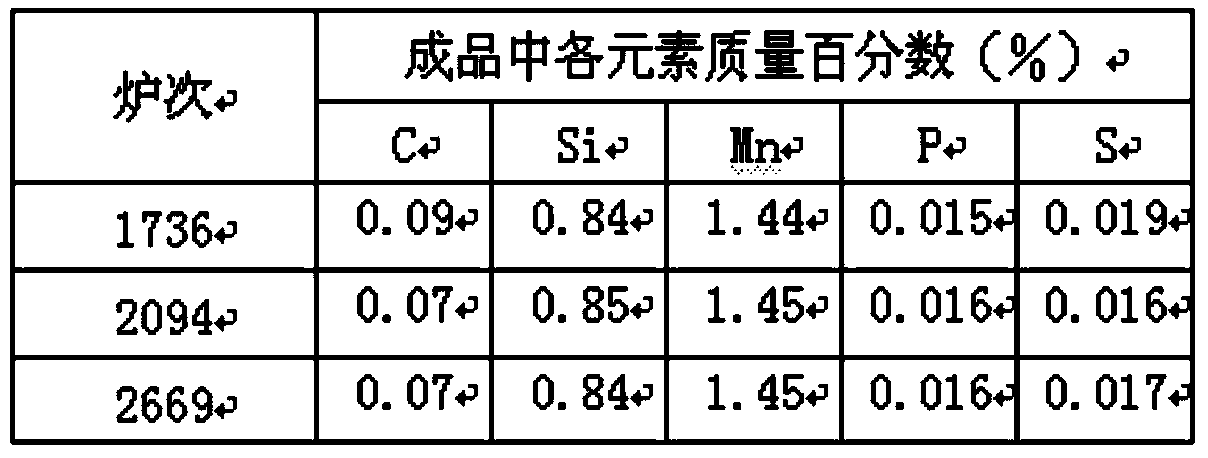

[0032] Table 3 Control level of finished product components

[0033]

[0034] Table 4 Steel cleanliness level - non-metallic inclusions

[0035]

[0036] Table 5 Steel cleanliness level - gas content

[0037] Stoves

[0038] It has been verified by production practice that the method provided by this patent can be used to successfully produce carbon steel welding wire steel, and the chemical composition, steel cleanliness level and other indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com