Insulation plate of electroplating machine

An electroplating device and insulating board technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of insulation bottom plate deformation, increase in use cost, increase in production cost, etc., and achieve the effect of reducing the speed requirement and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

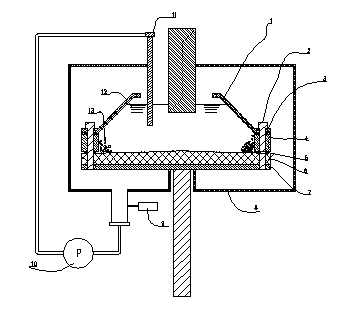

[0018] The insulating plate 6 of the present invention is a convex structure, and the inclination angle between the highest point and the lowest point of the convex surface is less than 5°. o .

[0019] The present invention will be further described below in conjunction with its working environment:

[0020] The processing container 1 of the present invention is formed by stacking the conductive plate 7 , the insulating plate 6 , the gasket 5 , the electrode ring 4 , and the upper cover 3 sequentially from the bottom, and connecting them with the conductive member 2 . When the electroplating liquid 12 needs to be discharged, the electroplating liquid 12 in the processing container 1 enters the recovery device 8 through the gap formed between the insulating plate 6 and the gasket 5, between the gasket 5 and the electrode ring 4, and starts and recovers the device 8 The connected vacuum device 9 makes a certain degree of vacuum formed in the recovery device 8 to realize the sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com