Coal-pillar-free semi-normal-position goaf-side entry retaining method

A technology of retaining roadways without coal pillars, which is applied in the direction of earthwork drilling, filling, safety devices, etc., to achieve obvious effects, reduce spans, and prevent deformation and sideslip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

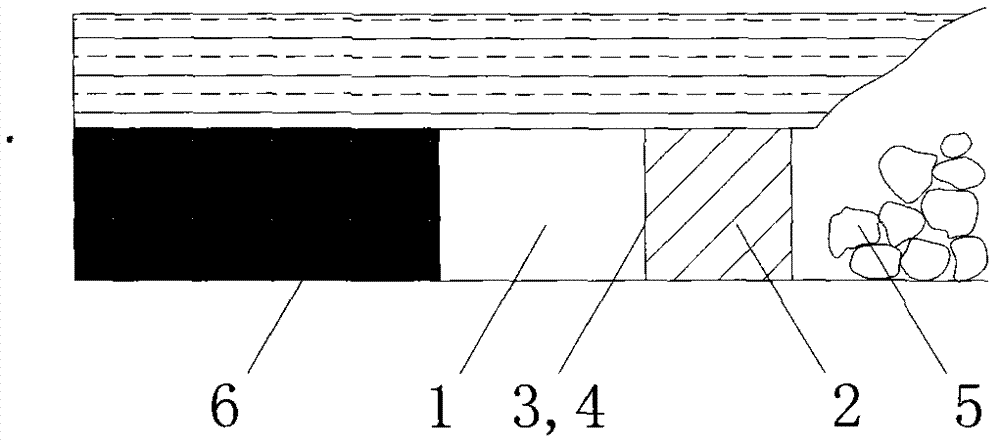

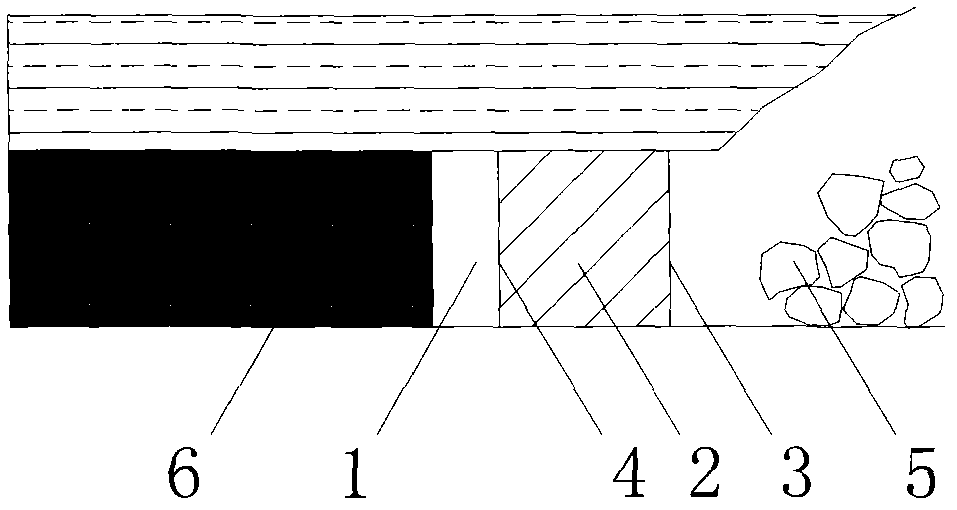

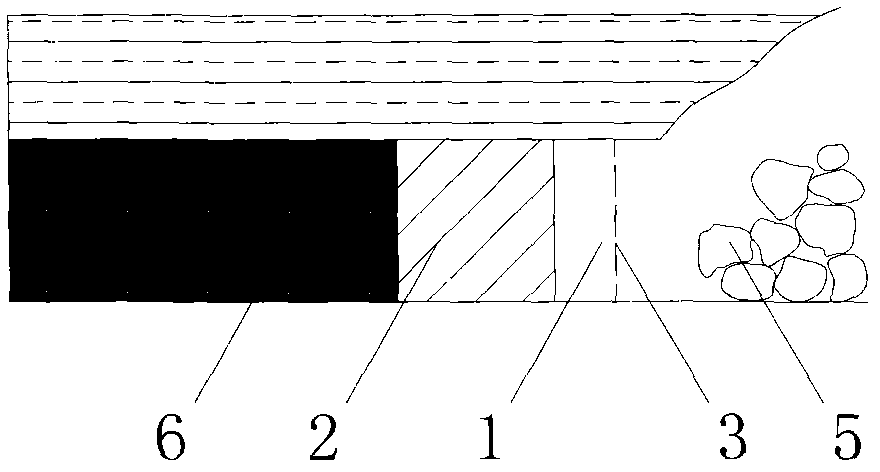

[0015] The implementation steps of a semi-in-situ gob-side entry retention method without coal pillars are as follows:

[0016] 1. Advance tearing of the side: advance the working face, tear the side on the mining side of the entry, pick out the false roof, and pre-reinforce the roof.

[0017] 2. The support moves forward: the support moves forward in sequence according to the coal mining step. When the displacement distance behind the support reaches the length of a single filling wall, the filling is performed.

[0018] 3. Support behind the frame: The roof must be supported in time every time the frame moves a step. When the roadway adopts the frame support method, the frame needs to be erected in advance.

[0019] 4. Clean up the vertical formwork: clean up the empty gangue on the bottom of the roadway at the area to be filled behind the outlet support on the working face, and fix the filling formwork at a certain distance from the mining side of the roadway. Then lay a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com