Smoke recycling welding-type plate-type heat exchanger

A technology for plate heat exchangers and flue gas recovery, applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc. Small footprint, light weight, high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

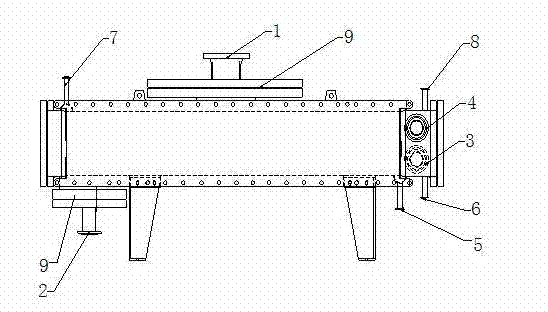

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] The flue gas recovery welded plate heat exchanger provided by the present invention includes a flue gas passage and a refrigerant passage separated by several plates welded together, and the flue gas passage includes a flue gas inlet 1, a flue gas outlet 2, a flue gas The air channel exhaust port 7 and the sewage outlet 5, the refrigerant channel includes the refrigerant inlet 3 and the refrigerant outlet 4, the refrigerant channel exhaust port 8 and the sewage outlet 6, the flue gas inlet 1 is located at the upper part of the plate heat exchanger, and the Pipe boxes 9 are respectively provided between the flue gas inlet and outlet and the channel, and between the refrigerant inlet and the connecting channel, and the tube box 9 is connected to the channel by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com