Illuminator

A lighting device and light source technology, applied in the field of lighting, can solve the problems of poor heat dissipation effect of the lighting device, and achieve the effects of ensuring service life, easy assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

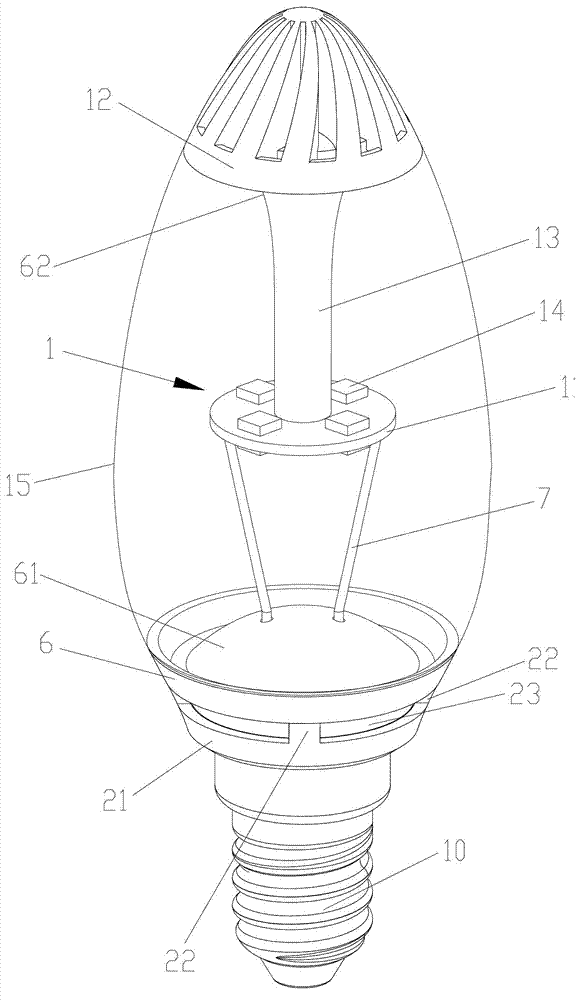

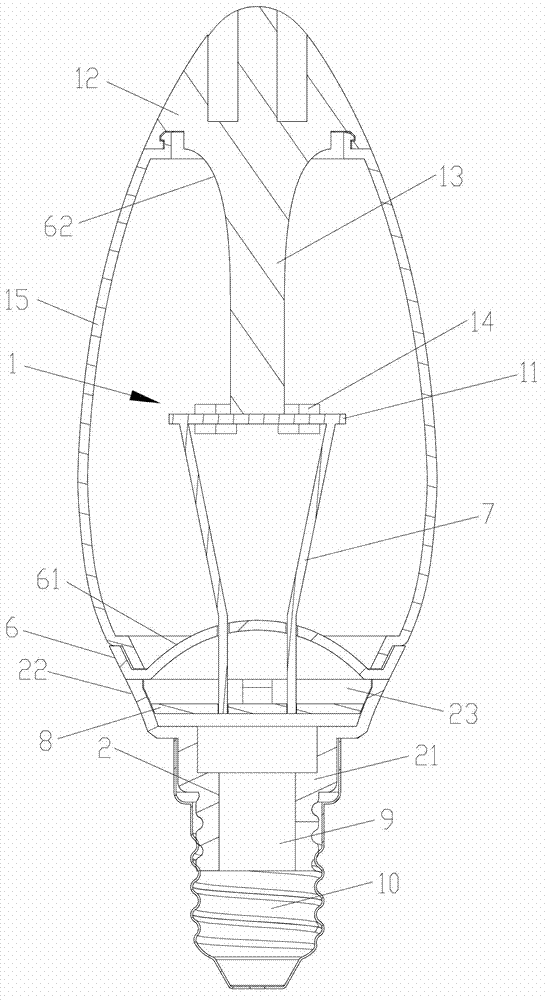

[0024] like Figure 1~3 As shown, the lighting device provided by the embodiment of the present invention includes a light source 1 and a driving power supply 2 for powering the light source 1 , and the light source 1 is mounted on a light source radiator 12 thermally isolated from a power radiator 21 . In this way, the heat dissipation of the light source 1 and the driving power supply 2 is separated, and the heat dissipation of the two is relatively independent, and no longer interacts with each other.

[0025] Usually, the top of the power radiator 21 is provided with a plurality of heat-insulating buckles 22 fixedly connected to the heat sink 6 , and gaps 23 for air flow are formed between adjacent heat-insulating buckles 22 . In this way, the air flow will quickly take away the heat transferred to the power radiator 21 and the heat sink 6, and the heat dissipation is very fast and timely.

[0026] In the embodiment of the present invention, a transparent cover 15 is prov...

Embodiment 2

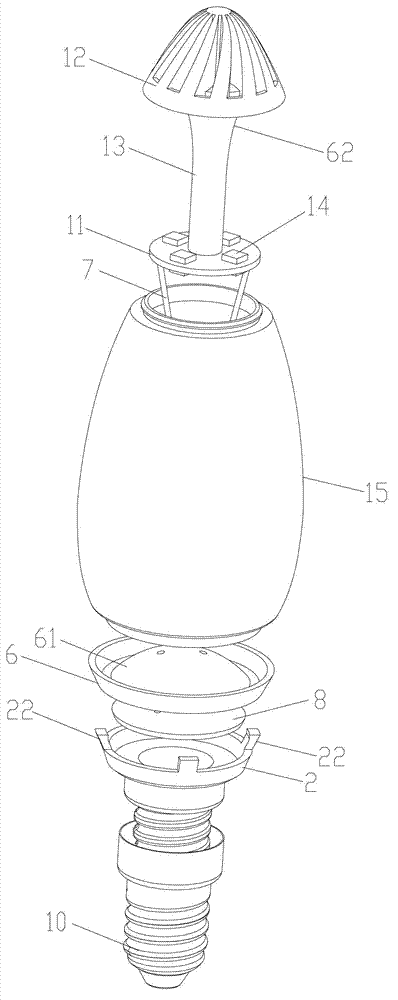

[0029] The difference from Embodiment 1 is that the heat sink 6 in this embodiment is provided with a support column 63 for supporting the light source 1, and the heat generated by the light source 1 is transmitted to the heat sink 6 through the support column 63, and then released to the surrounding air , to further improve the heat dissipation efficiency of the light source 1, such as Figure 4 shown.

Embodiment 3

[0031] like Figure 5 As shown, in this embodiment, the light source radiator 12 and heat dissipation seat 6 described in Embodiments 1 and 2 are all provided with a plurality of guide holes 16 for air flow to pass through, which is beneficial to make the heat transfer to the light source radiator 12 and heat dissipation seat 6 heat is quickly released to the air, and forms convection with the outside air, quickly taking away the heat released to the air. At this time, the guide hole 16 and the gap 23 form an all-round heat flow channel up, down, left, and right, which further improves the heat dissipation effect of the lighting device. In order to prevent the light source 1 from being polluted by impurities in the outside air, the light source 1 is covered by a protective shell 3 . Wherein, the protective shell 3 is roughly located in the middle of the light-transmitting cover 15 , so that the air between the light-transmitting cover 15 and the protective shell 3 can form st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com