Down lamp capable of dissipating heat through convection of inner passage and outer passage

A technology of downlights and channels, which is applied in lighting and heating equipment, components of lighting devices, cooling/heating devices of lighting devices, etc., can solve problems such as poor heat dissipation, heat island effect that cannot solve local high temperature heat dissipation, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

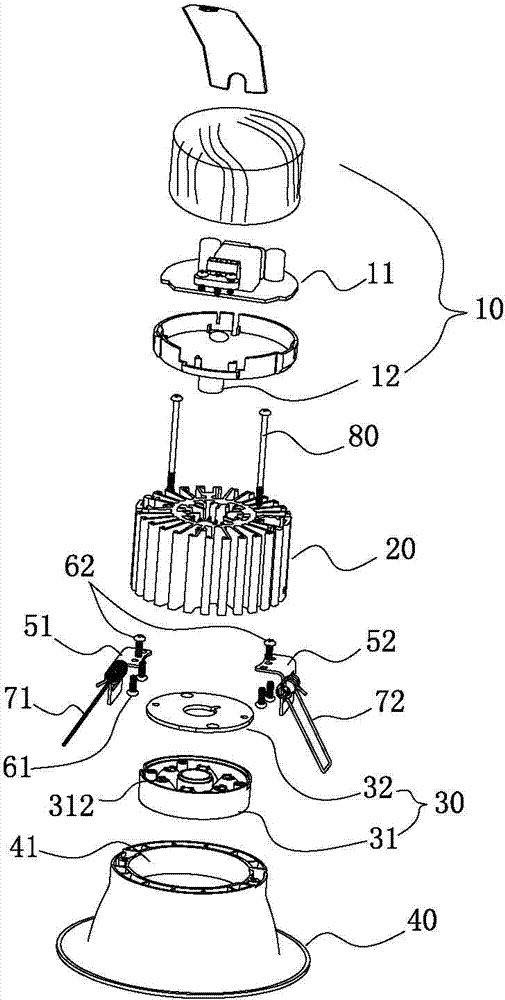

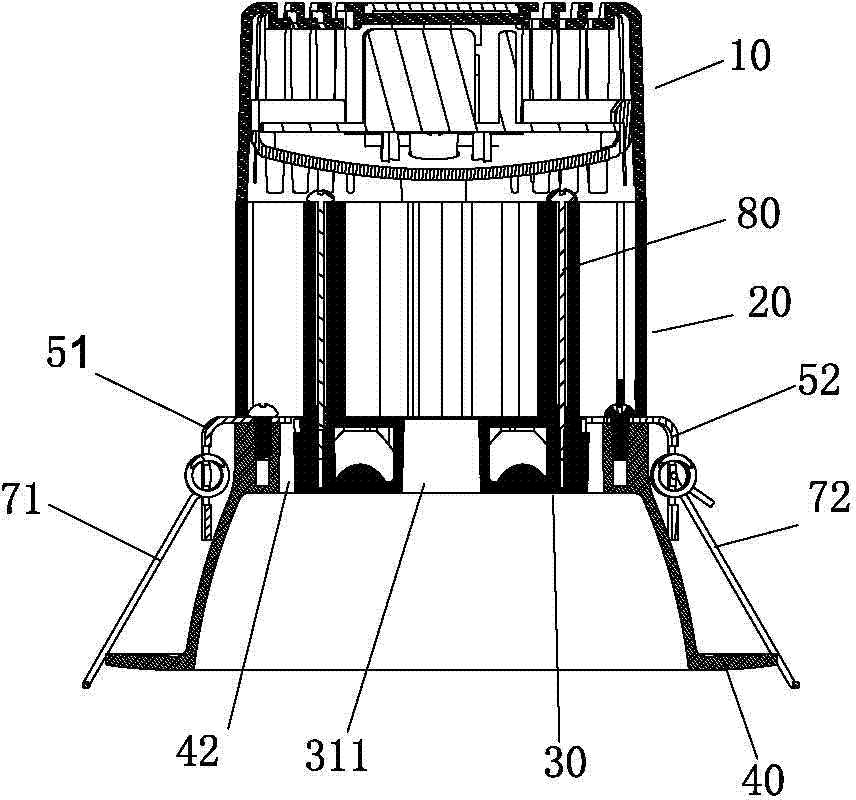

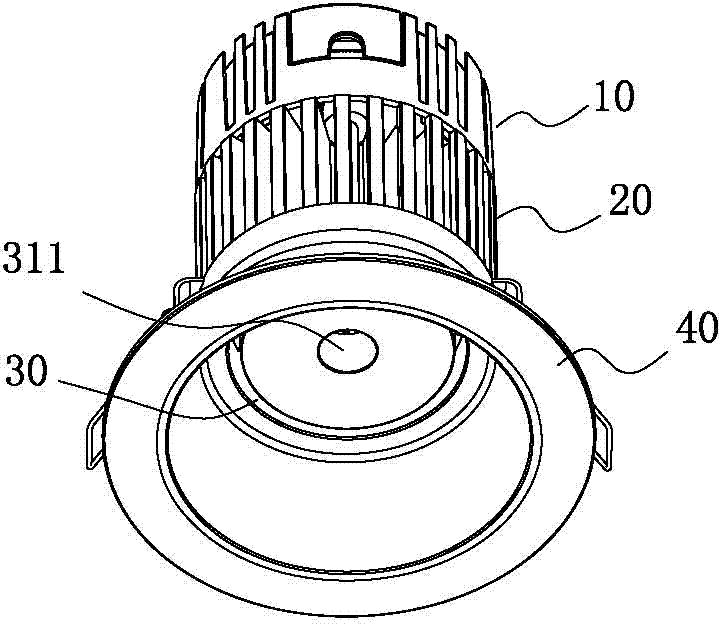

[0027] The following will be combined with Figure 1-7 An example for further details:

[0028] A downlight with convection heat dissipation through internal and external channels in the embodiment includes: an electrical module 10, a heat sink 20, an optical engine 30 and a lampshade 40, and the electrical module 10 includes an LED control circuit board 11 with an external power supply.

[0029] The radiator 20 is mainly composed of a cylinder cavity 21 and a number of heat dissipation ribs 22 connected to the outside of the cylinder cavity 21 from top to bottom at intervals. ; An open external convection heat dissipation channel 24 is formed between every two adjacent heat dissipation fins 22 .

[0030] The optical engine 30 includes a module lens 31, an aluminum substrate 32 and several LEDs 33, the center of the module lens 31 has a module lens through hole 311 for convection heat dissipation, and the center of the aluminum substrate 32 has an aluminum substrate for conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com